In the automotive industry, Polytetrafluoroethylene (PTFE) is a critical high-performance polymer used for components that must withstand extreme conditions. Its primary applications are in sealing and fluid transfer, including gaskets, O-rings, valve stem seals, and linings for fuel and transmission hoses, where its unique properties ensure vehicle reliability and longevity.

The core reason PTFE is indispensable in automotive engineering is its rare combination of three key properties: extreme temperature resistance, near-total immunity to corrosive automotive fluids, and an exceptionally low coefficient of friction. This makes it the ideal material for sealing critical systems and ensuring their efficient, long-term operation.

Why PTFE is a Go-To Material for Vehicle Systems

PTFE isn't chosen for its low cost; it's chosen because it solves engineering problems that other materials cannot. Its value comes from its ability to perform reliably under the harsh conditions found within a modern vehicle.

Resisting Extreme Temperatures

Engine compartments and transmission systems generate immense heat. Materials in these environments must maintain their structural integrity and sealing properties without melting, cracking, or degrading.

PTFE has an exceptionally high melting point and a wide operating temperature range, making it perfectly suited for engine seals, gaskets, and other high-heat components.

Neutralizing Corrosive Fluids

A vehicle relies on a host of aggressive fluids, including gasoline, ethanol blends, motor oil, and transmission fluid. These chemicals can quickly break down conventional rubber and plastic parts.

PTFE is chemically inert, meaning it does not react with these corrosive substances. This is why it's the preferred material for linings in fuel hoses and seals in direct contact with lubricants.

Reducing Friction and Wear

Efficiency and durability are paramount in automotive design. Components that move against each other, such as rotating shafts, create friction, which leads to wear and energy loss.

With one of the lowest coefficients of friction of any solid material, PTFE creates ultra-slick, non-stick surfaces. This property is vital for shaft seals and valve stem seals, reducing wear and improving the mechanical efficiency of the engine and transmission.

Ensuring a Leak-Proof Seal

Preventing fluid and gas leaks is fundamental to vehicle safety and performance. Gaskets and O-rings must create a perfect seal and maintain it over thousands of miles and countless temperature cycles.

The durability and chemical resistance of PTFE make it an ideal material for creating long-lasting, leak-proof gaskets and seals that won't become brittle or fail when exposed to harsh automotive environments.

Common Automotive Applications of PTFE

PTFE's properties translate directly into specific, high-value applications throughout the vehicle.

Fluid and Fuel Systems

Modern fuels and lubricants require robust components. PTFE linings are used in fuel hoses, power steering lines, and transmission fluid lines to prevent the hose material from degrading and to stop fuel vapors from permeating through the hose wall.

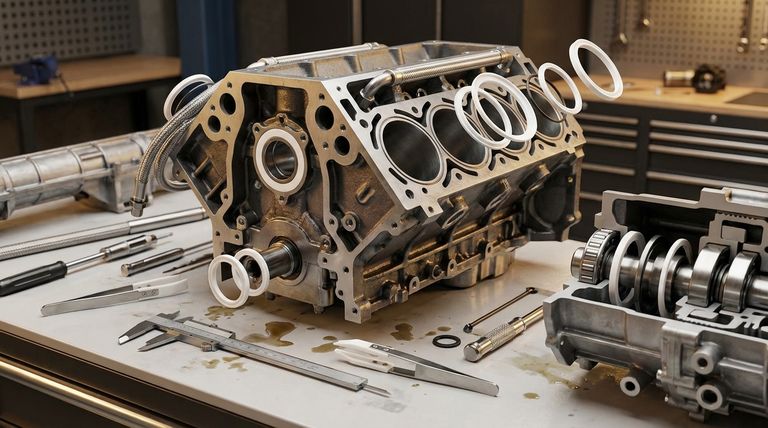

Engine and Transmission Components

This is where PTFE's high-temperature and low-friction capabilities are most critical. It is fabricated into O-rings, gaskets, valve stem seals, and shaft seals to prevent oil leaks and ensure internal components operate smoothly.

Exterior and Water-Repellent Components

While less common, PTFE's hydrophobic (water-repellent) nature makes it useful as a coating on certain exterior components. This helps protect parts from environmental damage and corrosion by repelling water and grime.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE offers exceptional performance, its selection involves considering key trade-offs.

Higher Material Cost

PTFE is a premium polymer, and its cost is higher than that of common elastomers like nitrile or neoprene rubber. Its use is typically justified in applications where lower-cost materials would fail prematurely.

Susceptibility to Creep

In its pure form, PTFE can be prone to "creep" or cold flow, meaning it can slowly deform over time when under a constant mechanical load. To counteract this, it is often blended with fillers like glass fiber or carbon to create a filled PTFE compound, which significantly improves its strength and rigidity.

Manufacturing Complexity

Compared to materials that can be easily injection molded, manufacturing complex PTFE parts can be a more involved and costly process. This can influence the design and final cost of the automotive component.

Making the Right Choice for Your Goal

The decision to use PTFE depends entirely on the performance demands of the specific automotive application.

- If your primary focus is reliability in high-heat, high-friction areas: PTFE or a filled PTFE compound is the superior choice for components like engine shaft seals due to its unmatched thermal stability.

- If your primary focus is containing aggressive modern fluids: PTFE's chemical inertness makes it essential for fuel hose liners and transmission seals to prevent material degradation and leaks.

- If your primary focus is a simple, low-cost seal in a less demanding environment: A standard elastomer may be sufficient, as the high-performance benefits of PTFE would be unnecessary and not cost-effective.

Ultimately, PTFE's unique properties are a key enabler of the high performance, efficiency, and durability expected from modern vehicles.

Summary Table:

| Key Property | Automotive Application | Benefit |

|---|---|---|

| Extreme Temperature Resistance | Engine & Transmission Seals, Gaskets | Maintains integrity and sealing under high heat |

| Chemical Inertness | Fuel Hose Liners, Fluid System Seals | Resists degradation from gasoline, oil, and other fluids |

| Low Coefficient of Friction | Shaft Seals, Valve Stem Seals | Reduces wear and improves mechanical efficiency |

| Durability | O-rings, Gaskets | Creates long-lasting, leak-proof seals over countless cycles |

Need High-Performance PTFE Components for Your Automotive Applications?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and gaskets—for the demanding environments of the automotive industry. Our expertise ensures your components meet the highest standards for heat resistance, chemical compatibility, and durability.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Solutions using pure or filled PTFE compounds to meet specific performance needs, such as combating creep.

- Industry Focus: Dedicated support for automotive, semiconductor, medical, laboratory, and other specialized industries.

Let us help you enhance the reliability and longevity of your vehicle systems.

Contact KINTEK today for a consultation to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability