The key features of a PTFE ball valve center on its material construction and operational design, making it a specialized component for demanding applications. Its primary characteristics include having all media-wetted surfaces made from chemically inert PTFE, reliable quarter-turn manual operation with very low torque, and a design that allows for simple flow metering.

At its core, a PTFE ball valve is an engineered solution for controlling highly corrosive or ultra-pure fluids where material compatibility and reliability are non-negotiable. Its features are a direct result of the unique properties of Polytetrafluoroethylene (PTFE).

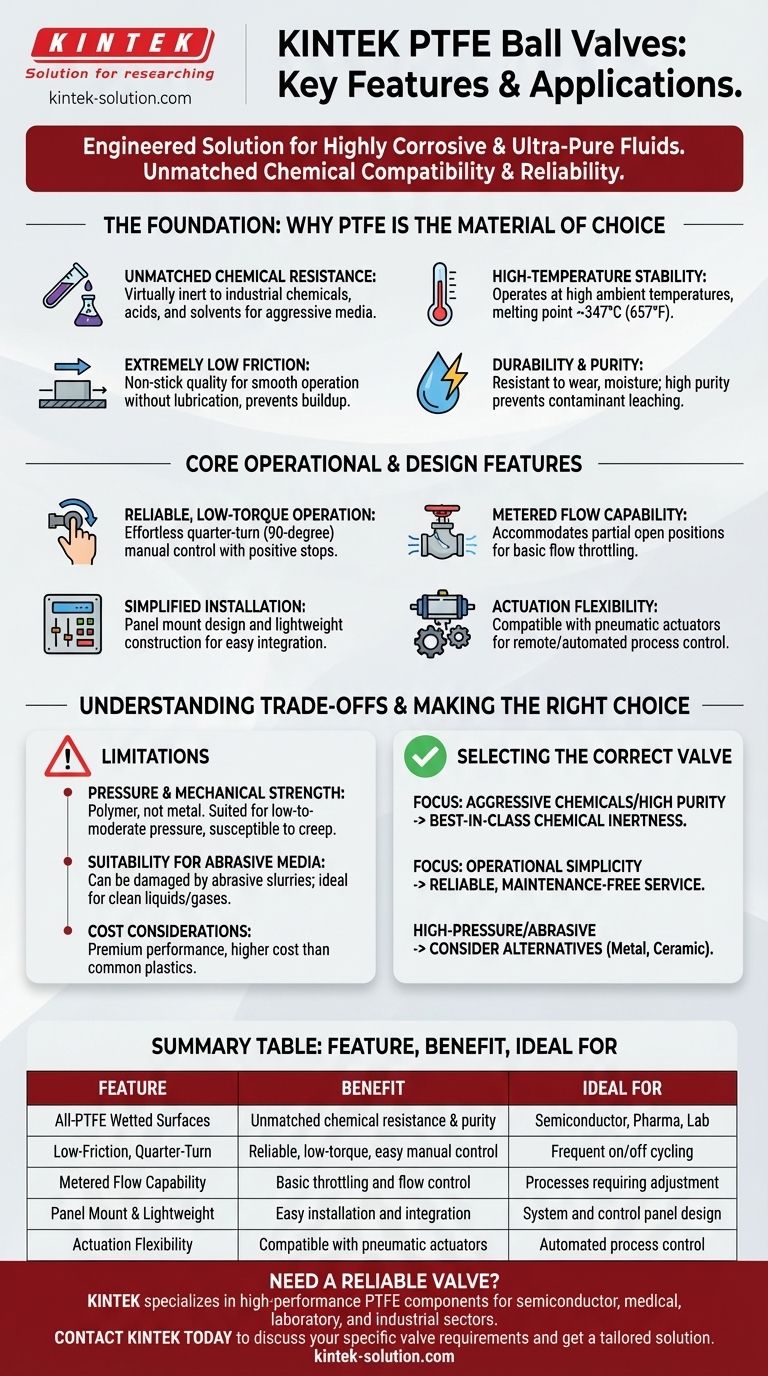

The Foundation: Why PTFE is the Material of Choice

The performance of these valves is inseparable from the distinct advantages of PTFE as an industrial polymer. Understanding these properties explains why this material is specified for critical applications.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to attack from the vast majority of industrial chemicals, acids, and solvents. This makes it the ideal choice for wetted surfaces that will be exposed to aggressive or corrosive media.

High-Temperature Stability

With a high melting point around 347°C (657°F), PTFE maintains its structural integrity and performance characteristics in high ambient temperature environments where many other plastics would fail.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick quality is critical, as it ensures smooth valve operation without the need for external lubrication and helps prevent media from building up on internal surfaces.

Durability and Purity

The material is highly resistant to wear, moisture, and electrical conductivity. Its inherent purity means it will not leach contaminants into the media, a crucial feature for semiconductor, pharmaceutical, and laboratory applications.

Core Operational and Design Features

Beyond the material science, PTFE ball valves are designed for straightforward and reliable use in industrial systems.

Reliable, Low-Torque Operation

The extremely low friction of the PTFE components allows the valve to be opened and closed with minimal physical effort. This is known as low torque operation.

The standard quarter-turn design moves the valve from fully open to fully closed with a simple 90-degree turn of the handle, which clicks into place against positive stops for a clear indication of its state.

Metered Flow Capability

While primarily an on/off valve, the design accommodates partial open positions. This allows a user to perform basic metering or throttling of the flow rate when precise control is not the primary requirement.

Simplified Installation and Integration

All models are typically designed with panel mount capabilities, allowing for clean and secure integration into control panels or system housings. Their lightweight construction also simplifies installation compared to heavier metal valves.

Actuation Flexibility

These valves can be operated manually with a simple lever or can be easily automated. They are often designed to connect to a pneumatic actuator via an adapter for remote or automated process control.

Understanding the Trade-offs and Limitations

No component is perfect for every scenario. To make an informed decision, it's critical to understand the inherent limitations of PTFE valves.

Pressure and Mechanical Strength

PTFE is a polymer, not a metal. While durable, it has lower mechanical strength and is more susceptible to "creep" or "cold flow" under high mechanical stress. Consequently, these valves are best suited for low-to-moderate pressure applications, not high-pressure hydraulic systems.

Suitability for Abrasive Media

The smooth, non-stick surface is ideal for clean liquids and gases. However, it can be scored or damaged by abrasive slurries or media containing hard particulates, which can compromise the integrity of the seal over time.

Cost Considerations

PTFE is a high-performance, premium polymer. While PTFE valves are often more cost-effective than those made from exotic metal alloys (like Hastelloy), they are typically more expensive than valves made from common plastics like PVC or polypropylene.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its features to the specific demands of your system.

- If your primary focus is handling aggressive chemicals or high-purity media: The valve's all-PTFE wetted path provides best-in-class chemical inertness and prevents media contamination.

- If your primary focus is operational simplicity and reliability: The low-friction, quarter-turn design ensures a long, maintenance-free service life with minimal effort to operate.

- If you are working with high-pressure systems or abrasive materials: You should carefully evaluate the valve's pressure ratings and consider alternatives like metal or specialized ceramic-lined valves.

Ultimately, choosing a PTFE ball valve is a decision to prioritize chemical compatibility and operational integrity for the most demanding fluid handling tasks.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| All-PTFE Wetted Surfaces | Unmatched chemical resistance & purity | Semiconductor, Pharma, Lab |

| Low-Friction, Quarter-Turn Operation | Reliable, low-torque, easy manual control | Frequent on/off cycling |

| Metered Flow Capability | Basic throttling and flow control | Processes requiring adjustment |

| Panel Mount & Lightweight | Easy installation and integration | System and control panel design |

| Actuation Flexibility | Compatible with pneumatic actuators | Automated process control |

Need a reliable valve for aggressive chemicals or ultra-pure media?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, labware, and custom-fabricated ball valves. Our expertise ensures precision production and material integrity for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, delivering the chemical resistance and operational reliability your process requires.

Contact KINTEK today to discuss your specific valve requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What size range do PTFE balls come in? A Guide from 3mm to 100mm