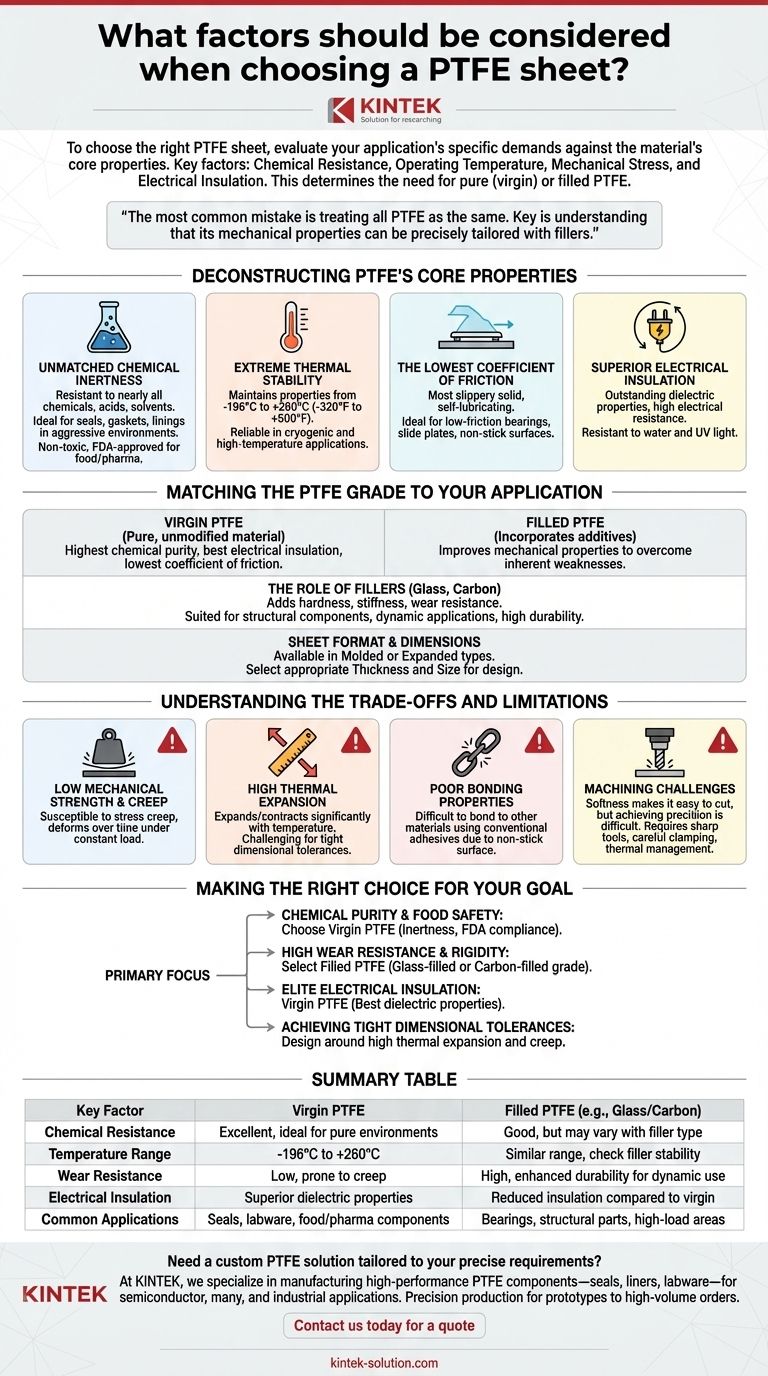

To choose the right PTFE sheet, you must evaluate your application's specific demands against the material's core properties. The primary factors to consider are the required chemical resistance, operating temperature range, mechanical stress, and electrical insulation needs, which will determine whether you need pure (virgin) PTFE or a filled grade.

The most common mistake is treating all PTFE as the same. The key is to understand that while all PTFE offers exceptional chemical and thermal resistance, its mechanical properties can be precisely tailored with fillers to meet specific performance goals like high wear resistance or rigidity.

Deconstructing PTFE's Core Properties

Understanding the fundamental characteristics of Polytetrafluoroethylene (PTFE) is the first step in making an informed decision. These inherent properties define where the material excels.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. This makes it an ideal choice for seals, gaskets, and linings in chemically aggressive environments.

Because it is non-toxic, inert, and FDA-approved for food contact, virgin PTFE is a standard material in food processing and pharmaceutical applications.

Extreme Thermal Stability

PTFE maintains its properties across an exceptionally wide operating temperature range, typically from -196°C to +260°C (-320°F to +500°F).

This stability allows it to perform reliably in applications involving cryogenic liquids or high-temperature processing without degrading.

The Lowest Coefficient of Friction

Known as the most slippery solid material, PTFE has an extremely low coefficient of friction, making it self-lubricating.

This is ideal for creating low-friction bearings, slide plates, and non-stick surfaces. Friction is influenced by pressure and speed, generally decreasing as pressure increases up to a certain point.

Superior Electrical Insulation

PTFE possesses outstanding dielectric properties and high electrical resistance, making it one of the best electrical insulators known.

Its resistance to water and UV light further enhances its reliability in electrical components, connectors, and cable insulation.

Matching the PTFE Grade to Your Application

Not all PTFE is created equal. The material can be pure or blended with additives to enhance specific characteristics, directly impacting its suitability for a given task.

Virgin vs. Filled PTFE

Virgin PTFE is pure, unmodified material. It offers the highest chemical purity, best electrical insulation, and lowest coefficient of friction.

Filled PTFE incorporates additives into the base material to improve its mechanical properties. This is done to overcome some of the inherent weaknesses of virgin PTFE.

The Role of Fillers (Glass, Carbon)

Adding fillers like glass fiber or carbon significantly increases PTFE's hardness, stiffness, and wear resistance.

These filled grades are better suited for structural components or dynamic applications that require higher durability and resistance to deformation under load.

Sheet Format and Dimensions

Finally, consider the physical form. PTFE sheets are available in various types, such as molded or expanded, and must be selected in the appropriate thickness and size for the intended design.

Understanding the Trade-offs and Limitations

To select PTFE wisely, you must also be aware of its inherent limitations. Forcing the material into an application that conflicts with its nature leads to poor performance.

Low Mechanical Strength and Creep

Virgin PTFE is a relatively soft material. It is susceptible to stress creep, meaning it can slowly deform over time when subjected to a constant load.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion. This means it expands and contracts significantly with temperature changes, making it challenging to hold tight dimensional tolerances during and after machining.

Poor Bonding Properties

The same non-stick quality that makes PTFE valuable also makes it very difficult to bond to other materials using conventional adhesives.

Machining Challenges

While its softness makes it easy to cut, achieving precision is difficult. Machinists must use extremely sharp tools, manage clamping pressure to avoid compression, and account for thermal expansion to ensure dimensional accuracy.

Making the Right Choice for Your Goal

Your final decision should be guided by the single most important performance requirement for your project.

- If your primary focus is chemical purity and food safety: Choose virgin PTFE for its inertness and FDA compliance.

- If your primary focus is high wear resistance and rigidity: Select a filled PTFE, such as a glass-filled or carbon-filled grade.

- If your primary focus is elite electrical insulation: Virgin PTFE offers the best dielectric properties and electrical resistance.

- If your primary focus is achieving tight dimensional tolerances: You must design around PTFE's high thermal expansion and tendency to creep under load.

Ultimately, selecting the correct PTFE sheet is a process of matching the material's distinct advantages to the unique challenges of your application.

Summary Table:

| Key Factor | Virgin PTFE | Filled PTFE (e.g., Glass/Carbon) |

|---|---|---|

| Chemical Resistance | Excellent, ideal for pure environments | Good, but may vary with filler type |

| Temperature Range | -196°C to +260°C | Similar range, but check filler stability |

| Wear Resistance | Low, prone to creep | High, enhanced durability for dynamic use |

| Electrical Insulation | Superior dielectric properties | Reduced insulation compared to virgin |

| Common Applications | Seals, labware, food/pharma components | Bearings, structural parts, high-load areas |

Need a custom PTFE solution tailored to your precise requirements? At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Whether you need prototypes or high-volume orders, our precision production ensures your PTFE sheet meets exact chemical, thermal, and mechanical demands. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries