Investing in high-quality PTFE rotary shaft lip seals is a strategic decision that delivers significant long-term value by enhancing equipment reliability and performance, especially in demanding operational conditions. These seals provide superior chemical resistance, function across an extreme temperature range, and dramatically reduce friction, leading to a longer service life and lower overall maintenance costs compared to traditional rubber seals.

The core benefit of PTFE seals lies in their ability to solve critical performance gaps where conventional elastomer seals fail. By excelling in high-speed, high-temperature, and chemically aggressive environments, they shift the focus from short-term component cost to long-term operational value and system uptime.

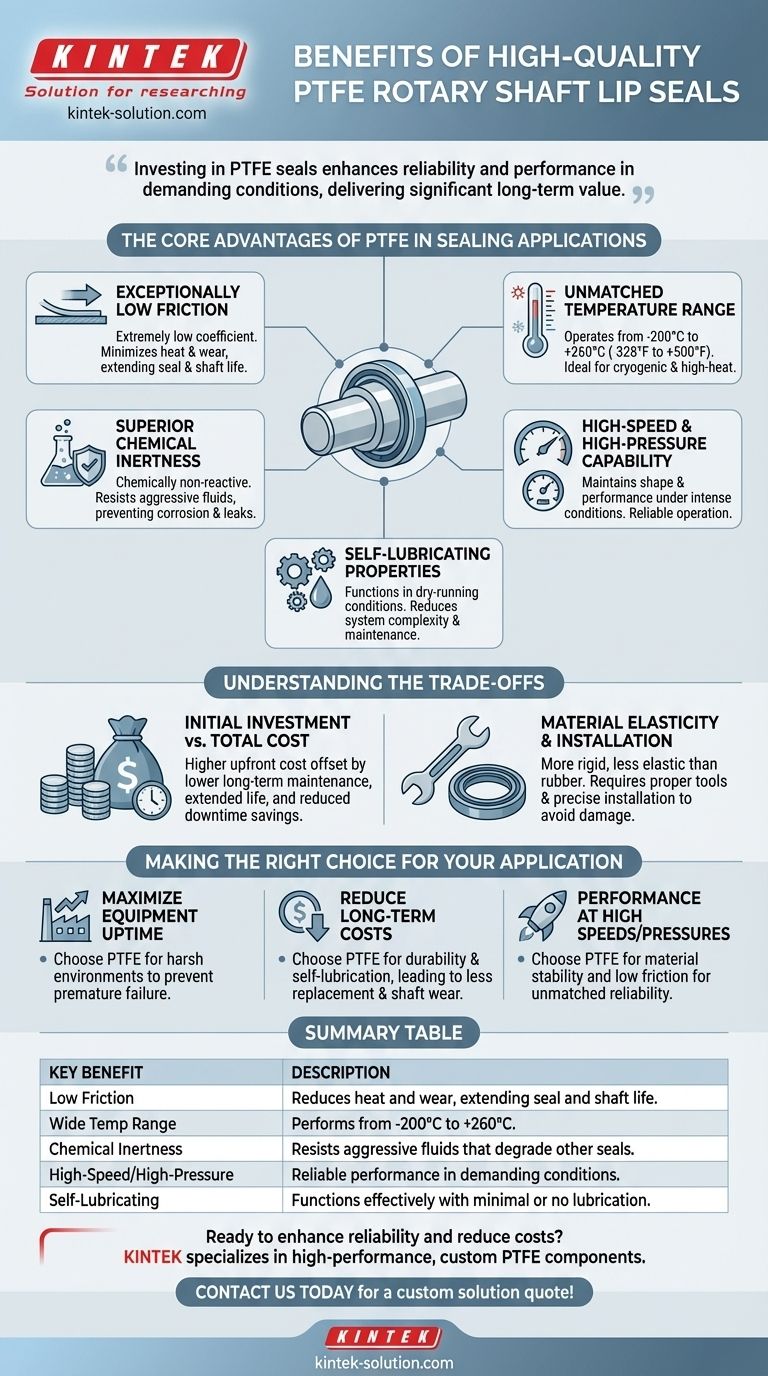

The Core Advantages of PTFE in Sealing Applications

To understand the value of PTFE seals, we must look at the unique properties of the material itself. Polytetrafluoroethylene (PTFE) offers a combination of characteristics that make it uniquely suited for challenging sealing tasks.

Exceptionally Low Friction

One of the most significant properties of PTFE is its extremely low coefficient of friction. This means it glides smoothly over mating surfaces like rotary shafts.

This low-friction nature minimizes heat generation during operation, even at high speeds. It also drastically reduces wear on both the seal lip and the shaft surface, extending the operational life of both components.

Unmatched Temperature Range

PTFE seals operate effectively across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes them the definitive choice for both cryogenic applications and high-heat environments where standard rubber or elastomer seals would become brittle or degrade rapidly.

Superior Chemical Inertness

PTFE is a non-reactive material, making it chemically inert to most industrial chemicals and aggressive fluids.

This property ensures the seal maintains its integrity and sealing capability when exposed to corrosive media that would quickly destroy other materials, preventing costly leaks and equipment failure.

High-Speed and High-Pressure Capability

The inherent strength and low-friction properties of PTFE allow these seals to perform reliably in high-speed and high-pressure applications.

Where traditional seals might extrude or wear out prematurely under intense conditions, PTFE maintains its shape and effectiveness, ensuring consistent performance.

Self-Lubricating Properties

PTFE seals are self-lubricating, meaning they can function effectively in dry-running or minimally lubricated conditions.

This reduces system complexity and is a critical advantage in applications where external lubrication is impractical or undesirable, such as in food processing or aerospace systems.

Understanding the Trade-offs

While the performance benefits are clear, a balanced analysis requires acknowledging the trade-offs. Being aware of these factors ensures you are making a fully informed decision.

Initial Investment vs. Total Cost of Ownership

The primary trade-off is the higher initial purchase price of PTFE seals compared to standard elastomer seals.

However, this upfront cost is often offset by a significantly lower total cost of ownership. The extended lifespan, reduced shaft wear, and decreased maintenance downtime frequently result in substantial long-term savings.

Material Elasticity and Installation

PTFE is a more rigid material than rubber. It has less "memory" and elasticity, which can make installation more sensitive.

Proper installation tools and procedures are critical to avoid damaging the seal lip. Unlike a flexible rubber seal, a PTFE seal is less forgiving of shaft imperfections or installation errors.

Making the Right Choice for Your Application

Choosing the correct seal material is not just a component choice; it's a decision about your equipment's long-term health and performance.

- If your primary focus is maximizing equipment uptime in harsh environments: PTFE is the superior choice due to its chemical and thermal resistance, preventing premature seal failure.

- If your primary focus is reducing long-term maintenance and operational costs: The durability and self-lubricating nature of PTFE seals lead to less frequent replacement and reduced wear on expensive shafts.

- If your primary focus is performance at high speeds or pressures: PTFE's material stability and low-friction characteristics provide the reliability that standard seals cannot match.

Ultimately, selecting a high-quality PTFE seal is an investment in the resilience and efficiency of your most critical machinery.

Summary Table:

| Key Benefit | Description |

|---|---|

| Low Friction | Reduces heat and wear, extending seal and shaft life. |

| Wide Temp Range | Performs from -200°C to +260°C (-328°F to +500°F). |

| Chemical Inertness | Resists aggressive fluids that degrade other seals. |

| High-Speed/High-Pressure | Reliable performance in demanding conditions. |

| Self-Lubricating | Functions effectively with minimal or no lubrication. |

Ready to enhance your equipment's reliability and reduce long-term costs?

KINTEK specializes in manufacturing high-performance, custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates at peak performance in the most demanding environments.

Contact us today to discuss your specific application and receive a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability