At its core, a PTFE O-ring is defined by its extreme resilience to chemical and thermal degradation. Unlike common elastomer (rubber) seals, its unique properties stem from its rigid, non-elastomeric fluoropolymer composition. This gives it near-universal chemical inertness, an exceptionally wide operating temperature range from cryogenic levels to high heat, and a naturally low-friction surface.

The crucial distinction is that standard elastomer O-rings rely on physical flexibility and "memory" to seal, while PTFE O-rings rely on extreme material stability. This makes PTFE a specialized solution for environments where rubber would instantly fail, but also introduces critical mechanical trade-offs you must consider.

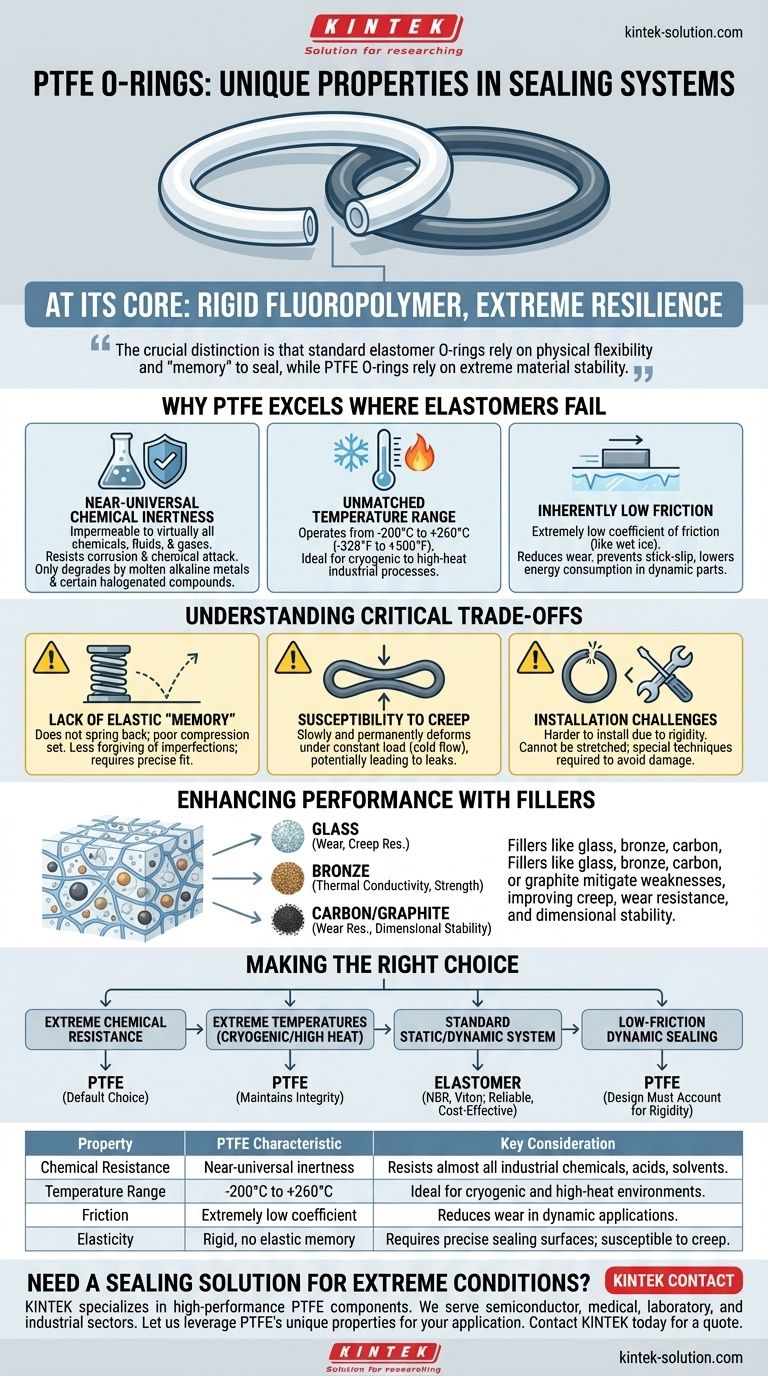

Why PTFE Excels Where Elastomers Fail

PTFE (Polytetrafluoroethylene) is not a type of rubber; it is a rigid plastic. This fundamental difference is the source of its most powerful advantages in demanding sealing applications.

Near-Universal Chemical Inertness

PTFE is impermeable to virtually all industrial chemicals, fluids, and gases. Its molecular structure is incredibly stable, making it highly resistant to corrosion and chemical attack.

Only a few rare substances, such as molten alkaline metals and certain halogenated compounds, can degrade it. For nearly all other applications, it is considered completely inert.

An Unmatched Operational Temperature Range

PTFE seals maintain their integrity in conditions that would cause elastomers to become brittle or melt. They are a primary choice for both high-temperature processes and cryogenic applications.

The material functions effectively in a vast range, typically from -200°C to +260°C (-328°F to +500°F). This makes it ideal for everything from liquid nitrogen systems to industrial ovens and combustion processes.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" characteristic is invaluable in dynamic applications where parts must move against the seal.

This property reduces wear, prevents stick-slip behavior, and lowers the energy required for movement in rotating or reciprocating parts.

Understanding the Critical Trade-offs

The rigidity that gives PTFE its strengths also creates its primary weaknesses. Choosing PTFE without understanding these limitations can lead to seal failure.

Lack of Elastic "Memory"

Because PTFE is not an elastomer, it does not spring back to its original shape after being compressed. This poor "compression set" means it is less forgiving of imperfections in the sealing surfaces.

A standard rubber O-ring can compensate for minor scratches or fluctuations in pressure, but a PTFE seal requires a precise fit and cannot dynamically adjust as well.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, PTFE can slowly and permanently deform. This phenomenon, known as creep or cold flow, can reduce the sealing force over time and eventually lead to leaks.

Installation Challenges

PTFE's lack of elasticity makes it much harder to install than a flexible rubber O-ring. It cannot be stretched over components easily, and forcing it can cause permanent damage or nicks that compromise the seal. Special installation techniques are often required.

Enhancing Performance with Fillers

To mitigate some of PTFE's mechanical weaknesses, it is often blended with other materials. These fillers can significantly improve its performance characteristics.

Why Add Fillers?

Fillers are used to improve properties like creep resistance, dimensional stability, and wear resistance. By adding a reinforcing agent to the PTFE matrix, the final product becomes more robust.

Common Filler Materials

Common fillers include glass, bronze, carbon, or graphite. For example, glass-filled PTFE has enhanced wear and creep resistance, while bronze-filled PTFE offers better thermal conductivity and strength.

Making the Right Choice for Your Sealing Application

Selecting the correct O-ring material is a critical design decision. Use the following guidelines to determine if PTFE is the appropriate choice for your specific goal.

- If your primary focus is extreme chemical resistance: PTFE is the default choice for sealing aggressive solvents, acids, and other corrosive media.

- If your primary focus is extreme temperatures (cryogenic or high heat): PTFE is one of the few materials that can maintain its integrity at both ends of the temperature spectrum.

- If your primary focus is a standard static or dynamic system: A standard elastomer like NBR or Viton is often more reliable and cost-effective due to its superior elasticity and sealing forgiveness.

- If your primary focus is low-friction dynamic sealing: PTFE is a strong candidate, but the hardware design must account for its rigidity and poor compression set.

By understanding these distinct properties and limitations, you can leverage PTFE not as a general-purpose replacement for rubber, but as a precise engineering solution for the most demanding environments.

Summary Table:

| Property | PTFE O-Ring Characteristic | Key Consideration |

|---|---|---|

| Chemical Resistance | Near-universal inertness | Resists almost all industrial chemicals, acids, and solvents. |

| Temperature Range | -200°C to +260°C | Ideal for cryogenic and high-heat environments. |

| Friction | Extremely low coefficient | Reduces wear in dynamic applications. |

| Elasticity | Rigid, no elastic memory | Requires precise sealing surfaces; susceptible to creep. |

Need a Sealing Solution for Extreme Conditions?

PTFE O-rings are a specialized tool for demanding applications where standard elastomers fail. Selecting the right material and design is critical to your system's performance and longevity.

KINTEK specializes in manufacturing high-performance PTFE components, including precision O-rings, seals, and custom fabrications. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

Let us help you leverage PTFE's unique properties effectively. Our expertise ensures you get a seal that meets your exact requirements for chemical resistance, temperature stability, and low friction.

Contact KINTEK today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments