At its core, Polytetrafluoroethylene (PTFE) is prized for three dominant characteristics: exceptional chemical resistance, a vast operational temperature range, and an extremely low coefficient offriction. This unique combination makes it a default choice for sealing applications in highly aggressive or demanding environments where other materials would quickly fail.

PTFE is the premier gasket material for extreme chemical and thermal challenges. However, understanding the mechanical limitations of virgin PTFE—specifically its tendency to creep under pressure—is critical to selecting the correct type for reliable, long-term sealing.

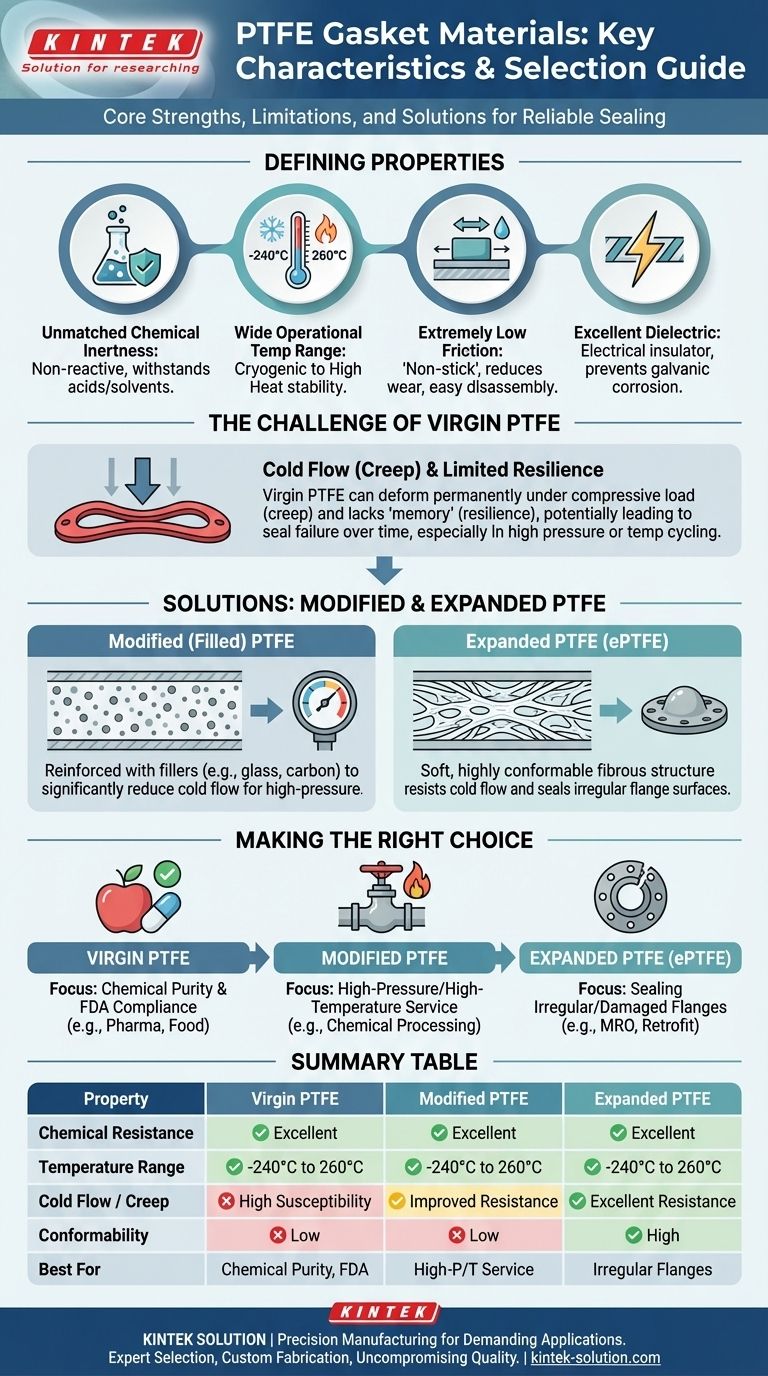

The Defining Properties of PTFE Gaskets

PTFE, a fluoropolymer, possesses a set of inherent qualities that make it exceptionally well-suited for industrial sealing. These properties establish its role as a high-performance material.

Unmatched Chemical Inertness

The most notable characteristic of PTFE is its near-total immunity to chemical attack. It is non-reactive and can withstand the most aggressive acids, solvents, and corrosive agents.

This makes it an indispensable material in chemical processing, pharmaceuticals, and any industry handling harsh fluids where contamination or material degradation is not an option.

Wide Operational Temperature Range

PTFE performs reliably across an exceptionally broad thermal spectrum. It maintains its integrity in cryogenic conditions as low as -400°F (-240°C) and in high-heat applications up to 500°F (260°C).

This stability allows a single material to be specified for processes that involve significant temperature fluctuations, simplifying design and inventory.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a distinct "non-stick" quality. This property reduces wear and tear in dynamic applications and prevents material buildup on the gasket surface.

This non-adhesive nature also makes for easier disassembly and cleaning of flanged joints, as the gasket material does not bond to the sealing surfaces.

Excellent Dielectric Properties

In its virgin form, PTFE is an outstanding electrical insulator. It does not conduct electricity, making it an ideal choice for applications where electrical isolation between flanges is required.

This property is crucial in preventing galvanic corrosion between dissimilar metals or in isolating electrically sensitive equipment.

Understanding the Trade-offs of Virgin PTFE

While its chemical and thermal properties are superb, standard (virgin) PTFE has mechanical limitations that must be understood to prevent seal failure. These trade-offs are the primary reason that modified and expanded versions of PTFE were developed.

The Challenge of "Cold Flow" (Creep)

The primary weakness of virgin PTFE is its susceptibility to cold flow, or creep. When placed under compressive load, the material can slowly and permanently deform over time.

This can lead to a loss of bolt torque and a reduction in sealing pressure, eventually causing the seal to leak. This is especially prevalent in applications with high pressure or significant temperature cycling.

Limited Memory and Resilience

Unlike rubber elastomers, virgin PTFE has very poor "memory." It does not readily spring back to its original shape after being compressed.

This lack of resilience can be problematic in applications involving vibration or flange movement, where a gasket needs to adapt dynamically to maintain a tight seal.

How Modified PTFE Overcomes Limitations

To address the mechanical weaknesses of virgin PTFE, manufacturers have developed filled and expanded variants that offer superior performance in demanding physical conditions.

Modified (Filled) PTFE

In this version, inert filler materials are blended into the virgin PTFE resin. Common fillers include glass, silica, or carbon.

These fillers act as a reinforcing matrix within the material, significantly reducing cold flow and improving the gasket's ability to maintain its shape under load. This makes filled PTFE a much better choice for high-pressure service.

Expanded PTFE (ePTFE)

Expanded PTFE is a soft, highly conformable material created by mechanically stretching PTFE. This process creates a multidirectional fibrous structure.

This structure gives ePTFE excellent resistance to cold flow while retaining the outstanding chemical and thermal properties of virgin PTFE. Its softness allows it to conform easily to rough or irregular flange surfaces, creating a reliable seal with lower bolt torque.

Making the Right Choice for Your Goal

Selecting the correct PTFE gasket requires matching the material's properties to the specific demands of your service conditions.

- If your primary focus is chemical purity and FDA compliance: Virgin PTFE is the ideal choice for food, beverage, and pharmaceutical applications where non-contamination is paramount.

- If your primary focus is sealing high-pressure or high-temperature lines: A modified (filled) PTFE provides the necessary creep resistance to ensure a durable, long-lasting seal.

- If your primary focus is sealing old, damaged, or irregular flanges: Expanded PTFE (ePTFE) offers superior conformability, creating a tight seal where rigid gaskets would fail.

Ultimately, choosing the right PTFE variant transforms a potential point of failure into a component of exceptional reliability.

Summary Table:

| Property | Virgin PTFE | Modified (Filled) PTFE | Expanded PTFE (ePTFE) |

|---|---|---|---|

| Chemical Resistance | Excellent | Excellent | Excellent |

| Temperature Range | -240°C to 260°C | -240°C to 260°C | -240°C to 260°C |

| Cold Flow / Creep | High Susceptibility | Improved Resistance | Excellent Resistance |

| Conformability | Low | Low | High |

| Best For | Chemical Purity, FDA Compliance | High-Pressure/High-Temperature Service | Irregular/Damaged Flanges |

Need a PTFE Gasket Solution for Your Demanding Application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, gaskets, liners, and custom labware. Whether your industry is semiconductor, medical, laboratory, or industrial, we understand the critical need for reliable sealing in aggressive environments.

We provide:

- Expert Material Selection: Guidance on choosing the right PTFE variant (Virgin, Filled, or ePTFE) for your specific chemical, thermal, and pressure requirements.

- Custom Fabrication: From initial prototypes to high-volume production runs, we manufacture components to your exact specifications.

- Uncompromising Quality: Our focus on precision ensures a perfect seal and long-term reliability for your equipment.

Let us help you transform a potential point of failure into a component of exceptional reliability.

Contact our engineering team today for a consultation on your PTFE gasket needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability