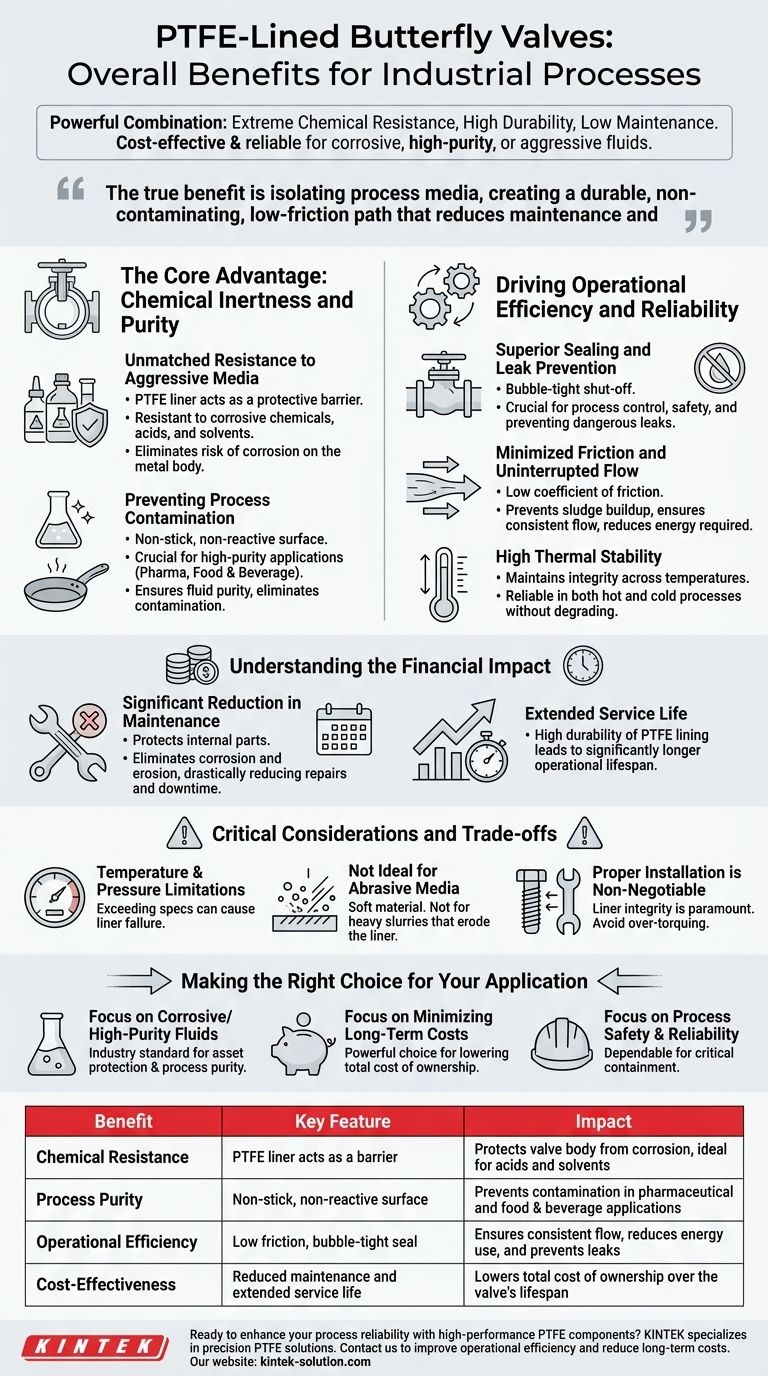

In short, PTFE-lined butterfly valves offer a powerful combination of extreme chemical resistance, high durability, and low maintenance requirements. This makes them a cost-effective and highly reliable solution for controlling the flow of corrosive, high-purity, or aggressive fluids in demanding industrial environments.

The true benefit of a PTFE-lined butterfly valve is not just its material properties, but its ability to isolate the process media from the valve body. This creates a durable, non-contaminating, and low-friction flow path that dramatically reduces maintenance costs and extends the equipment's service life.

The Core Advantage: Chemical Inertness and Purity

The primary reason engineers specify PTFE-lined valves is the unparalleled performance of the Polytetrafluoroethylene (PTFE) liner itself. It acts as a protective barrier, delivering two key benefits.

Unmatched Resistance to Aggressive Media

PTFE is one of the most chemically inert polymers available. This makes it exceptionally resistant to a vast range of corrosive chemicals, acids, and solvents.

By lining the valve's interior surfaces, the PTFE shield prevents the process fluid from ever contacting the metal body, eliminating the risk of corrosion and chemical attack on the valve's core structure.

Preventing Process Contamination

The non-stick, low-friction surface of PTFE is critical in high-purity applications, such as in the pharmaceutical or food and beverage industries.

Because the liner is non-reactive and prevents media from adhering to the valve walls, it ensures the purity of the process fluid is maintained. This eliminates the risk of contamination from either the valve's metal components or previous batches.

Driving Operational Efficiency and Reliability

Beyond chemical resistance, the design and material properties of these valves directly contribute to smoother, more reliable plant operations.

Superior Sealing and Leak Prevention

The design of a PTFE-lined butterfly valve ensures a tight, reliable seal when closed. This bubble-tight shut-off capability is crucial for process control and safety, preventing dangerous leaks and ensuring process isolation when needed.

Minimized Friction and Uninterrupted Flow

The famously low coefficient of friction of PTFE means media flows through the valve with minimal resistance. This "non-stick" property prevents sludges or other materials from building up inside the valve, ensuring consistent flow and reducing the energy required to operate the valve.

High Thermal Stability

PTFE maintains its integrity and performance across a wide range of temperatures. This thermal stability allows these valves to be used reliably in processes that involve both hot and cold media without degrading or compromising the seal.

Understanding the Financial Impact

While the initial purchase price is a factor, the true value of PTFE-lined valves becomes clear when you analyze the total cost of ownership over the equipment's lifespan.

Significant Reduction in Maintenance

Because the valve's internal metal parts are protected from the process media, wear and tear from corrosion and chemical erosion are virtually eliminated. This drastically reduces the need for frequent repairs, component replacements, and associated downtime.

Extended Service Life

The high durability of the PTFE lining combined with the protection it affords the valve body leads to a significantly longer operational lifespan compared to many unlined or alternative valve types in similar service.

Critical Considerations and Trade-offs

While highly effective, PTFE-lined valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Limitations

Although PTFE has good thermal stability, it does have upper temperature and pressure limits. Exceeding these specifications can cause the liner to deform or fail, compromising the seal.

Not Ideal for Abrasive Media

PTFE is a relatively soft material. It is not well-suited for services containing hard, abrasive particles (like heavy slurries), which can quickly erode the liner and lead to premature failure.

Proper Installation is Non-Negotiable

The integrity of the liner is paramount. It can be easily damaged during installation, particularly by over-torquing flange bolts, which can crack or deform the PTFE. Careful handling and adherence to installation procedures are essential.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its strengths to your primary operational goal.

- If your primary focus is handling highly corrosive or high-purity fluids: The chemical inertness and non-stick surface of a PTFE-lined valve make it an industry standard for ensuring both asset protection and process purity.

- If your primary focus is minimizing long-term operational costs: The combination of extended service life and dramatically reduced maintenance makes these valves a powerful choice for lowering the total cost of ownership.

- If your primary focus is process safety and reliability: The excellent, bubble-tight sealing capabilities prevent leaks of hazardous materials, making them a dependable component in critical applications where containment is essential.

Ultimately, choosing a PTFE-lined butterfly valve is an investment in long-term operational stability and efficiency.

Summary Table:

| Benefit | Key Feature | Impact |

|---|---|---|

| Chemical Resistance | PTFE liner acts as a barrier | Protects valve body from corrosion, ideal for acids and solvents |

| Process Purity | Non-stick, non-reactive surface | Prevents contamination in pharmaceutical and food & beverage applications |

| Operational Efficiency | Low friction, bubble-tight seal | Ensures consistent flow, reduces energy use, and prevents leaks |

| Cost-Effectiveness | Reduced maintenance and extended service life | Lowers total cost of ownership over the valve's lifespan |

Ready to enhance your process reliability with high-performance PTFE components?

KINTEK specializes in the precision manufacturing of PTFE components, including custom seals, liners, and labware. Our expertise is ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We deliver durable, contamination-free solutions that protect your equipment and ensure process purity, from prototype to high-volume production.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can improve your operational efficiency and reduce long-term costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems