The defining properties of PTFE for sanitary gaskets are its exceptional chemical inertness, high-temperature tolerance, and non-stick surface. These characteristics ensure the material will not react with food or drug products, withstand rigorous sterilization processes, and prevent the buildup of contaminants, directly supporting product purity and safety.

The core reason PTFE is trusted in sanitary applications is its dual nature: it is chemically invisible to the product and physically resilient to the harsh processing environment. This combination makes it a stable, non-contaminating barrier that preserves product integrity.

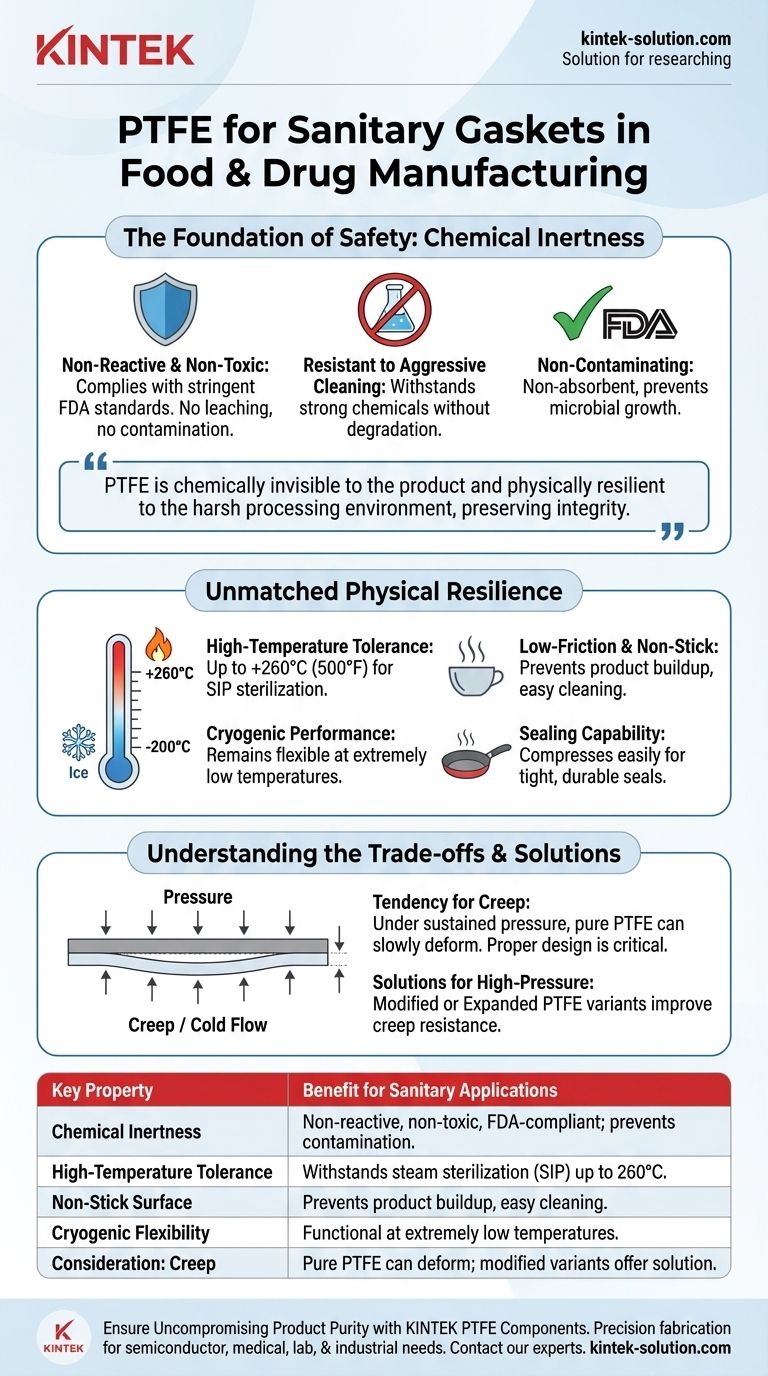

The Foundation of Safety: Chemical Inertness

In food, beverage, and pharmaceutical manufacturing, the gasket material must not interact with the product in any way. PTFE's chemical composition makes it one of the most inert materials available.

### Non-Reactive and Non-Toxic

PTFE is biologically inert and non-toxic, which is why it complies with stringent FDA standards for food-contact materials.

It does not react with, leach into, or contaminate the product passing through the line, ensuring the final product's purity, taste, and safety are preserved.

### Resistance to Aggressive Cleaning Agents

Sanitary systems undergo frequent and aggressive cleaning and sterilization cycles using strong chemicals.

PTFE's broad chemical resistance means it will not degrade when exposed to these sanitizing agents, ensuring a long and reliable service life without compromising the seal.

### Non-Contaminating Properties

The material is non-absorbent, meaning it does not trap water or product particles that could harbor microbial growth.

Furthermore, PTFE is non-wetting, non-corrosive, and odorless, preventing it from adding any unwanted properties to the materials it contacts.

Unmatched Physical Resilience

Beyond its chemical stability, a sanitary gasket must maintain its physical integrity under a wide range of operational stresses, from high heat to mechanical pressure.

### High-Temperature Tolerance

PTFE gaskets can operate effectively at continuous service temperatures up to +260°C (500°F).

This makes them ideal for systems that use high-heat processes or undergo steam-in-place (SIP) sterilization, which is a common requirement in sanitary environments.

### Performance at Cryogenic Temperatures

The material also remains flexible and functional at extremely low, or cryogenic, temperatures. This versatility allows it to be used in processes involving flash-freezing or the transport of chilled products.

### Low-Friction and Non-Stick Surface

One of PTFE's most famous properties is its extremely low coefficient of friction, making its surface non-stick.

In a sanitary gasket, this prevents product buildup on the gasket surface. This quality is critical for hygiene, as it minimizes the potential for biofilm formation and makes cleaning processes far more effective.

### Sealing Capability and Durability

PTFE is flexible and can compress easily to create a tight, effective seal, preventing leaks that could lead to product loss or contamination. This durability ensures a long-lasting seal even in harsh processing conditions.

Understanding the Trade-offs of PTFE

While PTFE's properties are overwhelmingly positive for sanitary applications, no material is without its limitations. Being aware of these is key to proper implementation.

### Tendency for Creep or "Cold Flow"

The same flexibility that allows PTFE to form a good seal can also be a drawback. Under sustained pressure and temperature, pure (virgin) PTFE can slowly deform over time, a phenomenon known as creep or cold flow.

This deformation can eventually lead to a loss of sealing pressure and potential leaks. Proper flange design and torque procedures are critical to manage this.

### Solutions for High-Pressure Applications

For applications involving very high pressures or temperatures where creep is a significant concern, standard PTFE may not be the optimal choice.

In these scenarios, modified or expanded PTFE gaskets are often used. These variations incorporate other materials or structures to improve creep resistance while retaining PTFE's core benefits of chemical inertness and temperature tolerance.

Making the Right Choice for Your Process

Your specific operational needs will determine if PTFE is the right fit and which type is most appropriate.

- If your primary focus is product purity and compliance: PTFE is an industry standard due to its inertness and FDA-compliant status.

- If your primary focus is processes with extreme temperatures: The material's wide operating range, from cryogenic lows to steam-sterilization highs, makes it a reliable choice.

- If your primary focus is preventing contamination and ensuring cleanability: PTFE's non-stick surface provides a significant advantage in minimizing material buildup and simplifying sanitation.

- If your primary focus is high-pressure sealing integrity: You should evaluate modified or expanded PTFE variants to mitigate the risk of cold flow.

Ultimately, choosing PTFE is a decision to prioritize unwavering material stability in the most demanding sanitary environments.

Summary Table:

| Key Property | Benefit for Sanitary Applications |

|---|---|

| Chemical Inertness | Non-reactive, non-toxic, and FDA-compliant; prevents product contamination. |

| High-Temperature Tolerance | Withstands steam sterilization (SIP) up to 260°C (500°F). |

| Non-Stick Surface | Prevents product buildup and biofilm formation for easy cleaning. |

| Cryogenic Flexibility | Remains functional at extremely low temperatures for chilled processes. |

| Consideration: Creep | Pure PTFE can deform under pressure; modified PTFE variants offer a solution. |

Ensure Uncompromising Product Purity with KINTEK PTFE Components

For semiconductor, medical, laboratory, and industrial manufacturers, the stability of your components is non-negotiable. KINTEK specializes in precision PTFE fabrication—from custom prototypes to high-volume orders—delivering the chemical inertness and thermal resilience your sanitary processes demand.

Let us provide the reliable seals, liners, and labware that protect your product integrity. Contact our experts today to discuss your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications