At its core, PTFE's effectiveness as a gasket material stems from a unique combination of three elite properties: near-total chemical inertness, an exceptionally wide operating temperature range, and an extremely low coefficient of friction. This makes it a premier choice for sealing applications in harsh and demanding industrial environments where lesser materials would quickly degrade and fail.

PTFE is the default sealing solution for extreme environments. Its value comes from its ability to resist chemical attack and temperature swings that would destroy other materials, but this performance must be weighed against its inherent mechanical rigidity.

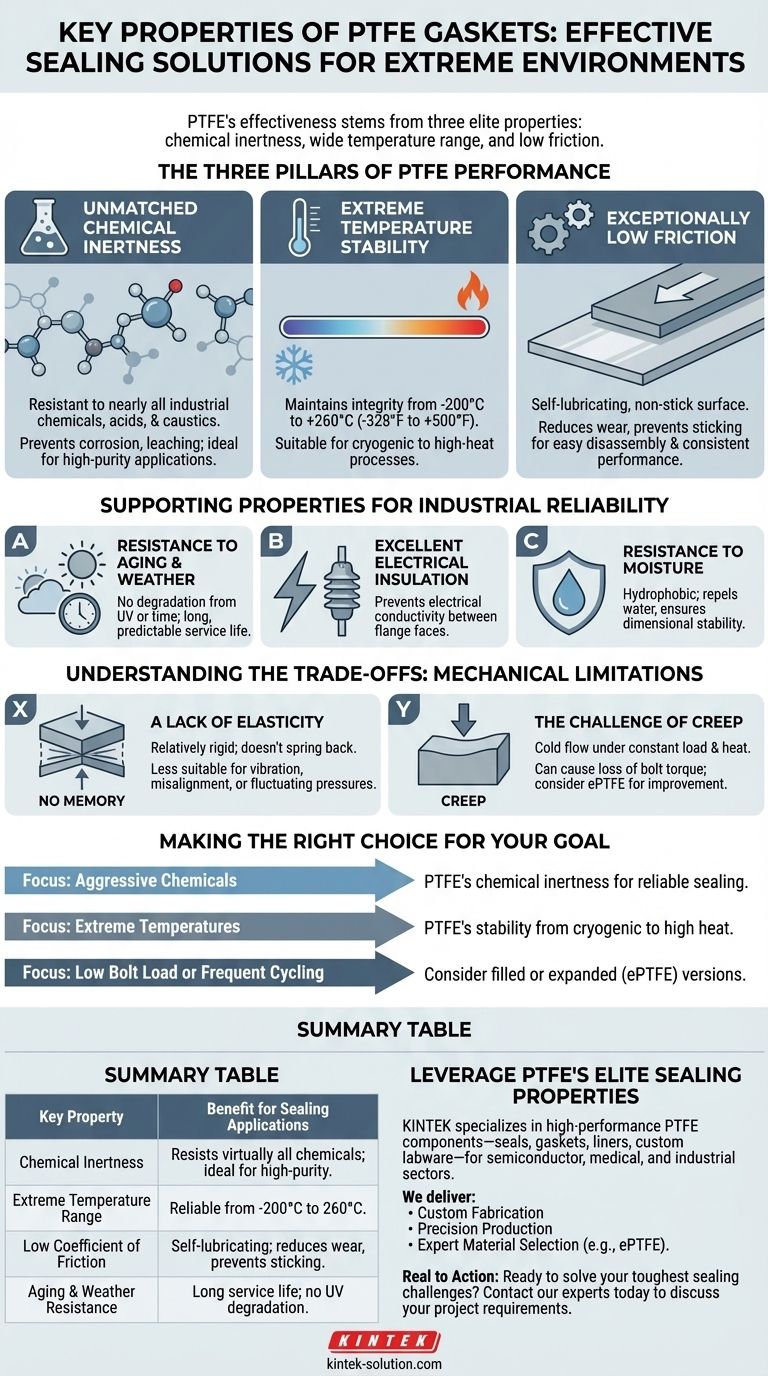

The Three Pillars of PTFE Performance

The primary reasons engineers specify PTFE (polytetrafluoroethylene) gaskets can be distilled down to three foundational characteristics.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and caustics. This inert nature prevents the gasket from corroding, dissolving, or reacting with the media it is sealing.

This property is also critical for high-purity applications, such as in the pharmaceutical or food and beverage industries. Because PTFE is inert, it does not leach contaminants or impart any taste or odor, ensuring the purity of the process fluid.

Extreme Temperature Stability

PTFE gaskets maintain their integrity and sealing capability across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes it one of the few materials suitable for both cryogenic applications and high-temperature industrial processes, providing a single, reliable solution for systems with significant temperature fluctuations.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "self-lubricating" or non-stick quality.

This characteristic is beneficial for reducing wear and tear in dynamic applications and prevents materials from sticking to the gasket surface. This ensures easy disassembly of flanged joints and consistent performance over time.

Supporting Properties for Industrial Reliability

Beyond the primary three, other characteristics contribute to PTFE's reputation as a durable and versatile sealing material.

Resistance to Aging and Weather

Unlike many elastomers, PTFE does not degrade with exposure to time, UV light, or weather. This non-aging quality ensures a long and predictable service life without embrittlement or loss of performance.

Excellent Electrical Insulation

PTFE is an excellent electrical insulator, a property that makes it invaluable for applications where gaskets must also prevent electrical conductivity between flange faces.

Resistance to Moisture

The material is inherently hydrophobic, meaning it repels water and does not absorb moisture. This ensures its dimensional stability and properties are not affected by humid or wet operating conditions.

Understanding the Trade-offs: The Mechanical Limitations

No material is perfect, and an objective assessment of PTFE requires acknowledging its primary weakness.

A Lack of Elasticity

The most significant limitation of pure PTFE is its lack of "memory" or elasticity. Unlike rubber or other elastomers, it is a relatively rigid material.

When compressed, it does not readily spring back to its original shape. This makes it less suitable for applications with significant vibration, flange misalignment, or fluctuating pressures where the gasket must constantly adapt to maintain a seal.

The Challenge of Creep

This rigidity contributes to a phenomenon known as creep, or cold flow. Under a constant compressive load, especially at elevated temperatures, PTFE can slowly deform over time.

This can lead to a loss of bolt torque and sealing pressure. This is why modified versions, such as expanded PTFE (ePTFE) or gaskets filled with other materials, were developed to improve creep resistance and mechanical stability.

Making the Right Choice for Your Goal

Choosing the right gasket means matching the material's properties to your primary operational challenge.

- If your primary focus is aggressive chemicals: PTFE's unparalleled chemical inertness provides the most reliable and long-lasting seal against corrosion.

- If your primary focus is extreme temperatures: Its stability from cryogenic lows to high industrial heat makes it a uniquely versatile and dependable choice.

- If your primary focus is low bolt load or frequent cycling: Be mindful of pure PTFE's rigidity and consider filled or expanded (ePTFE) versions for improved mechanical performance and sealability.

Ultimately, understanding these core properties allows you to leverage PTFE's strengths while mitigating its limitations for a truly effective sealing solution.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and caustics; ideal for high-purity processes. |

| Extreme Temperature Range | Performs reliably from cryogenic (-200°C) to high heat (260°C). |

| Low Coefficient of Friction | Self-lubricating; reduces wear and prevents sticking for easy maintenance. |

| Aging & Weather Resistance | Does not degrade with UV exposure or over time, ensuring long service life. |

Leverage PTFE's Elite Sealing Properties for Your Application

PTFE gaskets are the definitive solution for extreme environments, but their performance hinges on precision manufacturing. KINTEK specializes in fabricating high-performance PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver the reliability you need:

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

- Precision Production: Ensuring optimal performance and longevity for your critical applications.

- Expert Material Selection: Guidance on choosing the right PTFE formulation (including filled or expanded ePTFE) to overcome mechanical limitations like creep.

Ready to solve your toughest sealing challenges? Contact our experts today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support