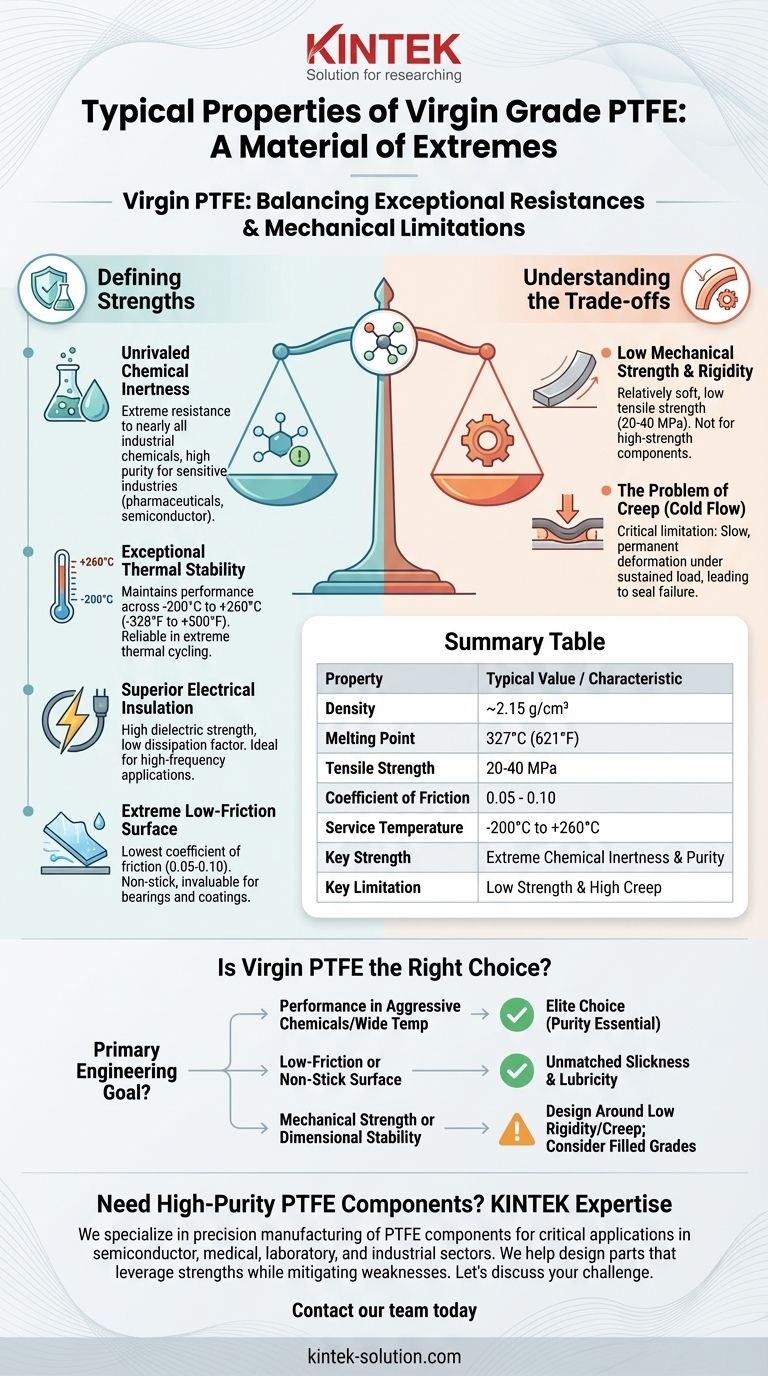

At its core, virgin grade Polytetrafluoroethylene (PTFE) is a material of extremes. It is a pure, white, and opaque fluoropolymer known for its exceptional chemical inertness, wide temperature stability, and extremely low friction. Typical properties include a density of approximately 2.15 g/cm³, a high melting point of 327°C (621°F), and a tensile strength between 20-40 MPa. Its coefficient of friction is remarkably low, ranging from 0.05 to 0.10.

Virgin PTFE is best understood as a high-performance problem-solver for extreme environments, not as a structural material. Its world-class chemical, thermal, and electrical resistance is balanced by significant mechanical limitations, particularly low strength and a tendency to deform under load.

The Defining Strengths of Virgin PTFE

To understand if virgin PTFE is the right choice, you must first appreciate its unique combination of resistances. These properties are why it is specified for some of the most demanding applications.

Unrivaled Chemical Inertness

Virgin PTFE is almost completely inert, offering extreme resistance to nearly all industrial chemicals, including aggressive acids, bases, and solvents.

Because it contains no fillers or additives, its high purity makes it a default choice for sensitive industries like pharmaceuticals, food and beverage, and semiconductor manufacturing where contamination is not an option.

Exceptional Thermal Stability

This material maintains its integrity and performance across an incredibly wide service temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Unlike many other polymers, it does not become brittle at cryogenic temperatures or degrade at high heat within this range, ensuring reliable performance in extreme thermal cycling applications.

Superior Electrical Insulation

PTFE is one of the best known electrical insulators. It possesses a high dielectric strength and a low dissipation factor.

This makes it an ideal material for high-frequency applications, cable insulation, and critical electronic components where preventing electrical leakage is paramount.

Extreme Low-Friction Surface

Virgin PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This results in an exceptionally non-stick surface, making it invaluable for coatings on cookware, low-friction bearings, and any application where smooth, effortless sliding is required.

Understanding the Trade-offs: Mechanical Limitations

The elite performance of virgin PTFE comes with significant trade-offs. Its primary weaknesses are mechanical, and failing to account for them is a common source of engineering failure.

Low Mechanical Strength and Rigidity

Compared to other engineering plastics, virgin PTFE is a relatively soft material.

Its tensile strength of 20-40 MPa is low, and it has very little rigidity. It should not be used for components that require high strength or structural integrity.

The Problem of Creep (Cold Flow)

This is the most critical limitation of virgin PTFE. Creep, or "cold flow," is the tendency of the material to slowly and permanently deform when subjected to a sustained load, even at room temperature.

For applications like seals and gaskets, this means that under constant compression, the material may slowly flow out of position, leading to a loss of sealing pressure and eventual failure.

High Elongation and Impact Resistance

While its strength is low, virgin PTFE is highly flexible, with an elongation at break between 200-500%.

This flexibility, combined with its inertness, gives it high impact resistance. It will deform or stretch rather than shatter upon impact.

Is Virgin PTFE the Right Choice for Your Application?

Choosing this material requires a clear understanding of your primary engineering goal.

- If your primary focus is performance in aggressive chemical or wide temperature environments: Virgin PTFE is an elite choice, especially where purity is essential for the application.

- If your primary focus is creating a low-friction or non-stick surface: The slickness and lubricity of virgin PTFE are nearly unmatched by any other polymer.

- If your primary focus is mechanical strength or dimensional stability under load: You must design around virgin PTFE's low rigidity and tendency to creep; other materials or filled PTFE grades are often better suited for these tasks.

Understanding both its exceptional resistances and its inherent mechanical weaknesses is the key to successfully leveraging virgin PTFE in your design.

Summary Table:

| Property | Typical Value / Characteristic |

|---|---|

| Density | ~2.15 g/cm³ |

| Melting Point | 327°C (621°F) |

| Tensile Strength | 20-40 MPa |

| Coefficient of Friction | 0.05 - 0.10 |

| Service Temperature | -200°C to +260°C |

| Key Strength | Extreme Chemical Inertness & Purity |

| Key Limitation | Low Strength & High Creep (Cold Flow) |

Need High-Purity PTFE Components for Demanding Applications?

Virgin PTFE's unique combination of extreme chemical resistance, thermal stability, and non-stick properties makes it ideal for critical applications in the semiconductor, medical, laboratory, and industrial sectors. However, its mechanical limitations require expert design and fabrication.

At KINTEK, we specialize in precision manufacturing of PTFE components—from custom seals and liners to complex labware. We understand the material's trade-offs and can help you design parts that leverage its strengths while mitigating weaknesses, whether you need prototypes or high-volume production.

Let's discuss how our expertise can solve your specific challenge. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech