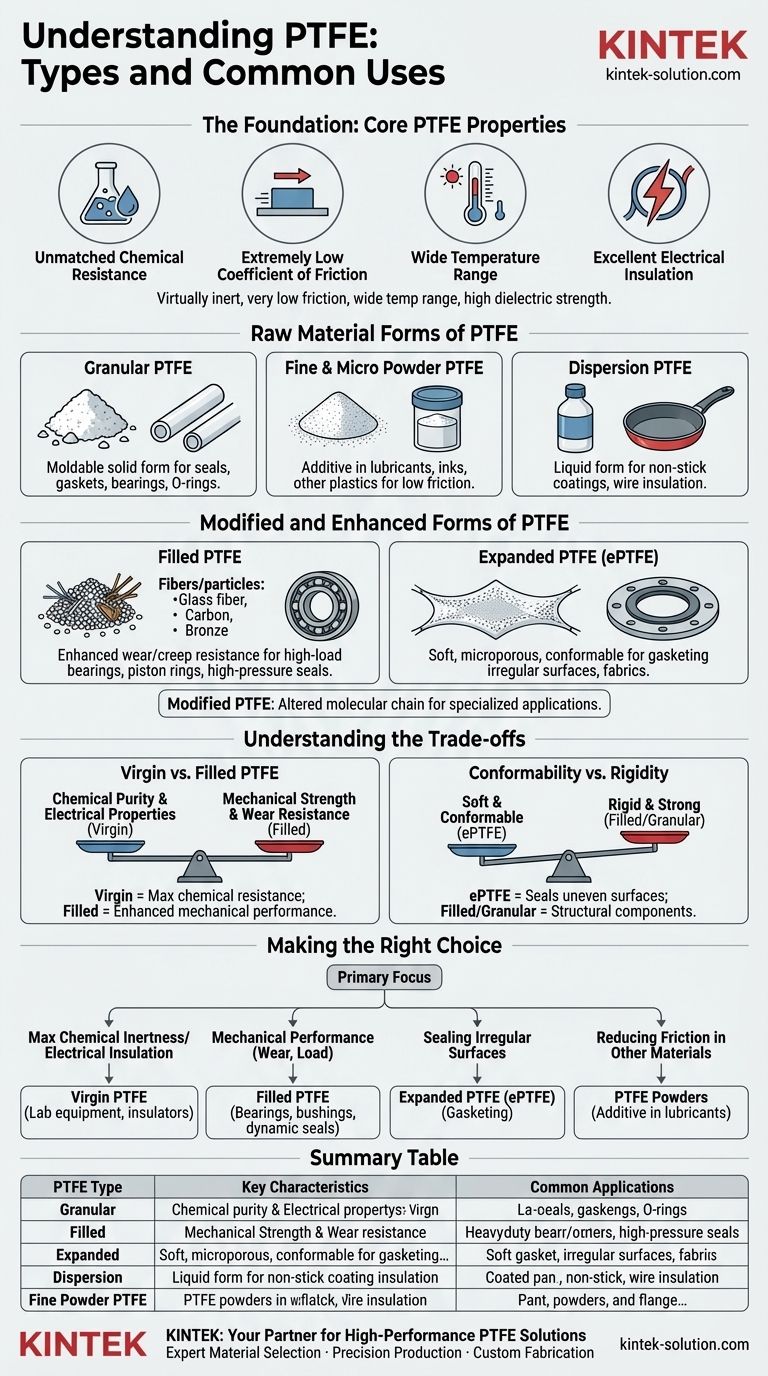

At its core, Polytetrafluoroethylene (PTFE) is not a single material but a family of polymers. The primary types are distinguished by their physical form and whether they have been modified with fillers. These include granular PTFE for molding solid parts, fine powders for use as additives, dispersions for creating non-stick coatings, filled PTFE for enhanced mechanical strength, and expanded PTFE for gasketing.

The key is to understand that while all PTFE variants share core properties like extreme chemical resistance and low friction, the specific form or modification you choose is what tailors the material for a specific engineering challenge—from a simple O-ring to a high-wear industrial bearing.

The Foundation: Core PTFE Properties

Before examining the different types, it's essential to understand the properties that make PTFE a unique and valuable engineering material.

### Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes it an ideal choice for seals, linings, and components used in aggressive chemical processing.

### Extremely Low Coefficient of Friction

With a coefficient of friction around 0.05, PTFE is one of the slipperiest solid materials known. This property is the reason it is used for non-stick coatings and self-lubricating bearings.

### Wide Temperature Range

PTFE maintains its properties over a very wide temperature range, making it suitable for both cryogenic applications and high-temperature environments.

### Excellent Electrical Insulation

It is an excellent electrical insulator with high dielectric strength, making it valuable in electronics and electrical wiring.

Raw Material Forms of PTFE

The most fundamental way to categorize PTFE is by its unprocessed, raw form. This form dictates how it can be turned into a final product.

### Granular PTFE

This is the workhorse of the PTFE family. Produced as a powder with larger particles, it is the primary raw material for molding solid shapes like rods, sheets, and tubes.

These basic shapes are then machined into finished components such as seals, gaskets, bearings, bushings, and O-rings.

### Fine & Micro Powder PTFE

These powders have much smaller particles and are not typically molded on their own. Instead, they are used as an additive.

They are blended into other materials like lubricants, greases, inks, and even other plastics to impart PTFE's low-friction characteristics to the host material.

### Dispersion PTFE

This is a milky-white aqueous dispersion of tiny PTFE particles. This liquid form is used to create coatings.

The most well-known application is for non-stick surfaces on cookware, but it is also used for industrial coatings on wires, fabrics, and other components requiring a thin, low-friction layer.

Modified and Enhanced Forms of PTFE

To overcome some of the inherent weaknesses of pure PTFE, it is often modified or processed in special ways to enhance its performance.

### Filled PTFE

This is one of the most common and important modifications. Fillers are blended with granular PTFE before molding to dramatically improve its mechanical properties.

Common fillers include glass fiber, carbon, graphite, bronze, and PEEK. These additives increase wear resistance, reduce creep (cold flow under pressure), and improve thermal conductivity. This makes filled PTFE ideal for demanding applications like bearings, piston rings, and high-pressure seals.

### Expanded PTFE (ePTFE)

Expanded PTFE is created by rapidly stretching pure PTFE under specific conditions. This process creates a strong, microporous material that is soft and highly conformable.

Its primary use is in gasketing and sealing, especially on irregular, damaged, or fragile flange surfaces where a standard rigid gasket would fail. It is also used in medical implants and high-performance fabrics.

### Modified PTFE

This refers to a PTFE polymer where the molecular chain has been slightly altered. These modifications can result in a material with reduced porosity, better weldability, and improved resistance to permeation, suiting it for specialized chemical and semiconductor applications.

Understanding the Trade-offs

Choosing the right PTFE type involves balancing its inherent strengths against its weaknesses and the specific demands of your application.

### Virgin vs. Filled PTFE

The primary trade-off is between chemical purity and mechanical strength. Virgin (unfilled) PTFE offers the highest chemical resistance and best electrical properties.

However, it suffers from poor mechanical performance, particularly creep, where it deforms under a sustained load. Filled PTFE solves this mechanical weakness but may have slightly reduced chemical resistance and will lose the exceptional electrical insulation properties of virgin PTFE.

### Conformability vs. Rigidity

Expanded PTFE is exceptionally soft and conformable, making it a superior sealant for uneven surfaces. However, it lacks the rigidity and strength for use as a structural or load-bearing component.

Conversely, a solid gasket made from filled PTFE is rigid and strong but will not seal effectively on a damaged flange.

### Cost and Complexity

As you move from standard granular PTFE to filled, expanded, or modified versions, the cost and complexity of manufacturing increase. The performance gains must justify the added expense.

Making the Right Choice for Your Goal

Your final selection depends entirely on the most critical performance requirement for your component.

- If your primary focus is maximum chemical inertness or electrical insulation: Virgin (unfilled) PTFE is the correct choice for applications like lab equipment or high-frequency insulators.

- If your primary focus is mechanical performance (wear, load, or creep resistance): Filled PTFE is essential for demanding components like bearings, bushings, and dynamic seals.

- If your primary focus is sealing irregular or fragile surfaces: Expanded PTFE (ePTFE) provides the necessary conformability for creating a reliable gasket.

- If your primary focus is reducing friction in another material: PTFE powders (fine or micro) are the right option to use as an additive in lubricants or other polymers.

Ultimately, selecting the correct PTFE means matching the specific material type to the unique mechanical and environmental demands of your application.

Summary Table:

| PTFE Type | Key Characteristics | Common Applications |

|---|---|---|

| Granular PTFE | Moldable solid form | Seals, gaskets, O-rings, bushings |

| Filled PTFE | Enhanced wear/creep resistance | High-load bearings, piston rings, seals |

| Expanded PTFE (ePTFE) | Soft, microporous, conformable | Gasketing for irregular surfaces, fabrics |

| Dispersion PTFE | Liquid form for coatings | Non-stick surfaces, wire insulation |

| Fine Powder PTFE | Additive for friction reduction | Lubricants, inks, plastics |

Need a Custom PTFE Component?

Understanding the different types of PTFE is the first step. The next is finding a partner who can precisely manufacture the component you need. At KINTEK, we specialize in fabricating high-performance PTFE parts—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Expert Material Selection: Guidance on choosing virgin, filled, or expanded PTFE for your specific mechanical, chemical, and thermal requirements.

- Precision Production: Machining and molding of components that meet exact specifications for critical applications.

- Custom Fabrication: Support from initial prototypes to high-volume production runs.

Let us help you solve your engineering challenge with the right PTFE solution. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers