To put it directly, the most significant emerging market applications for Polytetrafluoroethylene (PTFE) are in the semiconductor and advanced automobile industries. While well-known for non-stick cookware and basic industrial seals, PTFE's unique properties are now being leveraged in some of the world's most technologically demanding sectors where material failure has critical consequences.

The core takeaway is that PTFE is transitioning from a reliable commodity material into a critical enabler for high-tech innovation. Its value is no longer just in its non-stick surface, but in its extreme chemical inertness, purity, and thermal stability, which are essential for next-generation electronics, vehicles, and medical devices.

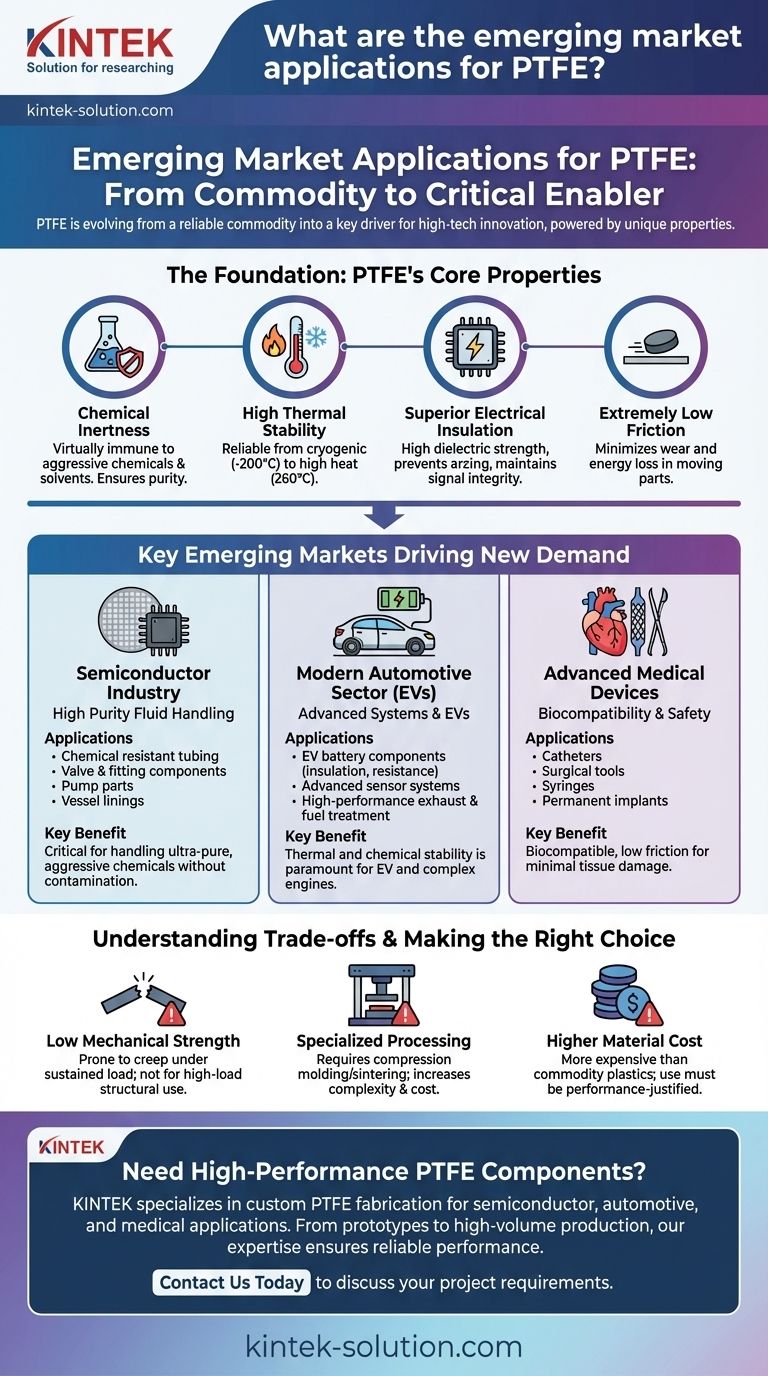

The Foundation: Why PTFE's Properties Drive New Demand

Before exploring specific markets, it's crucial to understand the fundamental properties that make PTFE so valuable. Its traditional uses in seals, gaskets, and bearings all stem from a powerful combination of traits that are now being applied in more sophisticated contexts.

### Unmatched Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals and solvents. This makes it an essential material for containing and transporting aggressive substances without risk of corrosion or contamination.

### High Thermal Stability

The material performs reliably across an exceptionally wide range of temperatures, from cryogenic applications (-200°C) to high-heat environments (up to 260°C). This stability is critical for processes involving extreme temperature fluctuations.

### Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. This property is vital for preventing electrical arcing and ensuring signal integrity in sensitive electronic components.

### Extremely Low Friction

Known as one of the most slippery materials in existence, its low coefficient of friction minimizes wear and energy loss in moving parts, making it ideal for high-performance bearings and seals.

Key Emerging Markets for PTFE

These core properties are creating new demand in sectors defined by high purity, harsh operating conditions, and extreme performance requirements.

### The Semiconductor Industry

The fabrication of microchips is an exceptionally demanding process. It involves highly corrosive chemicals and requires absolute purity to avoid contaminating the silicon wafers.

PTFE is the material of choice for components that handle these fluids, including chemical resistant tubing, valve and fitting components, pump parts, and vessel linings. Its inertness ensures the integrity of the manufacturing process.

### The Modern Automotive Sector

The automotive industry's evolution towards electric vehicles (EVs) and more complex engine systems has created new applications for PTFE.

Its role extends far beyond simple washers or seals. PTFE is now used in EV battery components for its electrical insulation and chemical resistance, in advanced sensor systems, and in high-performance exhaust gas treatment and fuel systems where heat and chemical resistance are paramount.

### Advanced Medical Devices

Biocompatibility and purity make PTFE a critical material in the medical field. It is widely used in applications that come into direct contact with the human body.

This includes life-saving devices like catheters, surgical tools, syringes, and even permanent implants. Its lubricity (low friction) is especially valuable for devices that need to be inserted with minimal tissue damage.

Understanding the Trade-offs

Despite its powerful advantages, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

### Relatively Low Mechanical Strength

Compared to engineering plastics like PEEK or Nylon, virgin PTFE is a relatively soft material. It can be prone to "creep," or deformation under a sustained load, and is not suitable for high-load structural applications without reinforcement.

### Specialized Processing Requirements

PTFE cannot be processed using conventional melt techniques like injection molding. It requires specialized methods like compression molding and sintering, which can increase manufacturing complexity and cost.

### Higher Material Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than common commodity plastics. Its use must be justified by a clear performance requirement that other materials cannot meet.

Making the Right Choice for Your Application

Selecting the right material requires aligning its capabilities with your primary engineering goal.

- If your primary focus is high-purity fluid handling: PTFE is the industry standard for semiconductor and aggressive chemical processing where contamination is not an option.

- If your primary focus is high-performance automotive components: Explore PTFE for applications in EV systems, advanced sensors, and fuel/exhaust components that demand thermal and chemical stability.

- If your primary focus is biocompatibility and safety: PTFE's proven track record makes it a default choice for critical medical devices, implants, and food-grade processing equipment.

Ultimately, understanding where PTFE is heading allows you to make more strategic material decisions for the next generation of products.

Summary Table:

| Key Property | Why It Matters for Emerging Markets |

|---|---|

| Chemical Inertness | Essential for handling ultra-pure, aggressive chemicals in semiconductor fabs without contamination. |

| High Thermal Stability | Enables performance in extreme temperatures from cryogenics to high heat in EV batteries and sensors. |

| Electrical Insulation | Critical for preventing arcing and ensuring signal integrity in sensitive microelectronics. |

| Biocompatibility & Low Friction | Vital for medical implants and devices requiring minimal tissue damage and proven safety. |

Need High-Performance PTFE Components for Demanding Applications?

As the demand for PTFE grows in the semiconductor, automotive, and medical industries, precision manufacturing becomes critical. At KINTEK, we specialize in fabricating custom PTFE components—from seals and liners to complex labware—that meet the stringent purity, thermal, and chemical resistance requirements of these advanced sectors.

Whether you're developing next-generation microchips, EV battery systems, or life-saving medical devices, our expertise ensures your components perform reliably where failure is not an option.

Contact us today to discuss your project requirements—from prototypes to high-volume production—and leverage our precision manufacturing capabilities for your most critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability