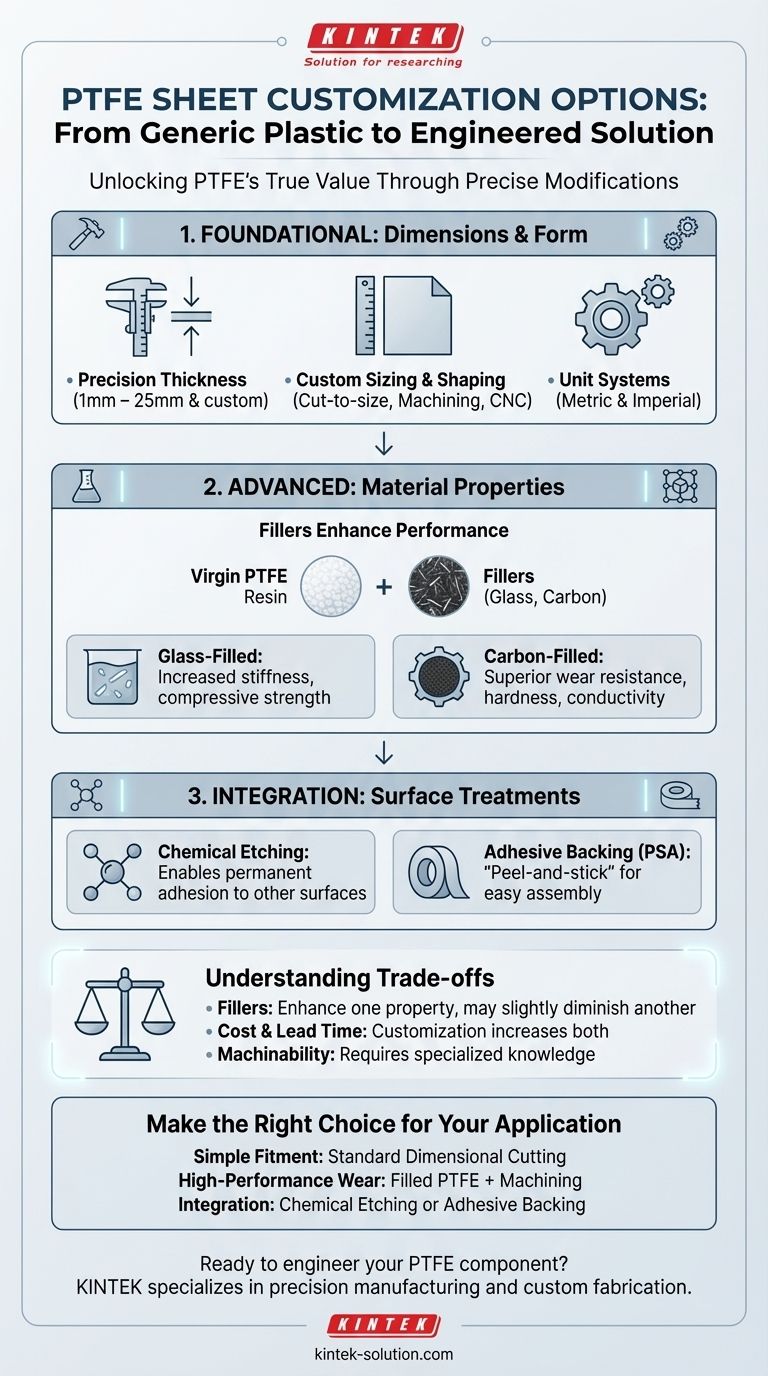

Beyond a simple sheet, Polytetrafluoroethylene (PTFE) is a highly adaptable material platform. You can customize its physical dimensions, its core material properties through fillers, and its surface for bonding or assembly. These modifications allow PTFE to be precisely engineered for applications ranging from simple gaskets to high-performance mechanical components.

PTFE’s true value is unlocked through customization. While standard sheets are useful, modifying the material’s dimensions, formulation, and surface transforms it from a generic plastic into a purpose-built engineering solution.

Foundational Customization: Dimensions and Form

The most common requirement is ensuring the material fits a specific physical space. PTFE offers extensive options for dimensional and shape customization to meet precise geometric needs.

Precision Thickness

PTFE sheets are available in a wide range of standard thicknesses, typically from 1 mm to 25 mm. Manufacturers can also produce sheets with custom, non-standard thicknesses for applications requiring exacting specifications.

Custom Sizing and Shaping

Sheets can be precisely cut-to-size using industrial methods. For thinner sheets, they can even be trimmed with basic tools like scissors for prototyping or simple fitment.

For more complex geometries, PTFE is readily machined into custom parts, components, and intricate shapes using CNC equipment.

Unit Systems (Metric vs. Imperial)

Components like washers or machined parts can be manufactured to either metric (mm) or English (inch) unit specifications, ensuring compatibility with global design standards.

Advanced Customization: Modifying Material Properties

For demanding applications, the base properties of virgin PTFE can be enhanced by compounding it with other materials. This is where PTFE evolves into a specialized performance material.

The Role of Fillers

Fillers are additives blended into the PTFE resin before it is formed into a sheet or billet. The goal is to improve specific mechanical or physical properties that virgin PTFE may lack for a particular use case.

Common Fillers and Their Impact

Adding fillers like glass or carbon fundamentally changes the material's behavior. Glass-filled PTFE offers increased stiffness and compressive strength, making it ideal for structural parts.

Carbon-filled PTFE provides superior wear resistance and hardness, making it a top choice for dynamic applications like seals and bearings. It also enhances thermal and electrical conductivity.

Surface Treatments for Integration

Pure PTFE is notoriously non-stick, which presents a challenge when you need to bond it to other surfaces. Specific surface treatments overcome this limitation.

Enabling Adhesion: Chemical Etching

A process called chemical etching can be applied to one side of a PTFE sheet. This treatment alters the surface chemistry, making it receptive to adhesives and allowing for permanent bonding to metals, plastics, and other substrates.

Simplifying Assembly: Adhesive Backing

For less demanding applications, PTFE sheets and components can be supplied with a pressure-sensitive adhesive (PSA) backing. This "peel-and-stick" option dramatically simplifies installation for gaskets, liners, and anti-friction surfaces.

Understanding the Trade-offs

While customization offers significant advantages, it's critical to understand the associated compromises.

Impact of Fillers on Core Properties

Adding fillers to enhance one property, such as hardness, can sometimes slightly diminish another, like chemical resistance or coefficient of friction. It's a balance of material science tailored to the primary need.

Cost and Lead Time

Customization naturally increases costs compared to standard, off-the-shelf sheets. Complex machining, custom-filled formulations, and secondary treatments will impact both the price and the production lead time.

Machinability Considerations

While PTFE is considered easily machinable, its softness and thermal sensitivity require specialized knowledge. Holding very tight tolerances can be challenging without experienced machinists and proper cooling techniques to prevent deformation.

Making the Right Choice for Your Application

Select your customization path based on the primary goal of your component.

- If your primary focus is simple fitment or gasketing: Start with standard dimensional cutting of virgin PTFE sheets.

- If your primary focus is high-performance mechanical wear: Specify a filled PTFE (carbon or glass) and leverage precision machining for the final shape.

- If your primary focus is integrating PTFE onto another surface: Your key options are chemical etching for permanent bonding or a pressure-sensitive adhesive backing for easier assembly.

Ultimately, viewing PTFE not as a product but as an adaptable system allows you to engineer the precise solution your project demands.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Dimensions & Form | Precision thickness, cut-to-size, CNC machining | Perfect physical fit for any space |

| Material Properties | Glass or carbon fillers | Enhanced strength, wear resistance, and hardness |

| Surface Treatment | Chemical etching, adhesive backing | Enables strong bonding and simplifies assembly |

Ready to engineer the perfect PTFE component for your project?

At KINTEK, we specialize in precision manufacturing and custom fabrication of PTFE components—from seals and liners to complex labware. Whether you need a simple prototype or a high-volume order for the semiconductor, medical, laboratory, or industrial sectors, we can help you select the right customizations (dimensions, fillers, surface treatments) to optimize performance, durability, and integration.

Contact our experts today to discuss your requirements and get a tailored solution that meets your exact specifications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications