In the medical field, Polytetrafluoroethylene (PTFE) is a critical material used for a range of life-saving applications, most notably in cardiovascular grafts, surgical patches, and as low-friction components in medical instruments. Its value stems from a unique combination of biological inertness, chemical resistance, and an exceptionally slippery surface, allowing it to function safely and reliably both inside the human body and in sterile clinical environments.

PTFE's success in medicine is not due to a single property, but its rare synthesis of being almost completely ignored by the body's immune system while offering high-performance physical characteristics that engineers can leverage for complex medical devices.

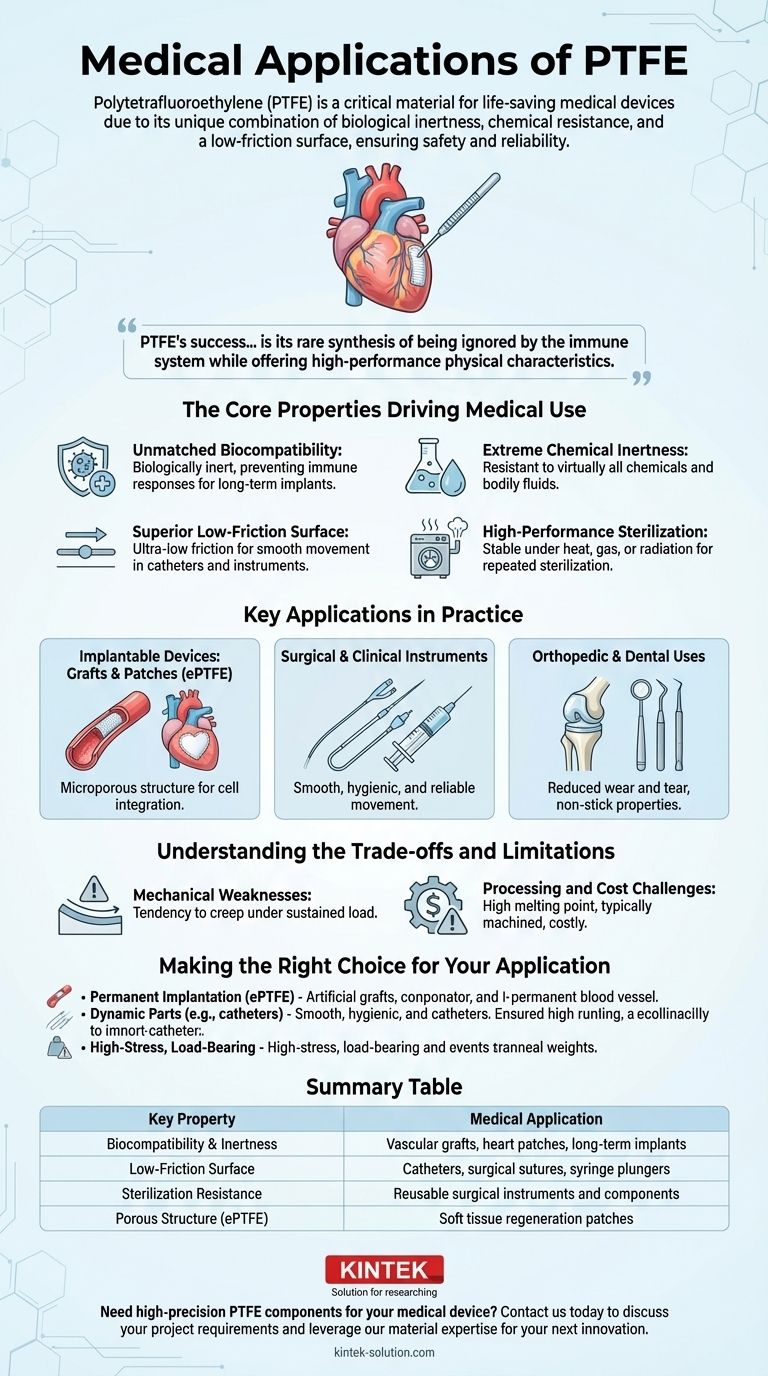

The Core Properties Driving Medical Use

The suitability of PTFE for medical applications is rooted in a few fundamental material properties that are difficult to find in a single polymer. These characteristics make it a trusted choice for devices where failure is not an option.

Unmatched Biocompatibility

PTFE is biologically inert, meaning the human body does not recognize it as a foreign substance. This prevents immune responses, rejection, and other adverse physiological side effects, making it an ideal material for long-term implants.

Extreme Chemical Inertness

The material is highly resistant to virtually all chemicals and solvents. This ensures that it will not degrade when exposed to bodily fluids or the aggressive chemicals used in sterilization processes.

Superior Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality. This is critical for applications like catheters that must slide through tissues with minimal damage, or for instrument parts that require smooth, frictionless movement.

High-Performance Sterilization

Medical devices must be sterile. PTFE's high thermal stability and chemical resistance mean it can be sterilized by any common method—including autoclaving (steam), ethylene oxide (EtO), or gamma radiation—without losing its integrity.

Key Applications in Practice

These core properties translate directly into specific, high-stakes medical uses where PTFE has become an industry standard.

Implantable Devices: Grafts and Patches

Perhaps its most famous medical use is in expanded PTFE (ePTFE). This form has a multi-microporous structure that is ideal for creating artificial blood vessels (vascular grafts), heart patches, and patches for soft tissue regeneration. The porous nature allows the body's own cells to grow into the material, integrating it over time.

Surgical and Clinical Instruments

The low-friction property is leveraged in many devices. PTFE is used in catheters, surgical sutures, syringe plungers, and seals for medical pumps. In each case, it ensures smooth, hygienic, and reliable mechanical movement.

Orthopedic and Dental Uses

Due to its biocompatibility and low-friction surface, PTFE is also used as a component in some artificial joints to reduce wear and tear between moving parts. Its non-stick properties also provide benefits in specialized dental applications.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. Its limitations are as important to understand as its strengths.

Mechanical Weaknesses

The primary drawback of PTFE is its tendency to creep and cold flow. This means the material can slowly deform over time when under a sustained mechanical load. This property makes it unsuitable for high-load, structural applications unless it is reinforced with other materials.

Processing and Cost Challenges

PTFE has a very high melting temperature and cannot be processed using conventional methods like injection molding. It is typically machined from solid blocks or rods, which is a more expensive and slower manufacturing process, making individual components costly.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on leveraging its unique strengths while respecting its limitations. The ideal application matches the material's properties to a specific medical need.

- If your primary focus is permanent implantation (e.g., vascular grafts): PTFE's elite biocompatibility and the porous structure of its expanded form (ePTFE) make it one of the best materials available.

- If your primary focus is dynamic or moving parts (e.g., catheters): Its exceptionally low friction is the defining characteristic, ensuring smooth and safe operation.

- If your primary focus is high-stress, load-bearing components: You must proceed with caution, as its tendency to creep makes it a poor choice without structural reinforcement.

Ultimately, PTFE remains an indispensable high-performance polymer in medicine, solving critical challenges that few other materials can address.

Summary Table:

| Key Property | Medical Application |

|---|---|

| Biocompatibility & Inertness | Vascular grafts, heart patches, long-term implants |

| Low-Friction Surface | Catheters, surgical sutures, syringe plungers |

| Sterilization Resistance | Reusable surgical instruments and components |

| Porous Structure (ePTFE) | Soft tissue regeneration patches |

Need high-precision PTFE components for your medical device?

At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and complex components for the medical, semiconductor, and laboratory industries. Our expertise in precision production ensures your devices meet the highest standards for biocompatibility and performance, from prototypes to high-volume orders.

Contact us today to discuss your project requirements and leverage our material expertise for your next innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications