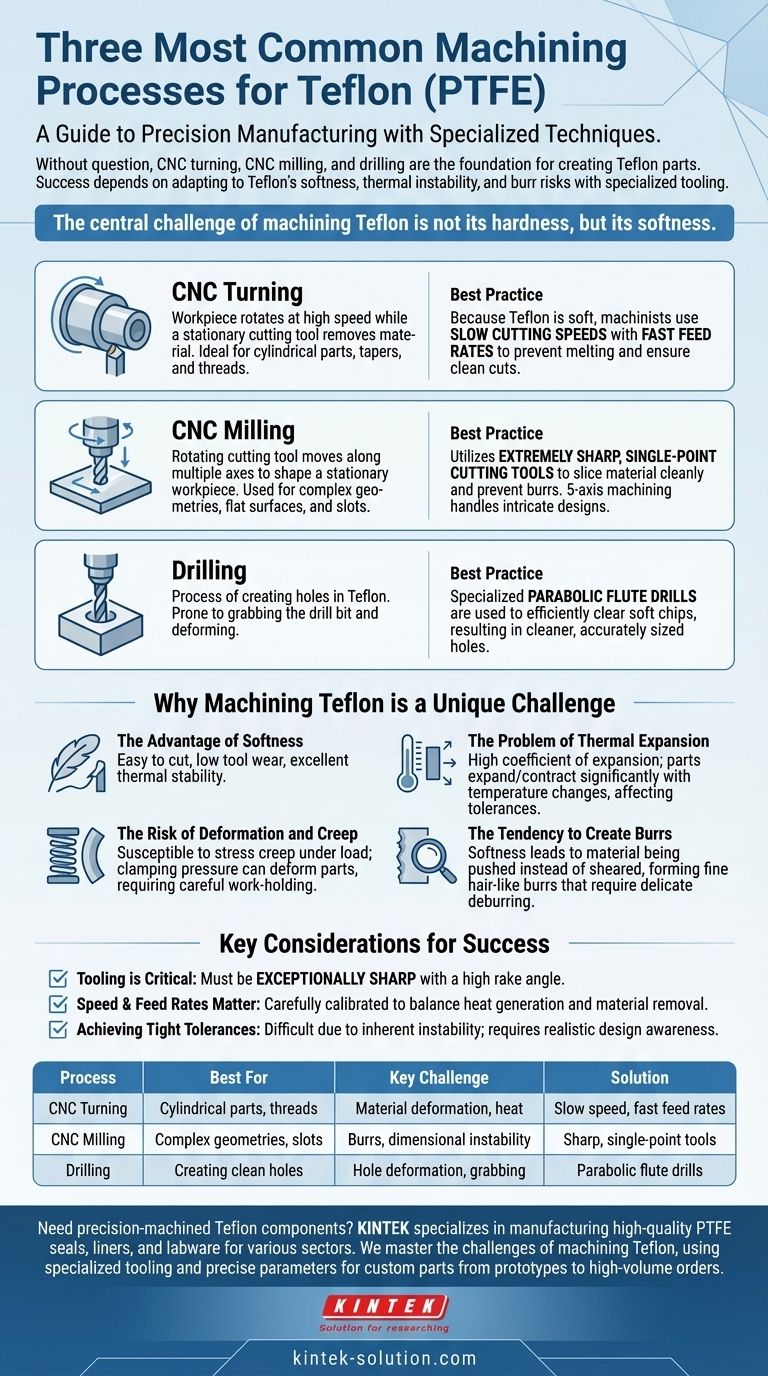

Without question, the three most common machining processes for Teflon (PTFE) are CNC turning, CNC milling, and drilling. These methods are the foundation for creating everything from simple washers to complex custom components, but success depends entirely on adapting the techniques to Teflon's unique properties.

The central challenge of machining Teflon is not its hardness, but its softness. While it is easy to cut, its thermal instability, tendency to deform under pressure, and risk of burrs mean that precision requires specialized tooling and careful control of machining parameters.

A Closer Look at the Core Processes

Each of the primary machining methods is adapted to leverage specific tool and workpiece movements to achieve the desired shape.

CNC Turning

In CNC turning, the Teflon workpiece is rotated at high speed while a stationary cutting tool removes material. This process is ideal for creating cylindrical parts, tapers, and threaded components.

Because Teflon is soft, machinists often use slow cutting speeds combined with fast feed rates to produce a clean cut without melting or deforming the material.

CNC Milling

CNC milling operates on the opposite principle: the cutting tool rotates while the workpiece is held stationary. The tool moves along multiple axes to remove material and shape the part.

This method is used for creating more complex geometries, including flat surfaces, slots, and custom contours. Using extremely sharp, single-point cutting tools is critical to slice the material cleanly rather than pushing it, which prevents burrs. For highly intricate designs, 5-axis CNC machining is often employed.

Drilling

Drilling is the process of creating holes in a Teflon part. While seemingly straightforward, Teflon’s softness makes it prone to grabbing the drill bit and deforming the hole.

To counteract this, specialized parabolic flute drills are often used. Their design is more efficient at clearing away the soft Teflon chips, resulting in a cleaner and more accurately sized hole.

Why Machining Teflon is a Unique Challenge

Teflon’s physical properties present a distinct set of advantages and disadvantages that every machinist must account for.

The Advantage of Softness

Teflon's low hardness makes it exceptionally easy to cut, reducing tool wear and machining time compared to metals or harder plastics.

Its excellent thermal stability also means it doesn't get sticky or clog tools when heated by friction, which simplifies the cutting process.

The Problem of Thermal Expansion

Teflon has a very high coefficient of thermal expansion. This means it expands and contracts significantly with even minor temperature changes caused by the machining process.

This instability makes holding tight tolerances a primary challenge, as a part might measure correctly when warm but be out of spec once it cools to room temperature.

The Risk of Deformation and Creep

The material is susceptible to stress creep, meaning it can slowly deform over time when a load is applied. During machining, the pressure from clamping or cutting can easily deform the part.

This lack of rigidity and poor dimensional stability requires careful work-holding strategies and minimal tool pressure to avoid distorting the final component.

The Tendency to Create Burrs

Because Teflon is so soft, tools can sometimes push the material aside instead of shearing it cleanly. This results in fine, hair-like burrs along the cut edges.

Deburring these parts adds an extra step to the process and requires a delicate touch to avoid damaging the component's surface.

Understanding the Trade-offs and Key Considerations

Successfully machining Teflon involves balancing its benefits with its limitations. Ignoring these factors often leads to scrapped parts and project delays.

Tooling is Critical

The single most important factor is using the right tool. Tools must be exceptionally sharp with a high rake angle to slice, not push, the material. Dull tools are the primary cause of burrs and dimensional inaccuracy.

Speed and Feed Rates Matter

Machining parameters must be carefully calibrated. Pushing the tool too fast or generating too much friction can introduce heat, leading to thermal expansion and inaccurate cuts. The right balance ensures a clean, stable cut.

Achieving Tight Tolerances is Difficult

Engineers must design parts with an awareness of Teflon's limitations. Attempting to hold tolerances that are routine for aluminum or steel is often impractical and expensive with Teflon due to its inherent instability.

Making the Right Choice for Your Goal

Select your approach based on the specific requirements of your component.

- If your primary focus is high-precision, complex geometries: Rely on multi-axis CNC milling with extremely sharp tooling and a plan to manage thermal expansion.

- If your primary focus is simple cylindrical or symmetrical parts: CNC turning is the most direct and efficient method, provided feed and speed rates are optimized.

- If your primary focus is creating clean, precise holes: Use specialized parabolic drills and minimal pressure to prevent material deformation and ensure accuracy.

Ultimately, mastering Teflon machining comes from respecting the material's properties rather than fighting against them.

Summary Table:

| Process | Best For | Key Challenge | Solution |

|---|---|---|---|

| CNC Turning | Cylindrical parts, threads | Material deformation, heat | Slow speed, fast feed rates |

| CNC Milling | Complex geometries, slots | Burrs, dimensional instability | Sharp, single-point tools |

| Drilling | Creating clean holes | Hole deformation, grabbing | Parabolic flute drills |

Need precision-machined Teflon components? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We master the unique challenges of machining Teflon, using specialized tooling and precise parameters to deliver custom parts from prototypes to high-volume orders. Contact us today to discuss your project requirements and benefit from our expertise in precision production!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability