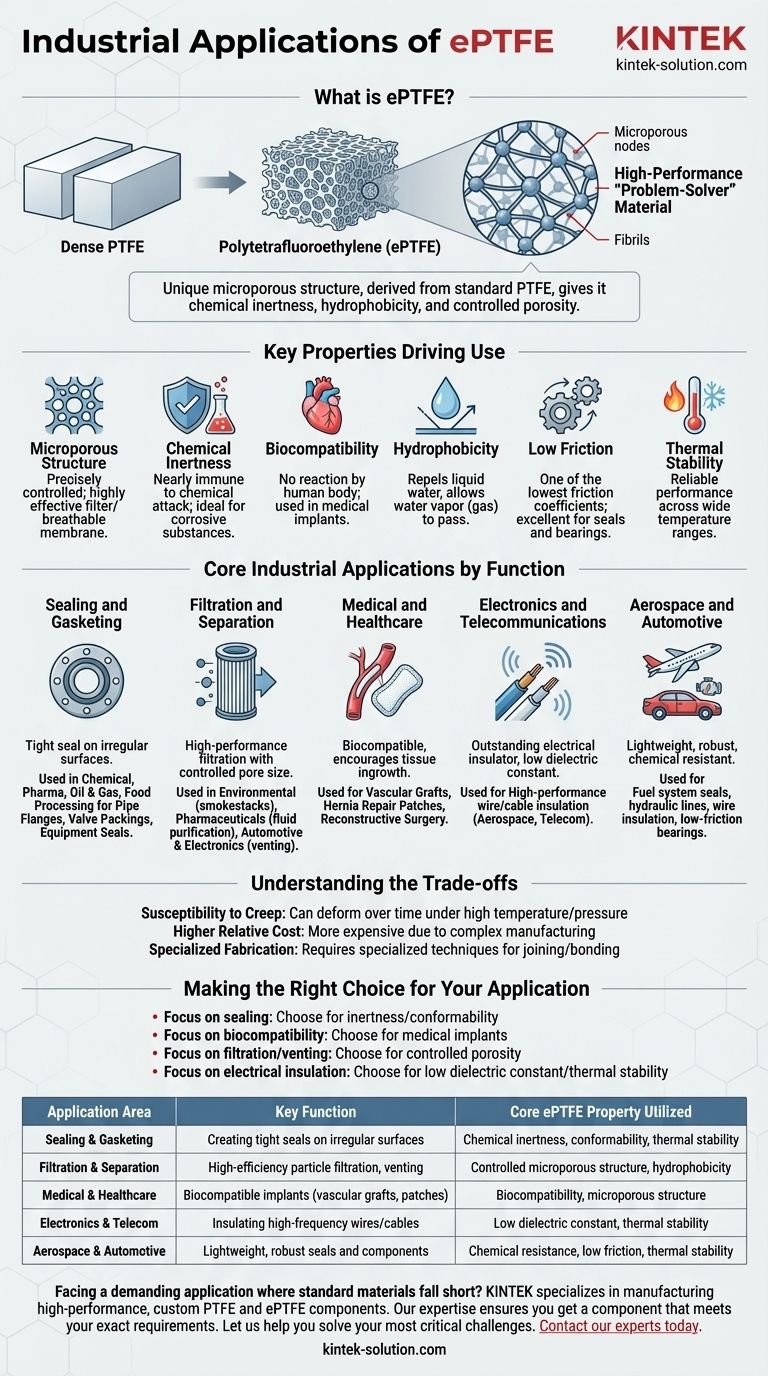

At its core, expanded Polytetrafluoroethylene (ePTFE) is a critical material in industries where performance under extreme conditions is non-negotiable. Its unique microporous structure, derived from standard PTFE, gives it a combination of properties—chemical inertness, hydrophobicity, and controlled porosity—that makes it indispensable in sectors ranging from medical and aerospace to chemical processing and electronics.

The versatility of ePTFE stems not just from its base material (PTFE), but from the "expansion" process itself. This process creates a unique microstructure of nodes and fibrils, turning a simple polymer into a high-performance material capable of solving complex challenges in sealing, filtration, and biocompatibility.

Why ePTFE Is a "Problem-Solver" Material

Understanding ePTFE's applications requires looking at the specific material properties that engineers leverage. It is rarely chosen for simple tasks; it is specified when other materials fail.

From PTFE to ePTFE: The Key Transformation

Standard PTFE (well-known by the brand name Teflon) is a dense, slick polymer. The creation of ePTFE involves mechanically stretching this material under controlled conditions.

This stretching process pulls the polymer's molecules apart, creating a web-like, microporous structure. This structure is what imbues ePTFE with its most valuable and unique characteristics.

The Properties Driving Its Widespread Use

Every application of ePTFE can be traced back to one or more of these fundamental properties.

- Microporous Structure: The network of pores can be precisely controlled, allowing ePTFE to function as a highly effective filter or a breathable, waterproof membrane.

- Chemical Inertness: Like its parent material, ePTFE is nearly immune to chemical attack, making it ideal for handling corrosive substances.

- Biocompatibility: The human body does not react to ePTFE, a critical property that allows it to be used inside the body for medical implants.

- Hydrophobicity: ePTFE repels liquid water but allows water vapor (gas) to pass through its pores, a key feature for venting and protective apparel.

- Low Friction: It has one of the lowest coefficients of friction of any solid, making it excellent for low-wear seals and bearings.

- Thermal Stability: It performs reliably across an exceptionally wide range of temperatures.

Core Industrial Applications by Function

Instead of just listing industries, it's more instructive to group applications by the function ePTFE serves. This reveals how its core properties are put to work.

Sealing and Gasketing

This is one of the most common uses for ePTFE. Its softness and conformability allow it to create a tight seal even on irregular or damaged surfaces.

It is heavily used in the chemical, pharmaceutical, oil & gas, and food processing industries for pipe flanges, valve packings, and equipment seals where chemical resistance and temperature stability are paramount.

Filtration and Separation

The precisely controlled pore size of ePTFE membranes makes them exceptional for high-performance filtration.

Applications include environmental filtration (capturing pollutants from industrial smokestacks), fluid purification in pharmaceuticals, and venting for automotive and electronics enclosures, which must block water while allowing air to pass.

Medical and Healthcare

ePTFE's biocompatibility is its defining feature in this sector. The body does not reject it, and its porous structure can encourage the ingrowth of natural tissue.

It is used to create vascular grafts (artificial blood vessels), patches for hernia repair, and materials for reconstructive surgery.

Electronics and Telecommunications

ePTFE is an outstanding electrical insulator with a very low dielectric constant, meaning it does not interfere with high-frequency electronic signals.

This makes it a superior material for insulating high-performance wires and cables, particularly in the aerospace and telecommunications industries where signal integrity is critical.

Aerospace and Automotive

In these demanding sectors, materials must be lightweight yet robust, resisting chemicals like fuel and hydraulic fluid across extreme temperatures.

ePTFE is used for fuel system seals, hydraulic lines, wire insulation, and low-friction bearings, contributing to both reliability and performance.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of ePTFE is crucial for making an informed decision.

Susceptibility to Creep

Under a combination of high temperature and sustained pressure, ePTFE can slowly deform over time—a phenomenon known as "creep" or "cold flow." This must be accounted for in the design of high-load structural components.

Higher Relative Cost

The complex manufacturing process makes ePTFE significantly more expensive than standard plastics or even basic PTFE. Its use is typically justified only when its unique performance characteristics are a strict requirement.

Specialized Fabrication

Joining, bonding, or forming ePTFE often requires specialized techniques and equipment. It is not as easily fabricated as more common engineering materials.

Making the Right Choice for Your Application

Your final decision depends entirely on the primary problem you need to solve.

- If your primary focus is sealing against harsh chemicals: ePTFE's inertness and conformability make it a premier choice for gaskets and packings, especially on imperfect surfaces.

- If your primary focus is biocompatible medical implants: Its inert, microporous nature is unmatched for applications like vascular grafts and surgical patches that must integrate with the body.

- If your primary focus is high-efficiency filtration or venting: The controlled porosity of ePTFE membranes offers superior performance for separating particles or protecting sensitive electronics from liquid ingress.

- If your primary focus is electrical insulation for high-frequency signals: Its low dielectric constant and thermal stability make it an essential material for aerospace and telecommunications cables.

Ultimately, ePTFE is chosen when conventional materials cannot meet the demands of the operating environment, offering a unique solution for the most critical industrial challenges.

Summary Table:

| Application Area | Key Function | Core ePTFE Property Utilized |

|---|---|---|

| Sealing & Gasketing | Creating tight seals on irregular surfaces | Chemical inertness, conformability, thermal stability |

| Filtration & Separation | High-efficiency particle filtration, venting | Controlled microporous structure, hydrophobicity |

| Medical & Healthcare | Biocompatible implants (vascular grafts, patches) | Biocompatibility, microporous structure |

| Electronics & Telecom | Insulating high-frequency wires/cables | Low dielectric constant, thermal stability |

| Aerospace & Automotive | Lightweight, robust seals and components | Chemical resistance, low friction, thermal stability |

Facing a demanding application where standard materials fall short?

KINTEK specializes in manufacturing high-performance, custom PTFE and ePTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a component that meets your exact requirements for chemical resistance, thermal stability, or biocompatibility.

Let us help you solve your most critical challenges. Contact our experts today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications