In high-pressure applications, PTFE rotary shaft lip seals offer a distinct set of advantages rooted in the material's fundamental properties. They provide superior chemical and temperature resistance, generate significantly less friction, and maintain sealing integrity at high rotational speeds, directly addressing the common failure points of traditional elastomeric seals in demanding environments.

The core issue with high-pressure systems is that they magnify the weaknesses of conventional seals, leading to heat damage, chemical degradation, and premature wear. PTFE seals excel because their inherent low friction and chemical inertness directly counteract these forces, ensuring longer service life and greater operational reliability.

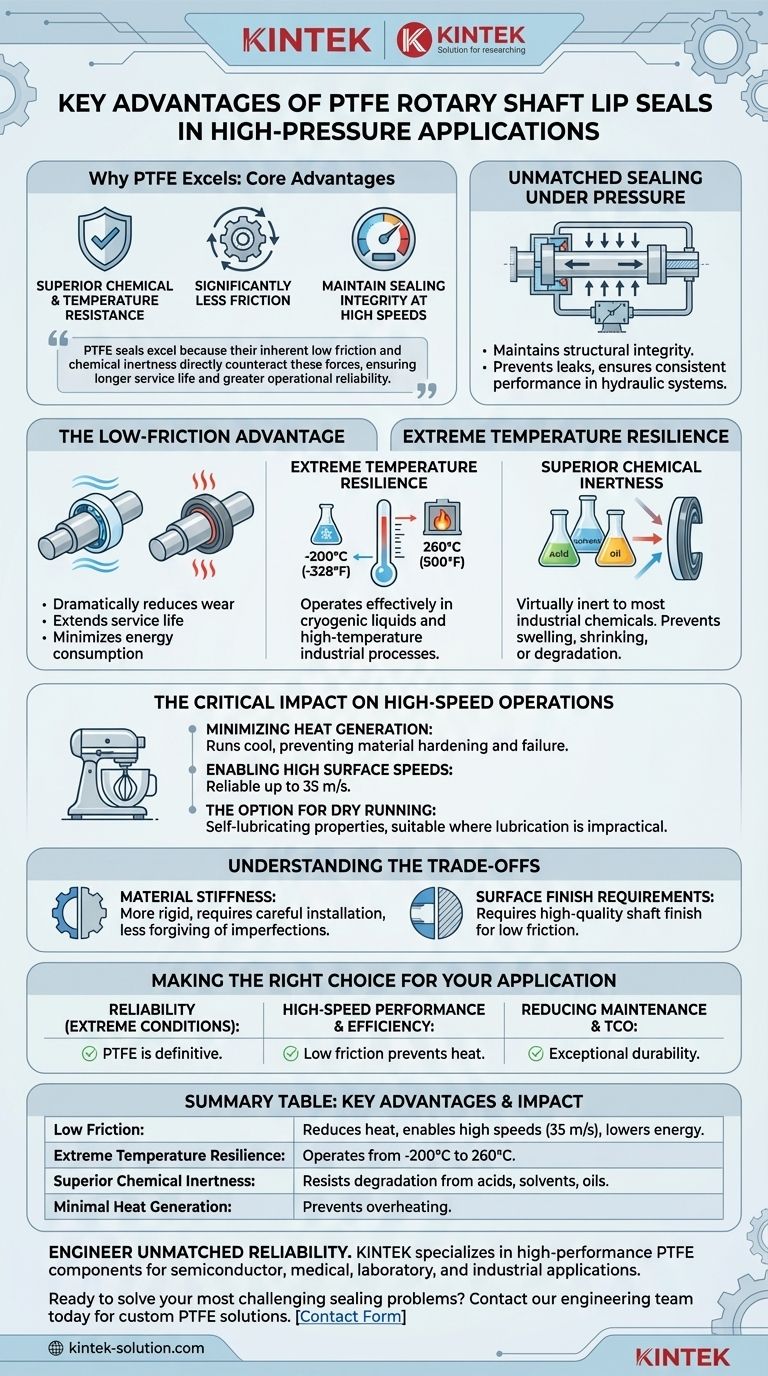

Why PTFE Excels Where Traditional Seals Fail

To understand the value of PTFE, we must look at the specific environmental stresses it is designed to overcome. High pressure, speed, and aggressive media create a hostile environment where most sealing materials quickly degrade.

Unmatched Sealing Under Pressure

PTFE (polytetrafluoroethylene) maintains its structural integrity and sealing force under significant pressure. Unlike some elastomers that can deform or extrude, PTFE provides a stable and reliable barrier.

This stability prevents leaks and ensures consistent performance, which is critical for the safety and efficiency of hydraulic systems and other high-pressure equipment.

The Low-Friction Advantage

A key differentiator for PTFE is its extremely low coefficient of friction. This property translates into several direct operational benefits.

First, it dramatically reduces wear on both the seal and the rotary shaft, extending the service life of both components and lowering maintenance costs. Second, it minimizes the energy required to turn the shaft, contributing to overall system efficiency.

Extreme Temperature Resilience

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -200°C (-328°F) to 260°C (500°F).

This makes them the default choice for applications involving cryogenic liquids or high-temperature industrial processes where rubber or other polymer seals would become brittle or melt.

Superior Chemical Inertness

PTFE is virtually inert to most industrial chemicals, including aggressive acids, solvents, bases, and oils.

This chemical resistance prevents the seal from swelling, shrinking, or degrading upon exposure, ensuring a reliable seal and preventing contamination of the system media.

The Critical Impact on High-Speed Operations

In many industrial applications, high pressure is accompanied by high rotational speeds. This combination is particularly punishing for seals, as it generates significant frictional heat.

Minimizing Heat Generation

Because PTFE has such low friction, it generates far less heat than other materials at high speeds. This is arguably its most critical advantage in these applications.

Excessive heat is a primary cause of seal failure, as it can lead to material hardening, cracking, and a loss of sealing capability. PTFE's ability to run cool prevents this entire failure cycle.

Enabling High Surface Speeds

The low heat generation allows PTFE seals to perform reliably at shaft surface speeds of up to 35 m/s.

This capability is essential for equipment like high-speed mixers, pumps, and compressors where traditional seals would quickly overheat and fail.

The Option for Dry Running

The self-lubricating properties of PTFE mean that these seals can often function effectively without external lubrication.

This is a significant benefit in applications where lubrication is impractical, undesirable (e.g., food processing), or could contaminate the system.

Understanding the Trade-offs

While PTFE offers superior performance in demanding conditions, it is important to recognize its unique material characteristics. It is not simply a drop-in replacement for every rubber seal.

Material Stiffness

PTFE is a more rigid material than common elastomers like nitrile or Viton. It has less elasticity and "memory."

This means that installation requires care to avoid damaging the seal lip. It also means the seal is less forgiving of shaft imperfections or significant runout compared to a more flexible rubber seal.

Surface Finish Requirements

To leverage the low-friction benefit of PTFE, the mating shaft surface must have a high-quality finish.

Any roughness on the shaft can cause premature wear on the stiffer PTFE lip. Adhering to manufacturer specifications for surface finish is critical for achieving a long service life.

Making the Right Choice for Your Application

Ultimately, selecting a PTFE seal is a strategic decision based on the operational demands of your equipment.

- If your primary focus is reliability in extreme temperatures or aggressive chemical environments: PTFE is the definitive choice due to its fundamental material stability.

- If your primary focus is high-speed performance and efficiency: PTFE's low-friction properties will prevent heat buildup and reduce energy consumption.

- If your primary focus is reducing maintenance and total cost of ownership: The exceptional durability and long service life of PTFE seals reduce equipment downtime and replacement costs.

By understanding these core advantages, you can confidently specify PTFE seals for your most challenging applications, ensuring greater reliability and performance.

Summary Table:

| Key Advantage | Impact in High-Pressure Applications |

|---|---|

| Low Friction | Reduces heat generation, enables high speeds (up to 35 m/s), and lowers energy consumption. |

| Extreme Temperature Resilience | Operates reliably from -200°C to 260°C, suitable for cryogenic and high-heat processes. |

| Superior Chemical Inertness | Resists degradation from acids, solvents, and oils, ensuring seal integrity. |

| Minimal Heat Generation | Prevents the primary cause of seal failure (overheating) in demanding conditions. |

Engineer Unmatched Reliability for Your High-Pressure Equipment

PTFE seals are not just a component; they are a critical investment in the uptime and efficiency of your machinery. For semiconductor, medical, laboratory, and industrial applications, the right seal makes all the difference.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom rotary shaft seals. We understand the exacting demands of high-pressure, high-speed environments. Whether you need a prototype for testing or a high-volume production run, our expertise ensures you get a seal that delivers superior chemical resistance, minimal friction, and long-lasting performance.

Ready to solve your most challenging sealing problems? Contact our engineering team today to discuss your specific requirements and how our custom PTFE solutions can enhance your equipment's reliability and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments