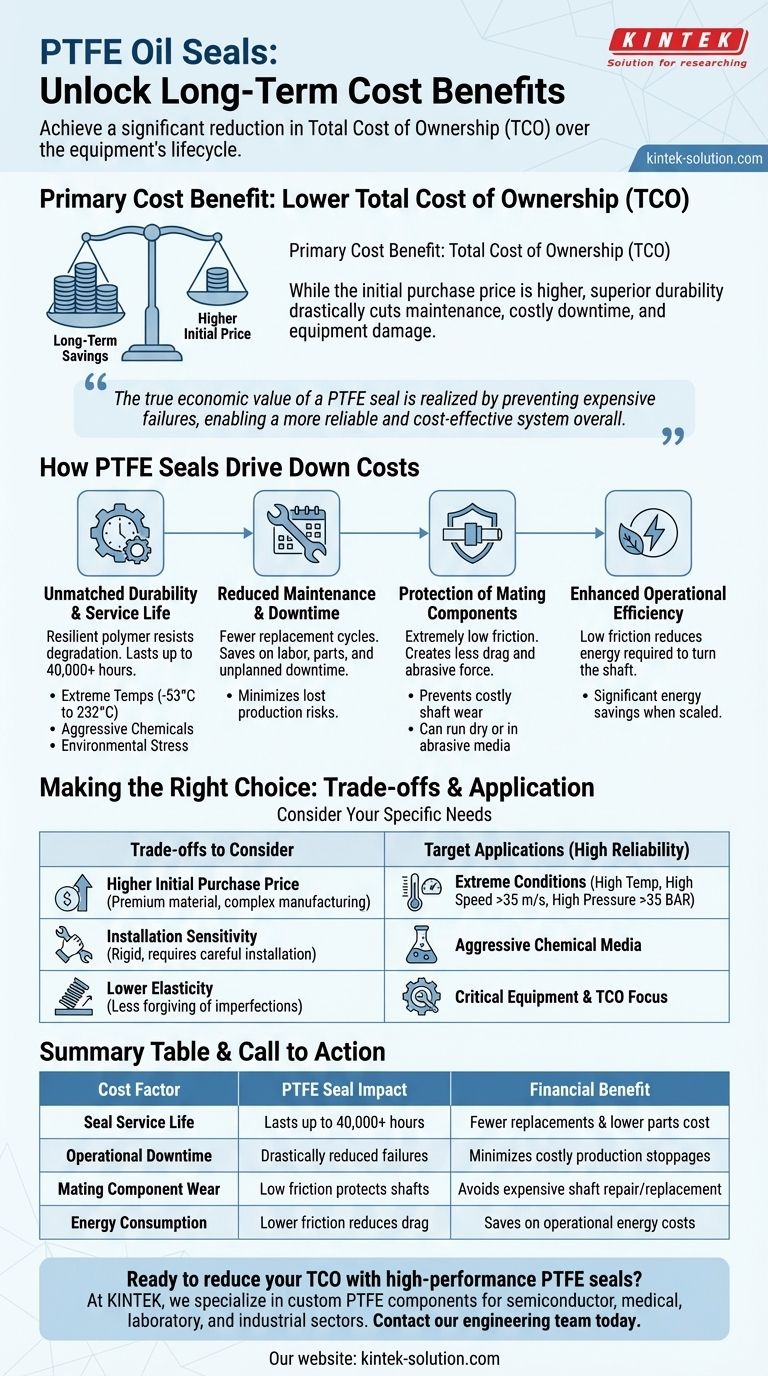

The primary cost benefit of PTFE oil seals is a significant reduction in the total cost of ownership over the equipment's lifecycle. While their initial purchase price can be higher than traditional rubber seals, they generate substantial long-term savings through superior durability, which drastically cuts down on maintenance frequency, costly operational downtime, and collateral equipment damage.

While often viewed through the lens of initial price, the true economic value of a PTFE seal is realized by preventing expensive failures. Its core benefit is not being a cheaper part, but enabling a more reliable and cost-effective system overall.

How PTFE Seals Drive Down Long-Term Costs

The financial advantages of PTFE seals stem directly from their unique material properties. These characteristics allow them to succeed where conventional elastomeric seals would degrade and fail, preventing a cascade of related expenses.

Unmatched Durability and Service Life

PTFE is an exceptionally resilient polymer. It resists degradation from factors that commonly destroy rubber seals, leading to a much longer operational life—with some applications achieving over 40,000 hours of maintenance-free service.

This durability comes from its resistance to:

- Extreme Temperatures: PTFE seals operate effectively in continuous temperatures from -53°C to 232°C (-63°F to 450°F), preventing the material from becoming brittle or soft.

- Aggressive Chemicals: The material is chemically inert, making it immune to damage from acids, solvents, and aggressive synthetic oils.

- Environmental Stress: It withstands moisture and UV exposure without degrading.

Reduced Maintenance and Downtime

A longer-lasting seal directly translates to fewer replacement cycles. This reduces costs associated with labor, new parts, and most importantly, unplanned downtime.

In industrial and automotive settings, the cost of lost production or having a critical vehicle out of service often exceeds the cost of the replacement component by orders of magnitude. The reliability of PTFE minimizes this risk.

Protection of Mating Components

PTFE has an extremely low coefficient of friction. This means it creates less drag and abrasive force on the rotating shaft it seals against.

This property saves money in two ways:

- It prevents shaft wear. A worn or grooved shaft is an expensive and time-consuming component to repair or replace. A PTFE seal protects this investment.

- It can run dry or in abrasive media. Unlike rubber seals that require lubrication to survive, PTFE's low-friction nature allows it to function with minimal lubrication, simplifying system design and preventing failure in harsh conditions.

Enhanced Operational Efficiency

The low friction of a PTFE seal also reduces the energy required to turn the shaft. While minimal for a single seal, this energy saving becomes a notable operational cost reduction when scaled across an entire facility or fleet over thousands of hours of operation.

Understanding the Trade-offs

To make an informed decision, you must also consider the specific requirements and potential challenges of using PTFE seals.

Higher Initial Purchase Price

PTFE is a premium engineering material, and manufacturing PTFE seals is a more complex process than molding standard rubber seals. This results in a higher upfront unit cost. The decision to use PTFE must be justified by the expected reduction in total lifecycle cost.

Installation Sensitivity

PTFE seals are rigid and have less "give" than their elastomeric counterparts. The seal lip can be damaged if it is not installed carefully with the correct tools. An improper installation can lead to immediate leakage, negating all the material's benefits.

Lower Elasticity

Because PTFE is not a true elastomer, it has limited elastic memory. It does not spring back into shape as readily as rubber. This means it is less forgiving of imperfections in the shaft or bore, such as significant scratches or out-of-round conditions. The hardware must be in good condition for the seal to perform optimally.

Making the Right Choice for Your Application

The decision to use a PTFE seal is an engineering choice that hinges on balancing upfront cost against long-term performance and reliability goals.

- If your primary focus is minimizing initial component cost: A standard elastomeric seal may be sufficient for non-critical applications with moderate temperatures, speeds, and clean lubricants.

- If your primary focus is reliability in extreme conditions: PTFE is the definitive choice for applications involving high temperatures, high shaft speeds (over 35 m/s), high pressure (over 35 BAR), or aggressive chemical media.

- If your primary focus is reducing total cost of ownership (TCO): PTFE provides exceptional value by preventing costly downtime, protecting expensive hardware like shafts, and minimizing maintenance labor in critical equipment.

By investing in the right material for the job, you shift your strategy from reactive maintenance to proactive system reliability.

Summary Table:

| Cost Factor | PTFE Seal Impact | Financial Benefit |

|---|---|---|

| Seal Service Life | Lasts up to 40,000+ hours | Fewer replacements & lower parts cost |

| Operational Downtime | Drastically reduced failures | Minimizes costly production stoppages |

| Mating Component Wear | Low friction protects shafts | Avoids expensive shaft repair/replacement |

| Energy Consumption | Lower friction reduces drag | Saves on operational energy costs |

Ready to reduce your total cost of ownership with precision-engineered PTFE seals?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact sealing solution your application demands.

Contact our engineering team today to discuss how our durable PTFE seals can enhance your system reliability and deliver significant long-term savings.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application