At their core, the primary disadvantages of Teflon encapsulated O-rings stem from their hybrid construction. The protective Teflon jacket, while providing excellent chemical resistance, is physically fragile and prone to scratches or damage in abrasive environments, which can compromise the entire seal. Furthermore, they are more expensive than alternatives and possess specific chemical and thermal limitations that make them unsuitable for certain aggressive applications.

While Teflon encapsulated O-rings uniquely combine chemical inertness with flexibility, their main weakness is the vulnerability of their thin outer jacket. A breach in this jacket exposes the less-resistant inner core, leading to seal failure.

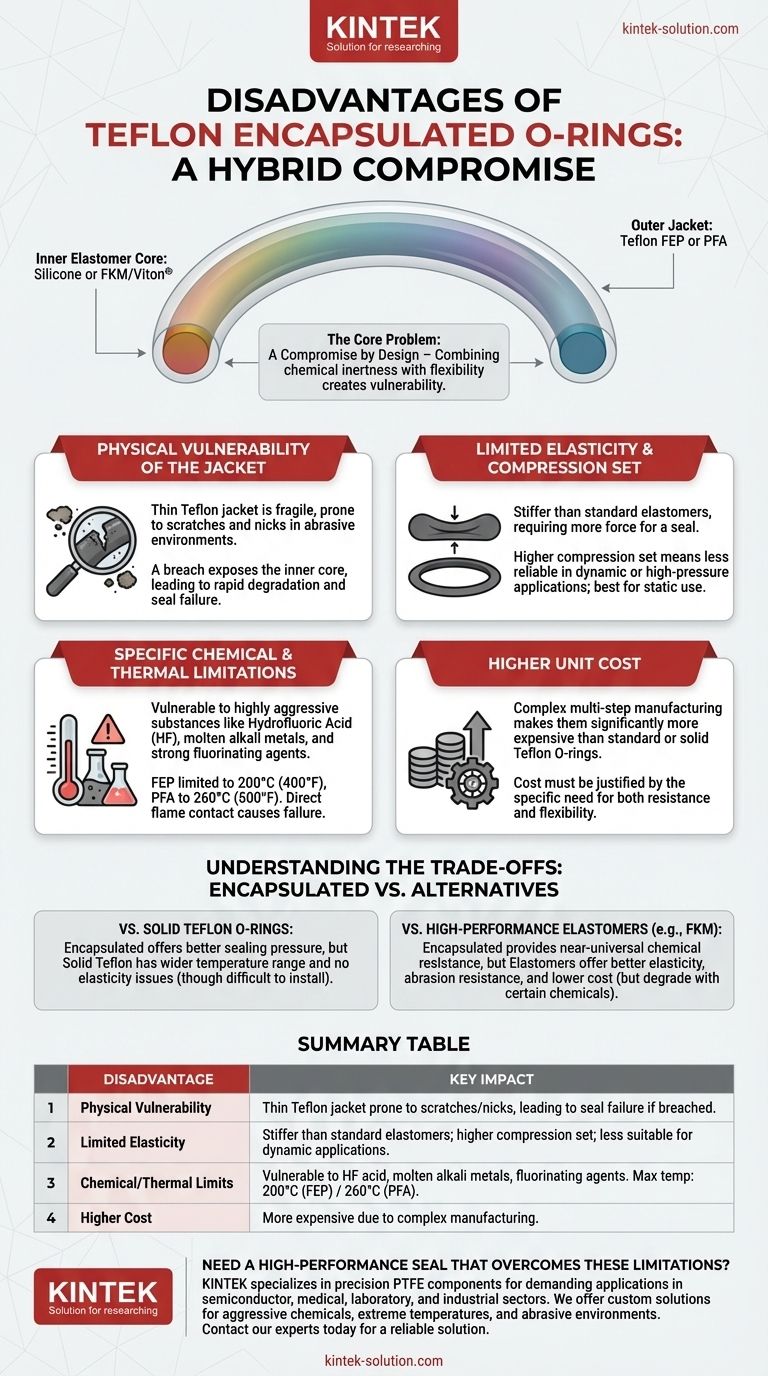

The Core Problem: A Compromise by Design

Teflon encapsulated O-rings are a composite seal. They consist of an inner elastomeric core, typically made of Silicone or FKM (Viton®), which is seamlessly enclosed within an outer jacket of Teflon FEP or PFA.

This design aims to deliver the best of both worlds: the superior chemical resistance of Teflon and the flexibility and memory of an elastomer. However, the disadvantages are a direct result of this compromised structure.

Key Disadvantages Explained

Physical Vulnerability of the Jacket

The thin Teflon jacket is the O-ring's first line of defense, but it is also its primary point of failure. It is susceptible to scratching, nicks, and damage, especially in applications with abrasive media or rough sealing surfaces.

Once the jacket is breached, the aggressive media can attack the inner elastomeric core, causing it to swell or degrade rapidly and leading to a complete loss of sealing integrity.

Limited Elasticity and Compression Set

While far more flexible than a solid Teflon O-ring, an encapsulated ring is still stiffer than a standard elastomer O-ring. This reduced elasticity means it requires more force to create an effective seal.

They also exhibit a higher compression set, meaning they are less able to return to their original shape after being compressed. This makes them best suited for static or semi-dynamic applications and less reliable in highly dynamic or high-pressure situations.

Specific Chemical and Thermal Limitations

Despite Teflon's reputation for being nearly inert, encapsulated O-rings are not universally resistant. They are vulnerable to a few highly aggressive substances.

They should not be used with hydrofluoric acid (HF), molten alkali metals like sodium, or extremely strong fluorinating agents.

Furthermore, they have clear temperature ceilings. The FEP jacket is generally limited to 200°C (400°F), and the more robust PFA jacket is limited to 260°C (500°F). Direct flame contact will cause immediate failure.

Higher Unit Cost

The complex, multi-step manufacturing process required to seamlessly encapsulate the core makes these O-rings significantly more expensive than both standard elastomer O-rings and solid Teflon O-rings.

This cost must be justified by the specific need for both chemical resistance and flexibility in an application where a standard seal would fail.

Understanding the Trade-offs: Encapsulated vs. Alternatives

Choosing the right seal requires understanding its limitations relative to other options. The decision often comes down to a trade-off between physical durability, chemical resistance, and cost.

Against Solid Teflon O-Rings

A solid Teflon O-ring offers a wider temperature range and is made of a single, homogenous material. However, it has virtually no elasticity, making it difficult to install and prone to leaking in applications with thermal cycling or pressure variations. The encapsulated O-ring is a superior choice for reliable sealing pressure.

Against High-Performance Elastomers

A standard O-ring made from materials like FKM or FFKM offers excellent elasticity, abrasion resistance, and a much lower cost. However, it will not have the near-universal chemical resistance of a Teflon jacket. If the application involves chemicals that would degrade FKM, the encapsulated ring is the necessary choice.

Making the Right Choice for Your Application

Your final decision must be aligned with the specific demands of the operating environment.

- If your primary focus is sealing aggressive chemicals in a static application: A Teflon encapsulated O-ring is an excellent choice, provided the specific chemical and temperature limits are respected.

- If your application involves abrasive media or dynamic movement: A high-performance elastomer like FKM may offer better reliability and a longer service life at a lower cost.

- If your primary focus is cost savings in a non-aggressive environment: A standard elastomer O-ring is the most practical and economical solution.

- If you need extreme temperature resistance above 260°C: You must explore other materials, as solid Teflon O-rings present significant sealing challenges due to their rigidity.

Ultimately, selecting the correct seal means accurately matching the specific weaknesses of the O-ring to the known hazards of your application.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Physical Vulnerability | Thin Teflon jacket is prone to scratches and nicks, leading to seal failure if breached. |

| Limited Elasticity | Stiffer than standard elastomers; higher compression set; less suitable for dynamic applications. |

| Chemical/Thermal Limits | Vulnerable to HF acid, molten alkali metals, and fluorinating agents. Max temp: 200°C (FEP) / 260°C (PFA). |

| Higher Cost | More expensive than standard elastomer or solid Teflon O-rings due to complex manufacturing. |

Need a High-Performance Seal That Overcomes These Limitations?

Choosing the right sealing component is critical for the reliability and safety of your equipment. At KINTEK, we specialize in manufacturing precision PTFE components (including seals, liners, and custom labware) for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We understand the trade-offs involved in seal selection. Whether you need a custom solution to handle aggressive chemicals, extreme temperatures, or abrasive environments, our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly matched to your operational needs.

Don't let a compromised seal risk your process. Contact our experts today for a consultation on a reliable, high-performance solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech