In essence, PFA (Perfluoroalkoxy) is a high-performance fluoropolymer prized for its extreme chemical inertness, a very wide operating temperature range, and excellent purity. It combines many of the best properties of PTFE (Teflon) with the significant advantage of being melt-processable, allowing it to be formed into more complex shapes.

PFA should be understood as a premium engineering material that solves problems in extreme environments. Its true value lies in providing the near-universal chemical and thermal resistance of PTFE in a form that can be injection molded or extruded, enabling designs that would otherwise be impossible.

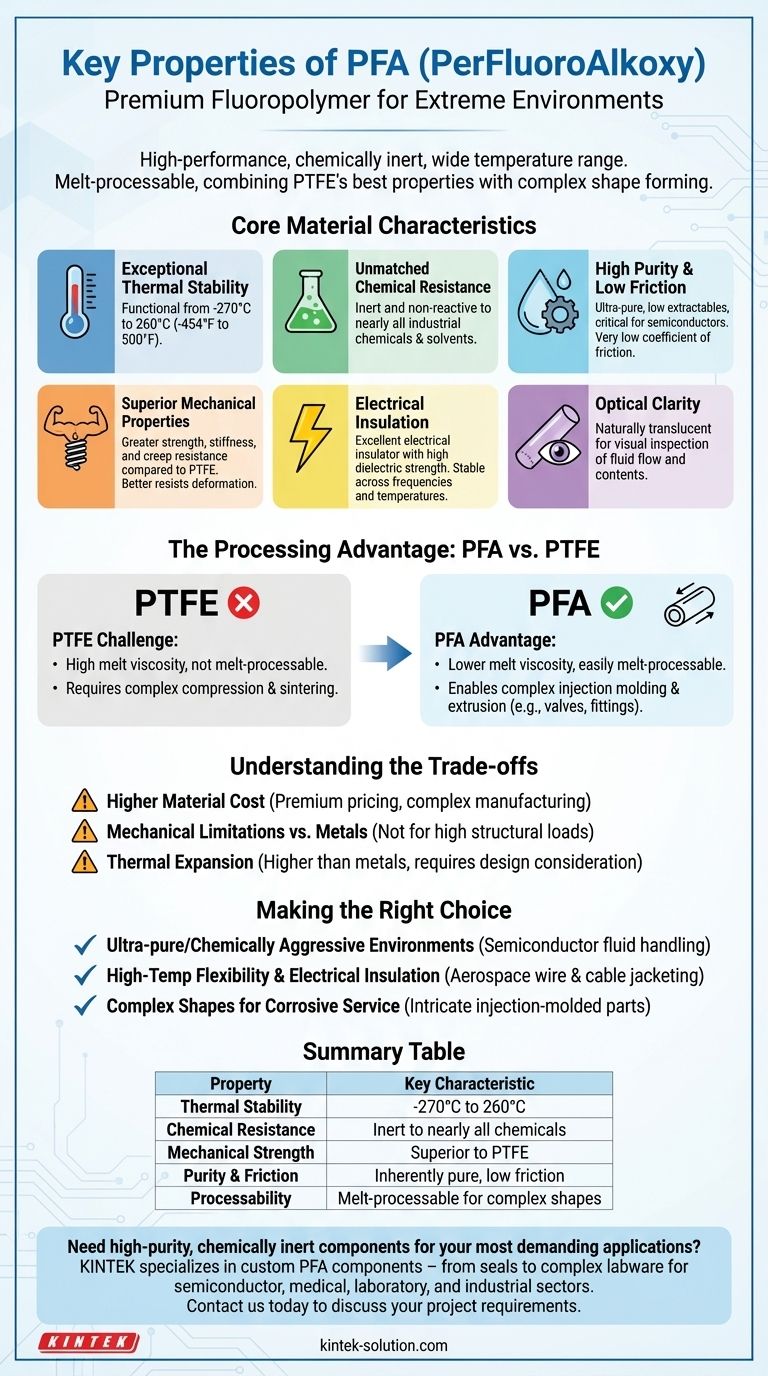

Core Material Characteristics

PFA’s unique combination of properties makes it a go-to choice for demanding applications where other materials would quickly fail.

Exceptional Thermal Stability

PFA maintains its integrity across an incredibly broad temperature spectrum. It is functional from cryogenic temperatures as low as -270°C (-454°F) up to a continuous service temperature of 260°C (500°F).

Unmatched Chemical Resistance

Like most fluoropolymers, PFA is chemically inert and non-reactive with nearly all industrial chemicals and solvents. This makes it ideal for handling highly corrosive or aggressive media.

High Purity and Low Friction

PFA is an inherently pure material with very low levels of extractables, which is critical for non-contaminating applications like semiconductor manufacturing and pharmaceuticals. It also possesses a very low coefficient of friction, characteristic of fluoropolymers.

Superior Mechanical Properties

Compared to its well-known relative PTFE, PFA offers greater strength, stiffness, and creep resistance. While still highly flexible, it better resists deformation under sustained load, especially at elevated temperatures.

Electrical Insulation

PFA is an excellent electrical insulator with a high dielectric strength. Its properties remain stable across a wide range of frequencies and temperatures, making it a reliable choice for critical electronic components and wire insulation.

Optical Clarity

The material is naturally translucent, which allows for visual inspection of fluid flow within PFA tubing or the contents of a PFA container. This can be a significant advantage in process monitoring.

The Processing Advantage: PFA vs. PTFE

Understanding why PFA exists requires comparing it to the most famous fluoropolymer, PTFE. The key difference isn't in performance—it's in manufacturability.

The Challenge of PTFE

PTFE has an extremely high melt viscosity, meaning it doesn't truly flow when heated. It cannot be processed using conventional techniques like injection molding or extrusion. Instead, it must be formed using a complex compression and sintering process, similar to powdered metallurgy.

PFA's Melt-Processability

PFA was engineered to solve this problem. It has a lower melt viscosity, allowing it to be easily processed using conventional thermoplastic methods. This unlocks the ability to create complex, injection-molded parts like valve bodies, fittings, and intricate components that would be impractical or impossible to machine from PTFE stock.

Understanding the Trade-offs

No material is perfect for every situation. Being objective about PFA's limitations is key to using it effectively.

Higher Material Cost

PFA is a premium polymer, and its cost reflects its performance and manufacturing complexity. It is significantly more expensive than standard engineering plastics and even other fluoropolymers like FEP.

Mechanical Limitations vs. Metals

While PFA is strong for a fluoropolymer, it is still a polymer. It cannot replace metals or high-strength ceramics in applications requiring high structural load-bearing capacity, especially at its upper temperature limits.

Thermal Expansion

Like all plastics, PFA has a relatively high coefficient of thermal expansion compared to metals. This must be accounted for in designs that involve large temperature fluctuations to avoid stress and failure.

Making the Right Choice for Your Application

Selecting PFA is a decision driven by the need for uncompromising performance in a hostile environment.

- If your primary focus is ultra-pure or chemically aggressive environments: PFA is a top-tier choice for semiconductor fluid handling, chemical processing tubing, and pharmaceutical equipment.

- If your primary focus is high-temperature flexibility and electrical insulation: PFA is ideal for demanding wire and cable jacketing, especially in aerospace or industrial applications with extreme temperatures.

- If your primary focus is creating complex shapes for corrosive service: Choose PFA when you need an intricate, injection-molded part that must withstand chemicals and temperatures that would destroy other polymers.

Ultimately, PFA provides a unique solution for engineering challenges where performance and reliability cannot be compromised.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Thermal Stability | Functional from -270°C to 260°C (-454°F to 500°F) |

| Chemical Resistance | Inert to nearly all industrial chemicals and solvents |

| Mechanical Strength | Superior strength, stiffness, and creep resistance vs. PTFE |

| Purity & Friction | Inherently pure with low extractables and a low coefficient of friction |

| Processability | Melt-processable for complex injection-molded or extruded shapes |

Need high-purity, chemically inert components for your most demanding applications?

KINTEK specializes in the custom fabrication of precision PFA components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your designs perform reliably in extreme thermal and chemical environments.

Contact us today to discuss your project requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand