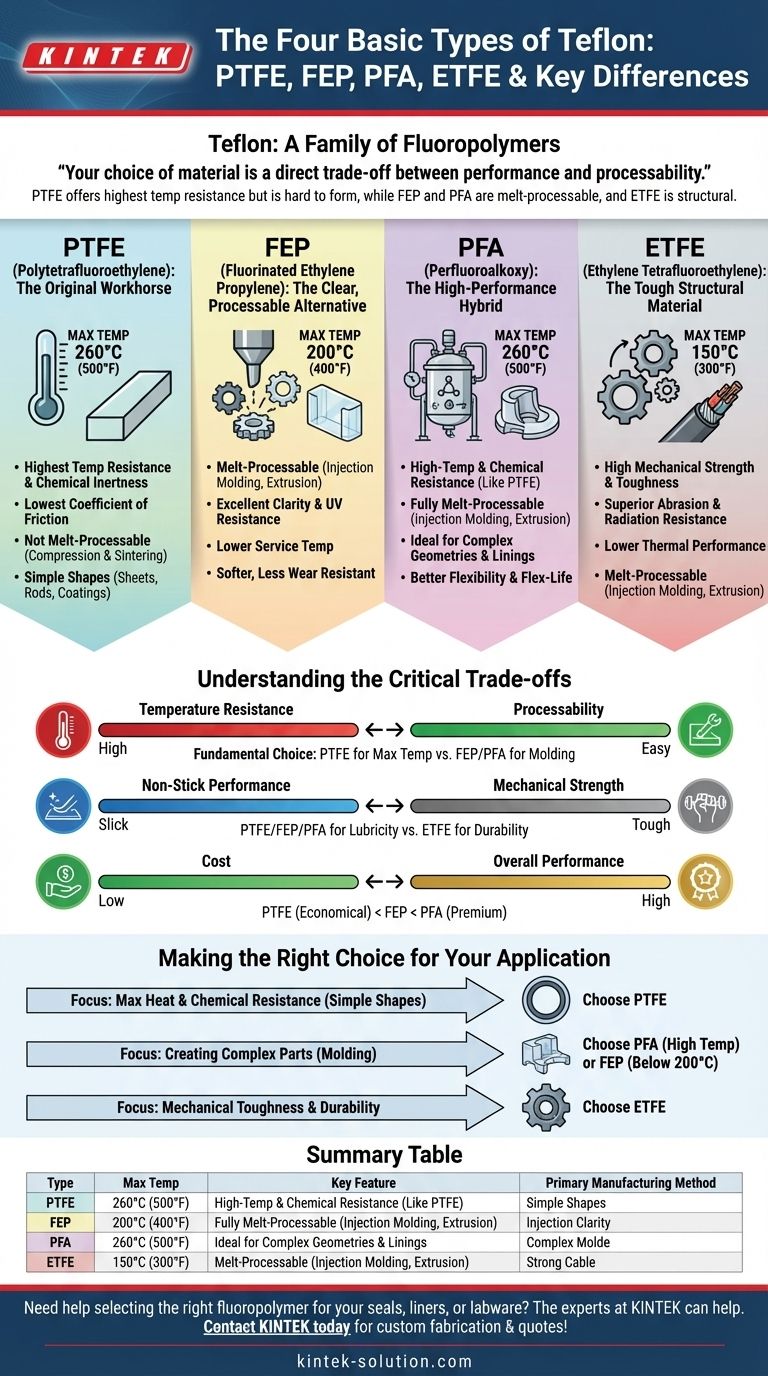

In technical terms, "Teflon" is not a single material but a brand name for a family of fluoropolymers. The four foundational types are PTFE (Polytetrafluoroethylene), FEP (Fluorinated Ethylene Propylene), PFA (Perfluoroalkoxy), and ETFE (Ethylene Tetrafluoroethylene). While all share exceptional chemical inertness and non-stick properties, they differ critically in their thermal resistance, mechanical strength, and how they can be manufactured into final parts.

Your choice of material is a direct trade-off between performance and processability. PTFE offers the highest temperature resistance but is difficult to form, while FEP and PFA were engineered to be easily melt-processed, with ETFE standing apart as a mechanically robust, structural alternative.

A Deeper Look at Each Fluoropolymer

While often grouped together, each of the four primary types of Teflon was designed to solve a different set of engineering problems. Understanding their unique profiles is the key to proper material selection.

PTFE (Polytetrafluoroethylene): The Original Workhorse

PTFE is the original and most widely known fluoropolymer. It sets the benchmark for performance in several key areas.

Its defining characteristics are the highest operating temperature (up to 260°C or 500°F), the lowest coefficient of friction of any solid material, and near-universal chemical resistance.

The critical limitation of PTFE is that it is not melt-processable. It cannot be injection molded or extruded like a typical thermoplastic. Instead, it must be compressed and sintered—a process that limits it to simpler shapes like sheets, rods, tubes, and coatings.

FEP (Fluorinated Ethylene Propylene): The Clear, Processable Alternative

FEP was developed as a true melt-processable alternative to PTFE, opening up a world of manufacturing possibilities.

It can be easily injection molded and extruded into complex and intricate parts. It also offers excellent clarity and resistance to UV weathering.

The primary trade-off is a lower service temperature, with a maximum continuous use temperature of around 200°C (400°F). It is also softer and less resistant to wear than PTFE.

PFA (Perfluoroalkoxy): The High-Performance Hybrid

PFA effectively combines the best attributes of both PTFE and FEP, though typically at a higher cost.

It shares the same high-temperature resistance and chemical inertness as PTFE (up to 260°C) while also being fully melt-processable like FEP. This makes it the material of choice for demanding applications requiring both extreme performance and complex geometries, such as linings for chemical processing equipment.

PFA also offers better flexibility and a longer flex-life than PTFE, making it ideal for tubing and other components that must withstand repeated movement.

ETFE (Ethylene Tetrafluoroethylene): The Tough Structural Material

ETFE is structurally different and should be considered a high-strength engineering material rather than just a non-stick coating.

While its temperature resistance is lower (around 150°C or 300°F), it possesses superior mechanical toughness, stiffness, and abrasion resistance compared to the other three. It is often sold under the brand name Tefzel®.

Because of its durability and excellent chemical resistance, ETFE is frequently used in demanding architectural applications, chemical tank linings, and wire and cable insulation where physical strength is paramount.

Understanding the Critical Trade-offs

Selecting the correct fluoropolymer requires balancing three competing factors: thermal performance, manufacturing requirements, and mechanical properties.

Temperature Resistance vs. Processability

This is the fundamental choice. If your application demands the absolute highest temperature performance and involves a simple shape, PTFE is the standard. If you need to create a complex part via injection molding, you must choose a melt-processable option like FEP for moderate temperatures or PFA for high temperatures.

Non-Stick Performance vs. Mechanical Strength

PTFE, FEP, and PFA are primarily valued for their extreme lubricity and chemical inertness. ETFE, on the other hand, sacrifices some of the thermal performance and slickness of the others for a massive increase in impact strength, rigidity, and wear resistance. It is the material you choose when durability is more important than a low-friction surface.

Cost vs. Overall Performance

There is a clear cost hierarchy tied to performance. Generally, PTFE is the most economical base resin, followed by FEP. PFA is a premium material, offering the highest combined performance (heat resistance plus processability) at a correspondingly higher price point.

Making the Right Choice for Your Application

Your final decision should be guided by the primary engineering demand of your project.

- If your primary focus is maximum heat and chemical resistance for simple shapes: Choose PTFE for its unmatched performance profile and cost-effectiveness in forms like sheets, tapes, and basic seals.

- If your primary focus is creating complex parts via molding: Select PFA for high-temperature applications or FEP as a more economical choice for services below 200°C.

- If your primary focus is mechanical toughness and durability: ETFE is the clear winner for applications requiring high tensile strength, and abrasion and radiation resistance.

Understanding these fundamental differences allows you to select the precise fluoropolymer that meets your project's unique performance and manufacturing demands.

Summary Table:

| Type | Max Continuous Temp | Key Feature | Primary Manufacturing Method |

|---|---|---|---|

| PTFE | 260°C (500°F) | Highest temp resistance, lowest friction | Compression & Sintering |

| FEP | 200°C (400°F) | Melt-processable, good clarity | Injection Molding, Extrusion |

| PFA | 260°C (500°F) | Melt-processable, high temp & chemical resistance | Injection Molding, Extrusion |

| ETFE | 150°C (300°F) | High mechanical strength, toughness | Injection Molding, Extrusion |

Struggling to choose the right fluoropolymer for your seals, liners, or labware? The experts at KINTEK can help. We specialize in the custom fabrication of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. From prototyping to high-volume production, we deliver the precision and material expertise your project demands.

Contact KINTEL today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability