At its core, Polytetrafluoroethylene (PTFE) is a high-performance polymer defined by four key properties: extreme chemical inertness, a vast operational temperature range, an exceptionally low coefficient of friction, and superior electrical insulation. These characteristics make PTFE sheets a foundational material for solving engineering challenges in harsh and demanding environments where conventional plastics would fail.

The true value of PTFE lies not in a single property, but in its unique combination of thermal stability, chemical resistance, and non-stick performance. Understanding this synergy—along with its mechanical limitations—is the key to deploying it effectively.

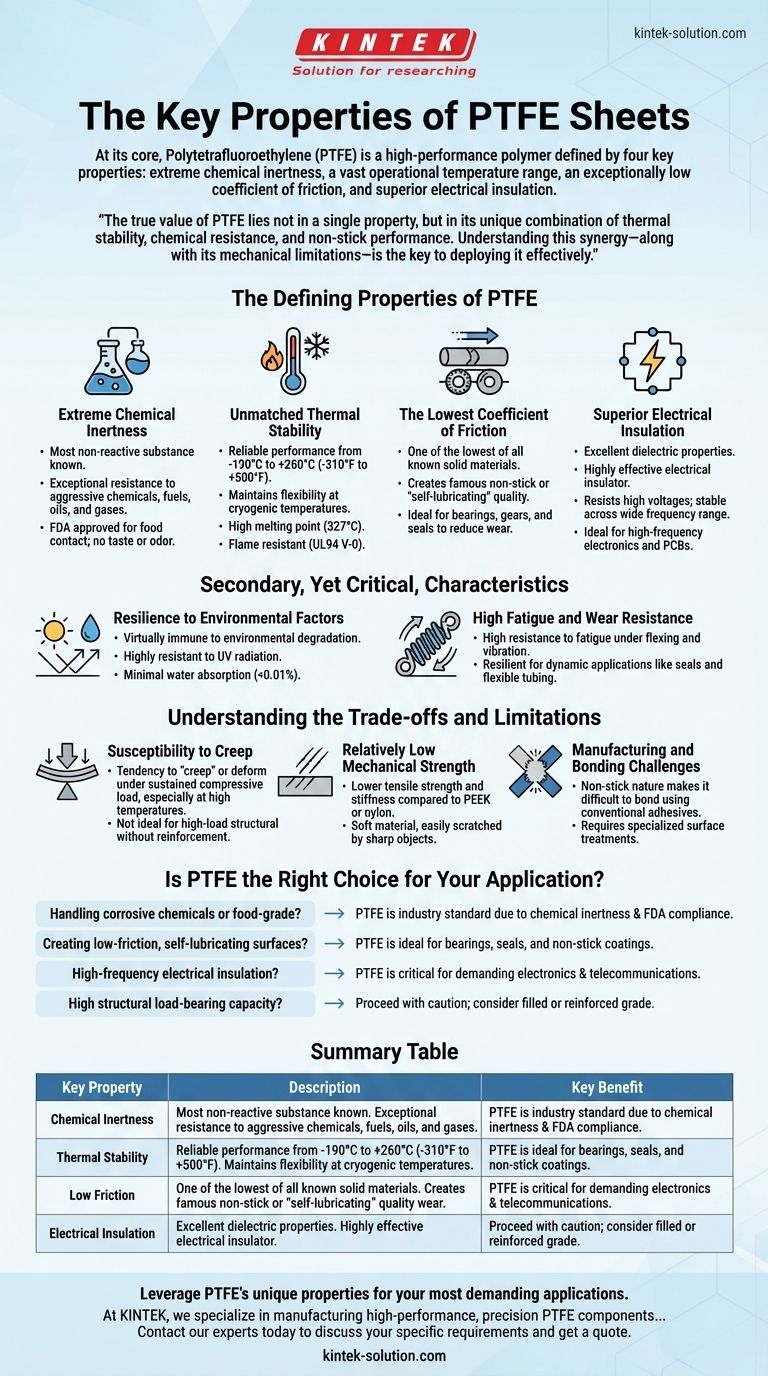

The Defining Properties of PTFE

PTFE's reputation as a "problem-solver" material stems from a few core characteristics that set it apart from nearly all other polymers.

Extreme Chemical Inertness

PTFE is one of the most non-reactive substances known. It offers exceptional resistance to a wide array of aggressive chemicals, fuels, oils, and gases.

This chemical stability is why PTFE is often used as a protective lining or in components that handle corrosive materials. It is also FDA approved for food contact applications, as it does not impart taste, odor, or contaminants.

Unmatched Thermal Stability

PTFE sheets perform reliably across an incredibly broad temperature spectrum, typically from -190°C to +260°C (-310°F to +500°F).

It maintains its flexibility even at cryogenic temperatures and has a high melting point of 327°C (621°F). Furthermore, PTFE is highly flame resistant, often carrying a UL94 V-0 rating, meaning it self-extinguishes within seconds without dripping.

The Lowest Coefficient of Friction

Of all known solid materials, PTFE has one of the lowest coefficients of friction. This creates its famous non-stick or "self-lubricating" quality.

This property is invaluable for applications like bearings, gears, and seals where reducing wear and eliminating the need for liquid lubricants is critical.

Superior Electrical Insulation

PTFE possesses excellent dielectric properties, meaning it is a highly effective electrical insulator. It resists high voltages and is stable across a wide range of frequencies.

This makes it an ideal material for high-frequency electronics, such as insulators in coaxial cables, connectors, and printed circuit boards (PCBs).

Secondary, Yet Critical, Characteristics

Beyond the four primary properties, several other features contribute to PTFE's versatility and performance.

Resilience to Environmental Factors

PTFE is virtually immune to environmental degradation. It is highly resistant to UV radiation and does not age or become brittle with sun exposure.

Additionally, its water absorption is minimal (less than 0.01%), ensuring that its properties remain stable even in humid or submerged conditions.

High Fatigue and Wear Resistance

Despite its soft feel, PTFE exhibits high resistance to fatigue under flexing and vibration. This durability is often demonstrated by its performance on a Wöhler curve, which measures a material's fatigue life.

This resilience makes it suitable for dynamic applications like seals and flexible tubing that must withstand repeated movement.

Understanding the Trade-offs and Limitations

No material is perfect. To be a trusted advisor is to acknowledge a material's weaknesses. The key to successfully using PTFE is to design around its limitations.

Susceptibility to Creep

The most significant limitation of PTFE is its tendency to "creep" or deform over time when subjected to a sustained compressive load, especially at elevated temperatures.

This means pure PTFE is generally not suitable for high-load structural applications without reinforcement (e.g., glass or carbon fibers).

Relatively Low Mechanical Strength

Compared to engineering plastics like PEEK or nylon, PTFE has relatively low tensile strength and stiffness. It is a soft material that can be easily scratched or damaged by sharp objects.

Designers must account for this by ensuring components are not subjected to high tensile or abrasive forces that exceed the material's capacity.

Manufacturing and Bonding Challenges

PTFE's non-stick nature makes it extremely difficult to bond to other materials using conventional adhesives. Specialized surface treatments like chemical etching are required to achieve a reliable bond.

Is PTFE the Right Choice for Your Application?

Your choice of material should always be driven by the primary demands of your project.

- If your primary focus is handling corrosive chemicals or food-grade materials: PTFE is an industry standard due to its chemical inertness and FDA compliance.

- If your primary focus is creating low-friction, self-lubricating surfaces: PTFE's exceptionally low coefficient of friction makes it an ideal choice for bearings, seals, and non-stick coatings.

- If your primary focus is high-frequency electrical insulation: PTFE's excellent dielectric properties are critical for performance in demanding electronics and telecommunications hardware.

- If your primary focus is high structural load-bearing capacity: You must proceed with caution and consider a filled or reinforced grade of PTFE to mitigate its natural tendency to creep under pressure.

By understanding both its unparalleled strengths and its distinct limitations, you can leverage PTFE to solve your most demanding engineering challenges.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Exceptional resistance to corrosive chemicals, fuels, and oils. | Ideal for harsh chemical environments and FDA-compliant food contact. |

| Thermal Stability | Operates from -190°C to +260°C; flame resistant (UL94 V-0). | Reliable performance in extreme heat, cold, and fire-risk scenarios. |

| Low Friction | One of the lowest coefficients of friction of any solid material. | Self-lubricating for bearings, seals, and non-stick surfaces. |

| Electrical Insulation | Excellent dielectric properties across a wide frequency range. | Critical for high-frequency electronics, cables, and PCBs. |

Leverage PTFE's unique properties for your most demanding applications.

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components are engineered to excel in harsh environments.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications