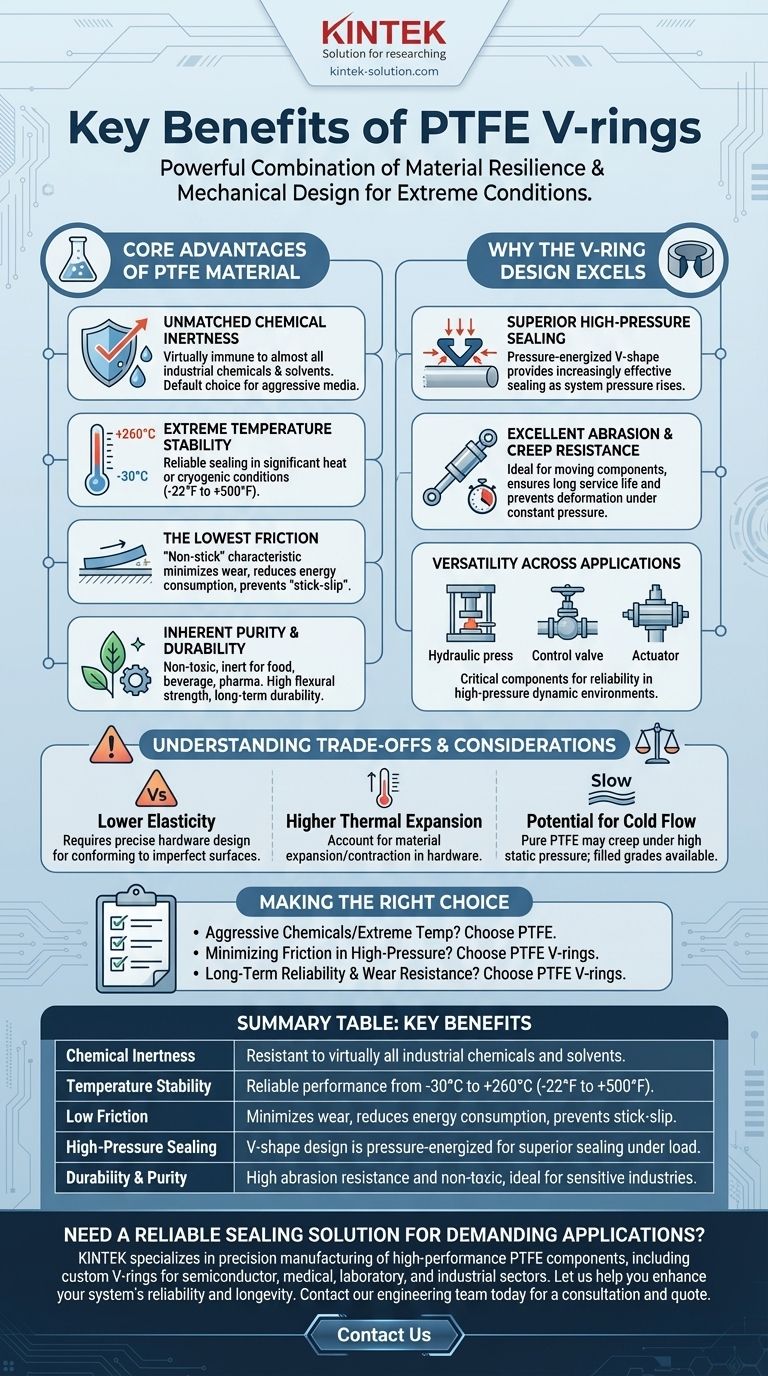

At their core, PTFE V-rings offer a powerful combination of material resilience and mechanical design. They are primarily valued for their exceptional chemical resistance, broad temperature tolerance, extremely low friction, and suitability for high-pressure sealing applications.

The central challenge in advanced sealing is finding a solution that won't degrade under extreme chemical, thermal, or mechanical stress. PTFE V-rings solve this by pairing the inherent inertness of Polytetrafluoroethylene (PTFE) with a V-shaped profile specifically engineered to handle high-pressure, dynamic environments.

The Core Advantages of the PTFE Material

The foundation of a V-ring's performance lies in the unique properties of Polytetrafluoroethylene. This material provides a level of resilience that conventional elastomers cannot match.

Unmatched Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals and solvents. This makes it the default choice for systems handling aggressive media where other seal materials would quickly fail.

Extreme Temperature Stability

This material maintains its integrity across a vast temperature range, typically from -30°C up to +260°C (-22°F to +500°F). This stability ensures reliable sealing in applications involving significant heat or cryogenic conditions.

The Lowest Friction of Any Solid

PTFE possesses an exceptionally low coefficient of friction. This "non-stick" characteristic minimizes wear on moving parts, reduces energy consumption, and prevents the "stick-slip" motion common in hydraulic systems.

Inherent Purity and Durability

Being non-toxic and inert, PTFE is well-suited for applications in the food, beverage, and pharmaceutical industries. Its strong carbon-fluorine bonds also grant it high flexural strength and long-term durability.

Why the V-Ring Design Excels

While the material is critical, the V-ring's specific shape is engineered to leverage these properties for demanding mechanical tasks, particularly in dynamic sealing.

Superior High-Pressure Sealing

The V-shape is designed to be pressure-energized. As system pressure increases, it acts on the "V," forcing the sealing lips more firmly against the hardware, creating an increasingly effective seal. They are often used in stacks for very high-pressure applications.

Excellent Abrasion and Creep Resistance

This combination is ideal for sealing on moving components like hydraulic cylinder rods, plungers, and valve spindles. The material's abrasion resistance ensures a long service life, while its good creep resistance prevents the seal from deforming under constant pressure.

Versatility Across Applications

The benefits of the material and design make PTFE V-rings a versatile solution. They are critical components in hydraulic presses, control valves, and various actuators where reliability under pressure is non-negotiable.

Understanding the Trade-offs and Considerations

No single solution is perfect for every scenario. To make an informed decision, it's crucial to understand the inherent trade-offs of PTFE.

Lower Elasticity Compared to Rubber

PTFE is a relatively rigid plastic and lacks the "memory" or elasticity of rubber elastomers. This means it may not be the best choice for applications requiring a high degree of conformance to imperfect surfaces at very low pressures without a separate energizing element.

Higher Thermal Expansion

The material can expand and contract significantly with temperature changes. This coefficient of thermal expansion must be accounted for in the hardware design to prevent the seal from becoming too loose or too tight.

Potential for Cold Flow

While V-ring designs mitigate this, pure, unfilled PTFE can be susceptible to "creep" or cold flow—a slow, continuous deformation under a constant load. For applications with very high static pressures, a filled grade of PTFE may be required.

Making the Right Choice for Your Application

Your final decision should be guided by the most critical demand of your system.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures: The near-universal chemical inertness and broad temperature stability of PTFE are its most significant advantages.

- If your primary focus is minimizing friction in a high-pressure dynamic system: The V-ring design, combined with PTFE's uniquely low coefficient of friction, is ideal for hydraulic rods and plungers.

- If your primary focus is ensuring long-term reliability and wear resistance: The combination of high abrasion resistance and the pressure-actuated V-ring design provides a durable, long-lasting sealing solution.

Ultimately, selecting a PTFE V-ring is a strategic choice for sealing applications where performance and reliability cannot be compromised.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Resistant to virtually all industrial chemicals and solvents. |

| Temperature Stability | Reliable performance from -30°C to +260°C (-22°F to +500°F). |

| Low Friction | Minimizes wear, reduces energy consumption, and prevents stick-slip. |

| High-Pressure Sealing | V-shape design is pressure-energized for superior sealing under load. |

| Durability & Purity | High abrasion resistance and non-toxic, ideal for sensitive industries. |

Need a Reliable Sealing Solution for Demanding Applications?

PTFE V-rings are a strategic choice for sealing systems where performance under extreme chemical, thermal, and pressure conditions is non-negotiable.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom V-rings. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume production.

Let us help you enhance your system's reliability and longevity. Our expertise ensures you get the right seal for your specific application challenges.

Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance