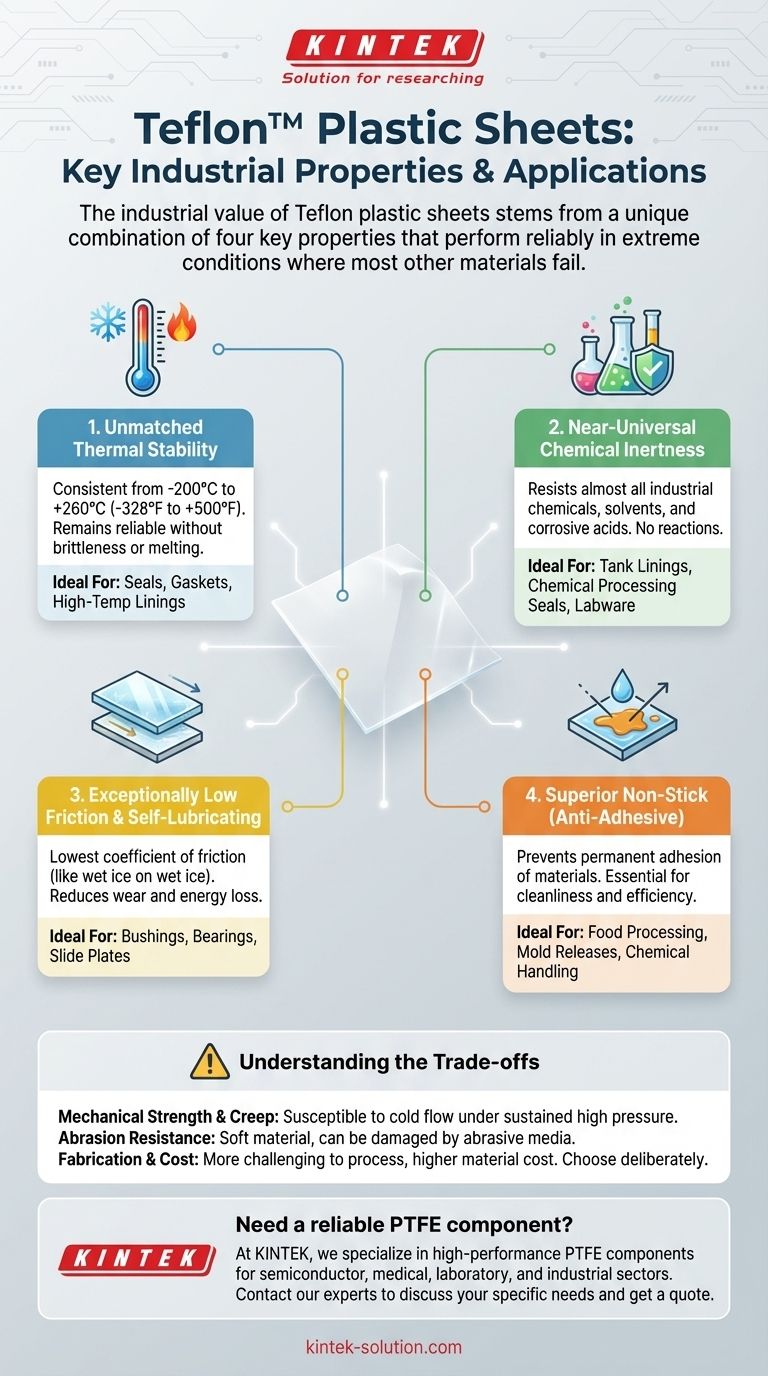

The industrial value of Teflon plastic sheets stems from a unique combination of four key properties that allow them to perform reliably in extreme conditions where most other materials fail. These are its exceptional thermal stability across a vast temperature range, its near-universal chemical inertness, an extremely low coefficient of friction, and superior non-stick, or anti-adhesive, capabilities.

Teflon's suitability isn't about excelling in a single area; it's about the powerful synergy of its core properties. It simultaneously solves problems of extreme heat, corrosive chemicals, and mechanical friction, making it a definitive material for high-stakes industrial challenges.

The Pillars of Teflon's Industrial Performance

To understand why Teflon (PTFE) is a cornerstone material in sectors from aerospace to food production, we must examine how its fundamental characteristics translate into practical benefits. Each property addresses a specific set of industrial failure points.

Unmatched Thermal Stability

Teflon maintains its structural integrity and performance characteristics across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This makes it one of the most thermally-stable plastics available. Unlike other polymers that may become brittle in cryogenic conditions or melt at high temperatures, Teflon remains consistent and reliable.

Near-Universal Chemical Inertness

PTFE is renowned for its resistance to almost all industrial chemicals, solvents, and corrosive acids. Its molecular structure is incredibly stable, preventing chemical reactions with substances it contacts.

This inertness is critical for applications like gaskets, seals, and tank linings in chemical processing plants. It ensures equipment longevity and prevents contamination of the materials being processed.

Exceptionally Low Friction

Teflon exhibits one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This property also makes it inherently self-lubricating.

In industrial settings, this translates directly to reduced wear and energy loss in moving parts. It is the ideal material for bushings, bearings, and slide plates where smooth, consistent motion is required without external lubricants.

Superior Non-Stick Surface

The famous "non-stick" quality is technically known as an anti-adhesive property. Very few substances will permanently adhere to a Teflon surface.

This is invaluable in applications like food processing equipment, mold releases, and chemical handling, where preventing material buildup is essential for operational efficiency, hygiene, and consistent output.

Understanding the Trade-offs

No material is perfect for every situation. While Teflon's properties are exceptional, a technical advisor must also highlight its limitations to ensure it is specified correctly.

Mechanical Strength and Creep

While durable, PTFE is a relatively soft material compared to engineering plastics like PEEK or metals. Under sustained high pressure or load, it can be susceptible to "creep" or cold flow, causing it to deform over time.

Abrasion Resistance

Teflon's low friction provides excellent resistance to frictional wear. However, its softness means it can be damaged by abrasive media, such as hard particles or slurries. In such cases, filled grades of PTFE may be a more suitable choice.

Fabrication and Cost

Compared to common polymers, PTFE can be more challenging to process and machine. Its higher material cost means it is typically specified for applications where its unique performance characteristics are a strict requirement, not a general-purpose choice.

Making the Right Choice for Your Application

Selecting Teflon should be a deliberate decision based on the primary challenge you need to solve.

- If your primary focus is reliability in extreme temperatures or corrosive environments: Teflon is an industry-standard choice for seals, gaskets, and linings that cannot fail.

- If your primary focus is reducing friction in moving parts: Its self-lubricating nature makes it ideal for low-to-moderate load bearings, bushings, and slide plates.

- If your primary focus is preventing material buildup or ensuring clean surfaces: Its non-stick property is unmatched for applications in food, pharmaceutical, and chemical manufacturing.

- If your primary focus is high-frequency electrical insulation: Its excellent dielectric properties make it a top-tier material for specialized electronics and aerospace components.

By understanding these core properties and their inherent trade-offs, you can confidently specify Teflon for the demanding applications where its performance is truly non-negotiable.

Summary Table:

| Key Property | Industrial Benefit | Ideal For |

|---|---|---|

| Thermal Stability (-200°C to +260°C) | Reliability in extreme heat/cold | Seals, gaskets, high-temp linings |

| Chemical Inertness | Resists almost all chemicals | Tank linings, chemical processing seals |

| Low Friction / Self-Lubricating | Reduces wear and energy loss | Bushings, bearings, slide plates |

| Superior Non-Stick | Prevents material buildup | Food processing, mold releases |

Need a reliable PTFE component for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from custom seals and liners to labware and complex fabricated parts. Our expertise ensures precision and durability for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require prototypes or high-volume orders, we deliver solutions that leverage Teflon's unique properties to solve your toughest challenges.

Contact our experts today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability