The four primary types of Teflon™ resins are PTFE, FEP, PFA, and ETFE. While all are fluoropolymers sharing core properties like chemical inertness and low friction, they are not interchangeable. Each resin offers a distinct combination of temperature resistance, mechanical strength, and processability, making them suitable for different applications.

The central challenge when selecting a Teflon resin is balancing performance against processability. PTFE offers the highest temperature resistance but is difficult to process, while FEP, PFA, and ETFE can be melt-processed like conventional plastics, each with its own unique set of trade-offs in heat tolerance and durability.

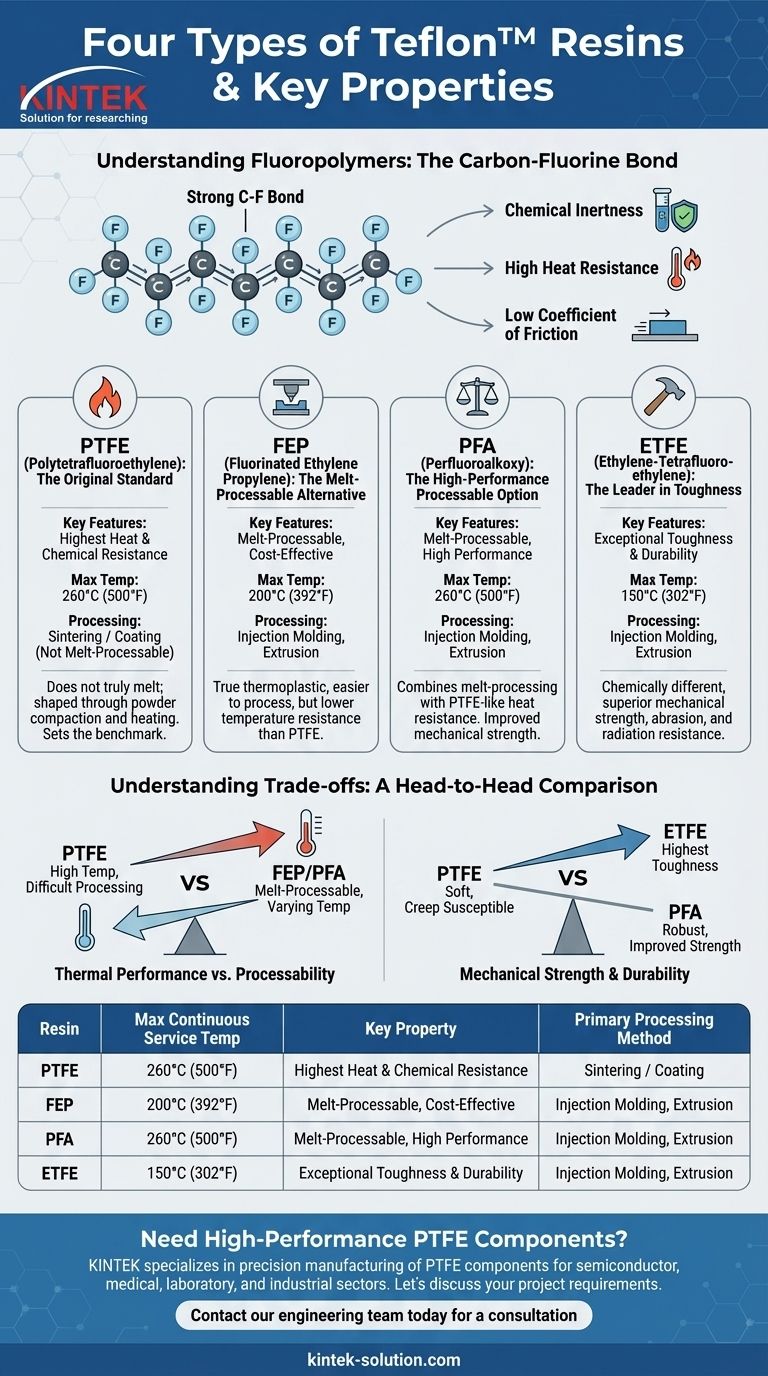

The Core of Teflon: Understanding Fluoropolymers

Before comparing the types, it's crucial to understand what gives them their shared characteristics. The strength of the carbon-fluorine bond is the foundation of their performance.

### The Carbon-Fluorine Bond

At a molecular level, Teflon resins are long chains of carbon atoms surrounded by fluorine atoms. This bond is exceptionally strong and stable.

This structure is responsible for the material's signature properties: chemical inertness, high heat resistance, and an extremely low coefficient of friction (its "non-stick" quality).

### General Physical Properties

Across the family, these resins are excellent electrical insulators, absorb very little water, and maintain their properties across a wide range of temperatures. They are dense materials, typically around 2.2 g/cm³.

The Four Primary Teflon Resins Explained

Each of the four main types modifies the core fluoropolymer structure to optimize for specific performance needs.

### PTFE (Polytetrafluoroethylene): The Original Standard

PTFE is the original and most widely known Teflon resin. It sets the benchmark for temperature resistance and chemical inertness.

Its key characteristic is that it does not truly melt. Instead of flowing like a liquid, it becomes a gel that cannot be processed using conventional techniques like injection molding. It is typically shaped through sintering—a process of compacting and heating powder.

### FEP (Fluorinated Ethylene Propylene): The Melt-Processable Alternative

FEP was developed to address PTFE's processing limitations. It is a true thermoplastic, meaning it can be melt-processed using injection molding and extrusion.

This ease of processing comes at the cost of a lower service temperature, typically around 200°C, compared to PTFE's 260°C. It is also softer than PTFE.

### PFA (Perfluoroalkoxy): The High-Performance Processable Option

PFA combines the benefits of the previous two. It is melt-processable like FEP but offers heat resistance that is nearly identical to PTFE.

PFA is often considered a premium resin for applications that require the performance of PTFE but need the design flexibility of injection molding. It generally has better mechanical strength than PTFE and FEP.

### ETFE (Ethylene-Tetrafluoroethylene): The Leader in Toughness

ETFE is chemically different from the others but is still part of the fluoropolymer family. Its defining feature is exceptional mechanical strength and toughness.

While its temperature resistance (around 150°C) is lower than the others, it is far more durable and resistant to abrasion and radiation. This makes it ideal for demanding architectural applications, wire insulation, and coatings on chemical equipment.

Understanding the Trade-offs: A Head-to-Head Comparison

Choosing the right resin requires a clear understanding of what you are gaining and what you are giving up with each option.

### Thermal Performance vs. Processability

This is the most critical trade-off. PTFE offers the highest heat resistance but cannot be injection molded.

FEP and PFA solve this problem, allowing for the creation of complex parts through conventional melt processing. PFA nearly matches PTFE's heat resistance, while FEP offers a lower-cost but also lower-temperature alternative.

### Mechanical Strength and Durability

If your primary concern is toughness, abrasion, or tear resistance, ETFE is the clear winner. It behaves more like an engineering plastic.

PTFE is relatively soft and can be susceptible to "creep" or cold flow under load. PFA offers improved mechanical properties over both PTFE and FEP, making it a robust, all-around performer.

### Application Forms

The way a resin is processed dictates the forms it comes in. PTFE is often applied as a liquid coating (dispersion) or sintered from a fine powder.

FEP, PFA, and ETFE are available as pellets or powders suitable for extrusion and injection molding, allowing for the fabrication of solid components, films, and wire insulation.

Making the Right Choice for Your Application

Your final decision should be driven by the most critical requirement of your project.

- If your primary focus is maximum heat and chemical resistance: PTFE remains the gold standard, provided your part can be manufactured through sintering or applied as a coating.

- If your primary focus is creating complex parts via injection molding: PFA is the choice for high-temperature applications, while FEP is a more economical option for less demanding thermal environments.

- If your primary focus is mechanical toughness, durability, and abrasion resistance: ETFE is the superior option, especially for films, wire insulation, and protective coatings.

- If your primary focus is balancing high performance with design flexibility: PFA often provides the best compromise, delivering near-PTFE temperature resistance with the ease of melt-processing.

Ultimately, selecting the correct fluoropolymer is about matching the material's unique strengths to your specific engineering challenge.

Summary Table:

| Resin | Max Continuous Service Temp | Key Property | Primary Processing Method |

|---|---|---|---|

| PTFE | 260°C (500°F) | Highest Heat & Chemical Resistance | Sintering / Coating |

| FEP | 200°C (392°F) | Melt-Processable, Cost-Effective | Injection Molding, Extrusion |

| PFA | 260°C (500°F) | Melt-Processable, High Performance | Injection Molding, Extrusion |

| ETFE | 150°C (302°F) | Exceptional Toughness & Durability | Injection Molding, Extrusion |

Need High-Performance PTFE Components?

Choosing the right resin is just the first step. KINTEK specializes in the precision manufacturing of PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance of properties required for your application. Whether you need prototypes or high-volume production, our expertise in custom fabrication ensures you get components that meet your exact specifications for performance and durability.

Let's discuss your project requirements and find the optimal solution together.

Contact our engineering team today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments