At its core, wear and tear in PTFE butterfly valves stem from three primary factors: mechanical abrasion from the fluid media, the physical stress of normal operation over time, and improper selection for the specific application. While PTFE offers outstanding chemical resistance, its physical properties are not immune to degradation when mismatched with operational demands.

The central challenge is recognizing that PTFE's exceptional chemical resilience does not equate to invulnerability against physical wear. Most failures occur not from chemical attack, but from mechanical forces like abrasion or operational stress that are overlooked during valve selection.

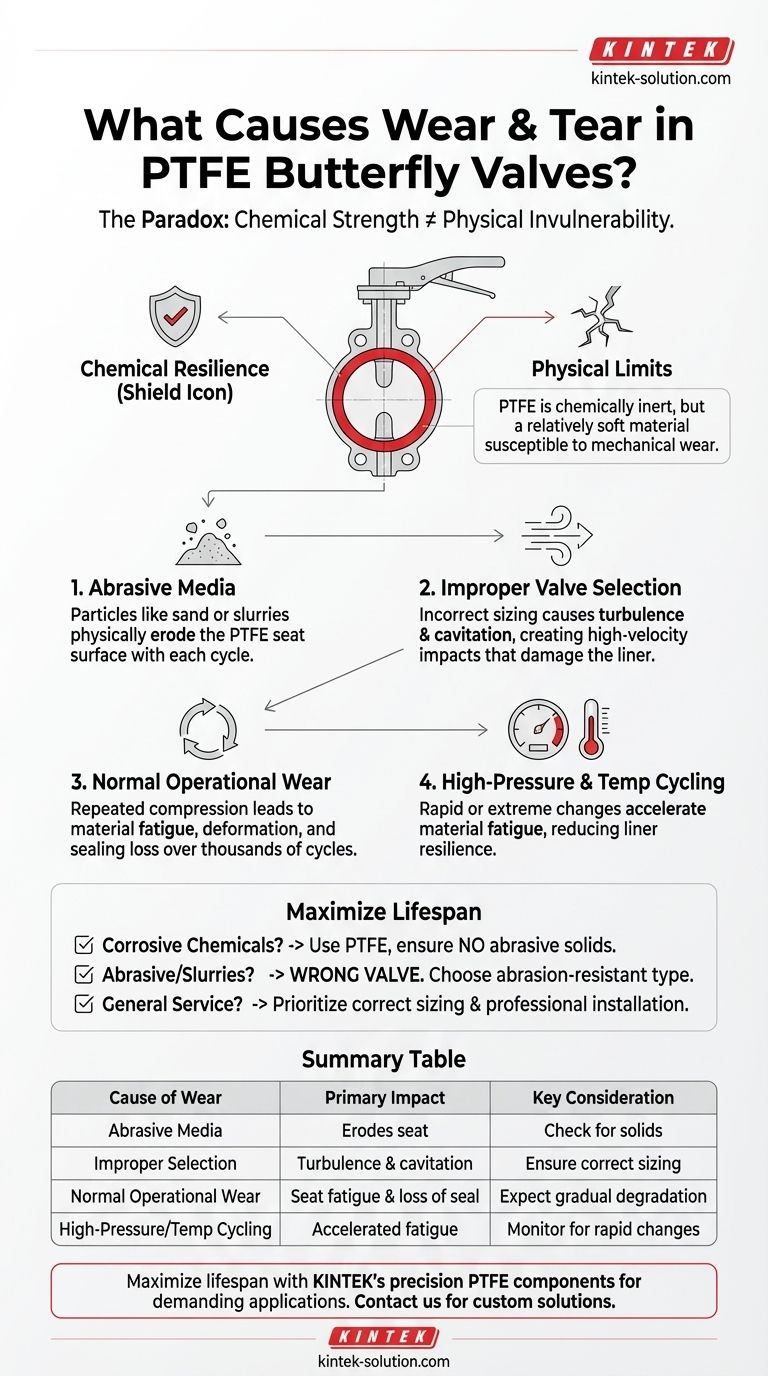

The Paradox of PTFE: Chemical Strength vs. Physical Limits

PTFE (polytetrafluoroethylene) is specified for its remarkable durability in harsh environments. However, understanding its specific strengths and weaknesses is crucial for predicting its service life.

Understanding PTFE's Core Resilience

PTFE's primary advantage is its chemical inertness. Its thick, non-metallic lining provides a robust barrier against corrosion and chemical attack, even at extreme temperatures.

This property protects not only the valve seat but also insulates other metal components within the system, significantly increasing the valve's lifespan in corrosive applications.

The Achilles' Heel: Mechanical Wear

Despite its chemical strength, PTFE is a relatively soft material. This makes it susceptible to mechanical wear, particularly from abrasive particles suspended in the fluid.

Slurries, sand, or other particulates can physically scrape and erode the PTFE seat over time, compromising the valve's ability to create a tight seal.

Primary Causes of PTFE Valve Degradation

While every valve experiences normal wear, certain conditions dramatically accelerate the process for PTFE-lined components.

Abrasive Media

This is the most common cause of premature failure. A fluid that is chemically compatible with PTFE can still destroy the valve if it contains abrasive solids. These particles physically wear away the seating surface with each cycle.

Improper Valve Selection

Choosing a valve that is not correctly sized for the flow rate can create turbulence and cavitation. These phenomena can generate high-velocity impacts that physically damage the PTFE liner, even without abrasive particles.

Normal Operational Wear

Every time the valve opens and closes, the disc compresses the PTFE seat. Over thousands of cycles, this repeated stress can lead to material fatigue, deformation, and an eventual loss of sealing capability.

High-Pressure and Temperature Cycling

While PTFE has a wide operating temperature range, rapid or extreme cycling between temperature and pressure points can accelerate material fatigue, causing the liner to lose its resilience more quickly.

Understanding the Trade-offs

Selecting a PTFE valve involves balancing its superior chemical resistance against its physical limitations and cost.

PTFE vs. Other Elastomers

For applications involving water or steam, an elastomer like EPDM may offer excellent performance at a lower cost. PTFE is the superior choice for harsh chemical environments, but it is over-specified for simpler applications where abrasion is not a concern.

Recognizing Early Symptoms of Failure

The first signs of wear are often subtle. A gradual increase in the torque required to operate the valve or minor, intermittent leakage are clear indicators that the PTFE seat's integrity has been compromised.

The Importance of Proactive Inspection

Regular maintenance and inspection are critical. Visual checks for seat erosion and operational tests for smooth actuation can identify developing issues before they lead to a critical failure.

How to Maximize Valve Lifespan

Making the right choice depends entirely on the specific demands of your system.

- If your primary focus is handling highly corrosive chemicals: PTFE is an excellent choice, but ensure your fluid is free of abrasive solids to prevent mechanical erosion.

- If your primary focus is managing slurries or abrasive fluids: A standard PTFE-lined butterfly valve is likely the wrong choice; consider a valve designed for abrasion, such as a knife gate or a specially lined ball valve.

- If your primary focus is maximizing reliability in general service: Prioritize correct valve sizing and professional installation to avoid turbulence and uneven seat wear from the outset.

By matching the valve's material strengths to the specific mechanical and chemical demands of your system, you transform a component into a long-term, reliable asset.

Summary Table:

| Cause of Wear | Primary Impact | Key Consideration |

|---|---|---|

| Abrasive Media | Erodes PTFE seat surface | Check for solids in fluid (e.g., slurries, sand) |

| Improper Valve Selection | Turbulence & cavitation damage | Ensure correct sizing for flow rate |

| Normal Operational Wear | Seat fatigue & loss of seal | Expect gradual degradation over cycles |

| High-Pressure/Temperature Cycling | Accelerated material fatigue | Monitor for rapid changes in conditions |

Maximize the lifespan and reliability of your fluid handling systems with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, and labware are engineered for superior performance in the most demanding semiconductor, medical, laboratory, and industrial applications. We help you select the right material and design to combat wear, ensuring long-term durability and preventing costly unplanned downtime.

Contact KINTEK today for a consultation on custom PTFE solutions—from prototypes to high-volume orders—and transform your components into reliable assets.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application