In short, Teflon (PTFE) rods are chosen for industrial applications due to their unique combination of three core properties: extreme chemical inertness, a very wide operational temperature range, and an exceptionally low coefficient of friction. This makes them one of the most versatile and reliable materials for creating components that must survive harsh chemical, thermal, and mechanical environments where other materials would quickly fail.

The true value of Teflon in an industrial setting isn't just one of its properties, but its ability to deliver all of them simultaneously. It solves the complex problem of needing a material that is simultaneously non-reactive, stable at extreme temperatures, and naturally self-lubricating.

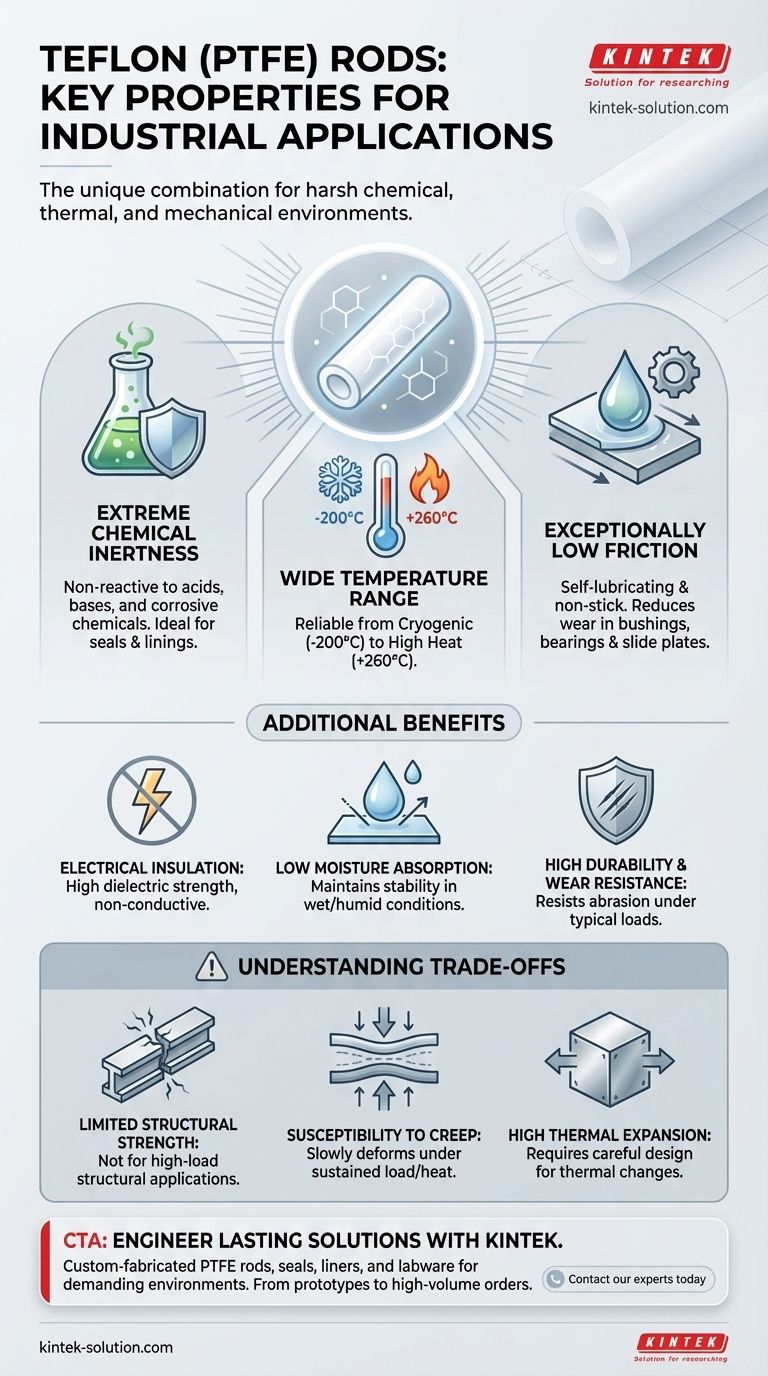

Unmatched Resilience in Harsh Environments

The primary reason engineers specify Teflon is its ability to withstand conditions that would degrade or destroy most other plastics and even some metals. This resilience stems from its fundamental chemical and thermal stability.

Extreme Chemical Inertness

Teflon’s chemical structure makes it non-reactive to nearly all industrial chemicals, acids, and bases. This property is critical for applications involving corrosive materials.

Unlike metals that can corrode or other plastics that can swell or dissolve, Teflon remains physically and chemically unchanged, making it ideal for seals, gaskets, and linings in chemical processing equipment.

Broad Thermal Stability

Teflon rods perform reliably across an exceptionally wide temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This allows the material to be used in everything from cryogenic applications to high-temperature processing without losing its structural integrity or key properties.

Resistance to Environmental Factors

Beyond controlled industrial settings, Teflon exhibits excellent resistance to environmental degradation. It is highly resistant to weathering, UV radiation, and oxidation.

Furthermore, it has a very low moisture absorption rate, ensuring its properties remain stable even in wet or high-humidity environments. This makes it a durable choice for outdoor or exposed components.

Superior Mechanical and Electrical Performance

While not a high-strength structural material, Teflon’s mechanical properties are perfectly suited for components designed to reduce friction, prevent wear, and provide insulation.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, giving it its famous "non-stick" or self-lubricating quality.

In industrial machinery, this property is invaluable for creating bushings, bearings, and slide plates that reduce energy consumption and wear on moving parts without requiring external lubricants.

High Durability and Wear Resistance

Despite being a relatively soft material, Teflon is extremely durable and resistant to frictional wear, abrasion, and deformation under typical loads.

This resilience ensures a long service life for components, reducing maintenance costs and operational downtime, especially in applications with constant motion or vibration.

Excellent Electrical Insulation

Teflon is an outstanding electrical insulator with high dielectric strength. It does not conduct electricity, making it a perfect material for insulators, spacers, and connectors in electrical and electronic equipment, particularly in high-frequency applications.

Understanding the Trade-offs of Teflon (PTFE)

No material is perfect, and being an effective advisor means acknowledging limitations. While Teflon's properties are remarkable, they come with trade-offs that are critical to consider during the design phase.

Limited Structural Strength

Teflon is not intended for high-load structural applications. It has a relatively low tensile strength and stiffness compared to other engineering plastics like PEEK or nylon. It excels as a surface, seal, or bearing, not as a primary structural frame.

Susceptibility to Creep

Under a sustained compressive load, especially at elevated temperatures, Teflon can be subject to "creep" or "cold flow." This means it may slowly deform over time, which must be accounted for in the design of critical seals and gaskets.

High Coefficient of Thermal Expansion

While stable across a wide temperature range, Teflon expands and contracts significantly more than metals with temperature changes. Engineers must design parts with appropriate tolerances to accommodate this thermal expansion and prevent component failure.

Making the Right Choice for Your Application

Selecting the right material requires matching its strengths to your primary goal. Use Teflon rods when your component’s success depends on its unique combination of properties.

- If your primary focus is handling corrosive materials: Teflon's chemical inertness makes it the default choice for seals, linings, and components in chemical processing.

- If your primary focus is reducing friction: Its self-lubricating nature is ideal for creating low-wear bushings, bearings, and slide plates that operate without traditional lubricants.

- If your primary focus is performance in extreme temperatures: Teflon's broad thermal stability ensures reliability in both cryogenic and high-heat environments.

- If your primary focus is electrical insulation: Its high dielectric strength makes it a superior material for insulators and components in sensitive electronic assemblies.

By understanding both its powerful advantages and its specific limitations, you can leverage Teflon to engineer highly reliable and long-lasting industrial solutions.

Summary Table:

| Key Property | Why It Matters for Industrial Applications |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and bases, ideal for seals and linings in corrosive environments. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C, suitable for cryogenic to high-heat processes. |

| Low Coefficient of Friction | Self-lubricating; reduces wear in bushings, bearings, and slide plates without external lubricants. |

| Excellent Electrical Insulation | High dielectric strength; perfect for insulators and connectors in electrical/electronic equipment. |

| Low Moisture Absorption | Maintains stability in wet/humid conditions, ensuring long-term durability. |

Engineer lasting solutions with precision-made Teflon components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE rods, seals, liners, and labware are engineered to thrive in your most demanding environments. We deliver the unique combination of chemical inertness, thermal stability, and low friction you need—from prototypes to high-volume orders.

Ready to enhance your application's reliability? Contact our experts today to discuss your specific requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability