The key factors for selecting a Teflon encapsulated O-ring are the application's chemical environment, operating temperature range, and mechanical requirements. These O-rings uniquely combine the chemical inertness of a seamless Teflon jacket with the flexibility of an inner elastomeric core, such as Silicone or FKM, requiring a careful balance of both components' properties for optimal performance.

A Teflon encapsulated O-ring is a specialized hybrid seal. The selection process isn't just about choosing one material, but about matching the outer jacket to the chemical media and the inner core to the physical demands of the application.

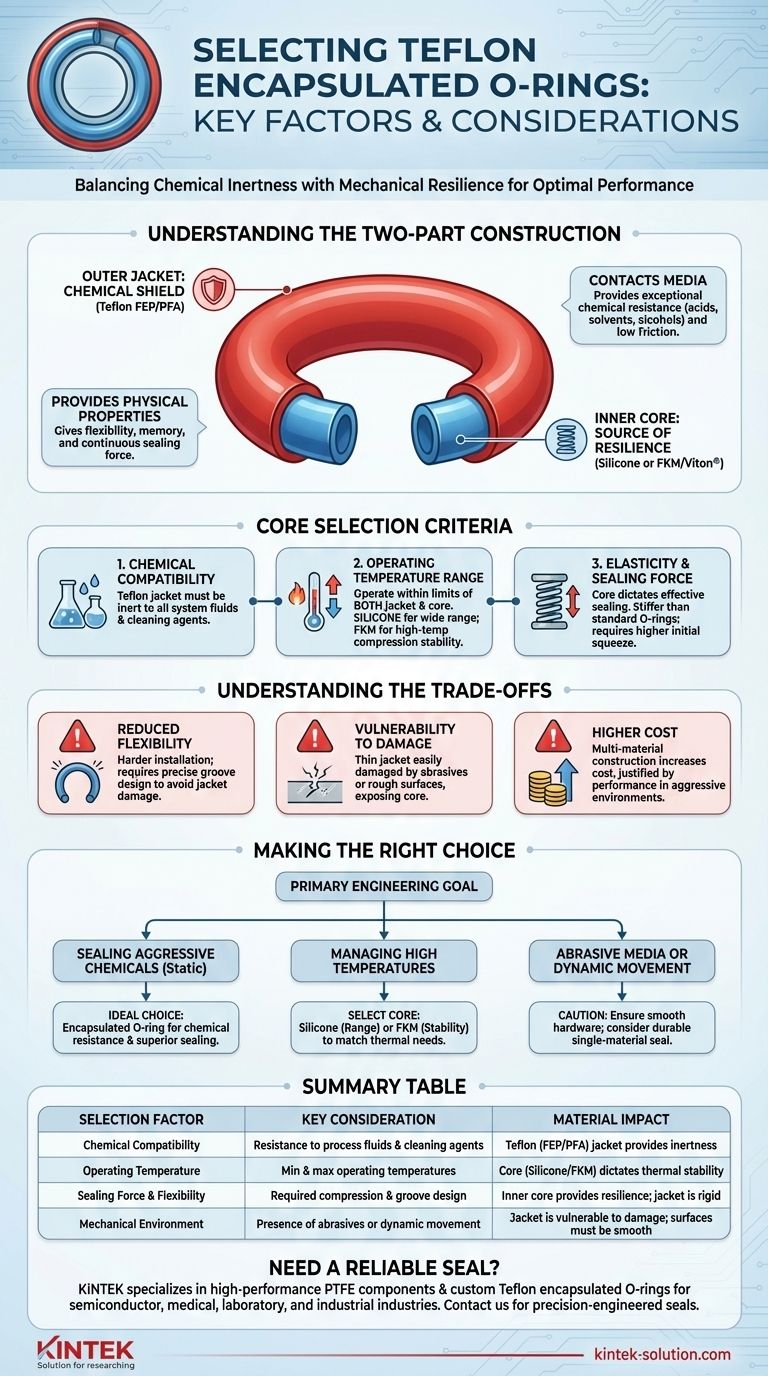

Understanding the Two-Part Construction

To make an informed choice, you must first understand that you are selecting two components that work in tandem. The performance of the O-ring is defined by the properties of both its outer jacket and its inner core.

The Outer Jacket: Your Chemical Shield

The seamless outer jacket is made of a fluoropolymer like Teflon FEP or PFA. This layer is what comes into direct contact with the process media.

Its primary role is to provide exceptional chemical resistance against a broad range of aggressive substances, including acids, solvents, and alcohols. This jacket also gives the O-ring a low-friction surface.

The Inner Core: The Source of Resilience

The inner core is a standard elastomeric O-ring, typically made of Silicone or FKM (Viton®). This core does not touch the media but provides the O-ring's physical properties.

The core gives the seal its flexibility and memory, allowing it to compress into a groove and exert a continuous sealing force. Without this resilient core, the rigid Teflon jacket would be unable to form a reliable seal.

Core Selection Criteria for Your Application

With the construction in mind, you can evaluate your application against these critical factors.

Chemical Compatibility

This is the most common reason for specifying an encapsulated O-ring. The Teflon jacket must be completely inert to all chemicals in your system. This includes process fluids as well as any cleaning or sterilization agents.

Operating Temperature Range

The entire O-ring must operate within the temperature limits of both the jacket and the core material. A Silicone core offers a very wide temperature range, while an FKM core offers superior resistance to compression set at higher temperatures.

Elasticity and Sealing Force

The core material dictates the O-ring's ability to seal effectively. You must consider the compression requirements of your hardware. Encapsulated O-rings are stiffer than standard elastomer seals and require a higher initial squeeze to function correctly.

Understanding the Trade-offs

While highly effective in specific scenarios, Teflon encapsulated O-rings are not a universal solution. Understanding their limitations is crucial for preventing seal failure.

Reduced Flexibility

Compared to a standard rubber O-ring, an encapsulated version is significantly less flexible. This can make installation more difficult and requires careful consideration of groove dimensions to ensure a proper fit without damaging the jacket.

Vulnerability to Damage

The thin Teflon jacket is the O-ring's strength and its weakness. It can be easily scratched or damaged by abrasive media, rough surface finishes in the groove, or improper installation tools. Any breach in the jacket will expose the vulnerable inner core to chemical attack, leading to rapid failure.

Higher Cost

The multi-material construction and manufacturing process make encapsulated O-rings more expensive than standard single-material elastomer seals. This cost is justified by their performance in aggressive environments where other seals would fail, reducing downtime and maintenance.

Making the Right Choice for Your System

Your final decision should be based on a clear understanding of your primary engineering goal.

- If your primary focus is sealing aggressive chemicals in a static application: An encapsulated O-ring is an ideal choice, offering the chemical resistance of solid Teflon with superior sealing ability.

- If your primary focus is managing a high-temperature environment: Select the core material (Silicone for range, FKM for stability) that best matches your thermal requirements.

- If your system involves abrasive media or dynamic movement: Proceed with caution. You must ensure hardware surfaces are smooth and consider whether a more durable, single-material seal might be more reliable.

Choosing the correct seal is a matter of precisely matching the material's capabilities to the demands of the application.

Summary Table:

| Selection Factor | Key Consideration | Material Impact |

|---|---|---|

| Chemical Compatibility | Resistance to process fluids and cleaning agents | Teflon (FEP/PFA) jacket provides inertness |

| Operating Temperature | Minimum and maximum operating temperatures | Core (Silicone/FKM) dictates thermal stability |

| Sealing Force & Flexibility | Required compression and groove design | Inner core provides resilience; jacket is rigid |

| Mechanical Environment | Presence of abrasives or dynamic movement | Jacket is vulnerable to damage; surfaces must be smooth |

Need a reliable seal for aggressive environments? KINTEK specializes in manufacturing high-performance PTFE components, including custom Teflon encapsulated O-rings. We serve semiconductor, medical, laboratory, and industrial industries, delivering precision-engineered seals that combine chemical inertness with mechanical resilience. From prototypes to high-volume orders, our custom fabrication ensures your seals meet exact application demands. Contact us today to discuss your specific requirements and enhance your system's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments