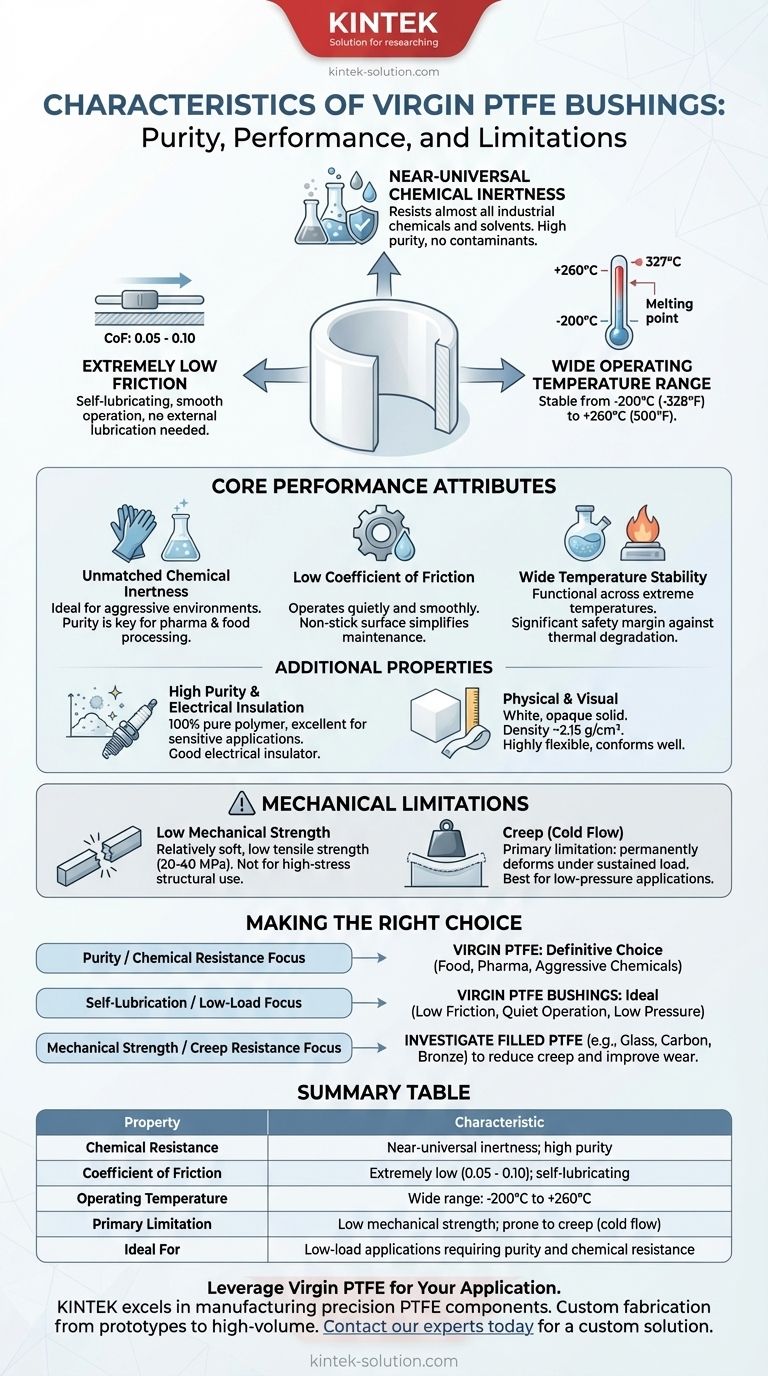

At its core, a virgin PTFE bushing is defined by three exceptional characteristics: an extremely low coefficient of friction, near-universal chemical inertness, and a remarkably wide operating temperature range. It is a pure, unfilled polymer prized for its unique combination of thermal, chemical, and non-stick properties.

Virgin PTFE is the ideal material for low-load, self-lubricating applications where purity and resistance to chemicals or extreme temperatures are paramount. However, its primary limitation is its mechanical softness and its tendency to deform under a sustained load, a behavior known as creep.

The Core Performance Characteristics

To understand if virgin PTFE is the right choice, you must first appreciate its elite performance attributes. These properties make it a go-to material in demanding industries like pharmaceuticals, food processing, and chemical engineering.

Unmatched Chemical Inertness

Virgin PTFE is almost completely inert, resisting nearly all industrial chemicals and solvents. This makes it invaluable for components that will be exposed to aggressive or corrosive substances.

Its high purity, with no fillers or additives, ensures that it will not contaminate the materials it comes into contact with.

Extremely Low Coefficient of Friction

With a coefficient of friction between 0.05 and 0.10, virgin PTFE is one of the most slippery solid materials known. This allows bushings to operate smoothly and quietly without external lubrication.

This self-lubricating, non-stick surface requires minimal maintenance and prevents other materials from adhering to it, simplifying cleaning and preventing contamination.

Wide Operating Temperature Range

Virgin PTFE maintains its properties across an exceptionally broad temperature spectrum. It remains stable and functional for continuous service from -200°C (-328°F) up to +260°C (500°F).

While its functional limit is 260°C, its actual melting point is significantly higher, around 327°C (621°F), providing a substantial margin of safety against thermal degradation.

High Purity and Electrical Insulation

Being 100% pure polymer, virgin PTFE is a preferred material for applications where contamination is a critical concern, such as in semiconductor manufacturing or medical devices.

It is also an excellent electrical insulator, making it useful for isolating components in electronic assemblies.

Understanding the Mechanical Limitations

While its performance characteristics are impressive, virgin PTFE's primary trade-offs are mechanical. Understanding these limitations is critical to avoid misapplication and component failure.

Low Mechanical Strength

Virgin PTFE is a relatively soft material with a low tensile strength, typically between 20-40 MPa (2900-5800 psi). It is not designed for high-stress, structural applications.

Its high elongation at break (200-500%) is a measure of its excellent flexibility, but this is directly related to its softness.

The Problem of Creep (Cold Flow)

This is the most significant limitation of virgin PTFE. Creep, or cold flow, is the tendency of the material to slowly and permanently deform when subjected to a constant compressive load.

Under pressure, a virgin PTFE bushing can gradually change shape, losing its precise dimensions and potentially causing the assembly to fail. This is why it is best suited for low-pressure applications.

Key Physical and Visual Properties

Beyond its core performance, several physical properties define virgin PTFE.

Appearance and Density

In its virgin state, PTFE is characteristically a white, opaque solid.

It has a density of approximately 2.15 g/cm³.

High Flexibility

As indicated by its high elongation percentage, virgin PTFE is a highly flexible material. This allows it to conform well to surfaces and absorb some vibration.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is purity or chemical resistance: Virgin PTFE is the definitive choice for food, pharmaceutical, or aggressive chemical environments where contamination is unacceptable.

- If your primary focus is self-lubrication in a low-load system: Virgin PTFE bushings are ideal for applications that require low friction and quiet operation without significant or sustained pressure.

- If your primary focus is mechanical strength or resistance to deformation: You should investigate filled PTFE grades (e.g., glass, carbon, or bronze-filled), which are specifically engineered to drastically reduce creep and improve wear resistance.

By understanding both its unparalleled performance and its distinct mechanical weaknesses, you can leverage virgin PTFE effectively in the applications where it truly excels.

Summary Table:

| Property | Characteristic |

|---|---|

| Chemical Resistance | Near-universal inertness; high purity |

| Coefficient of Friction | Extremely low (0.05 - 0.10); self-lubricating |

| Operating Temperature | Wide range: -200°C to +260°C |

| Primary Limitation | Low mechanical strength; prone to creep (cold flow) |

| Ideal For | Low-load applications requiring purity and chemical resistance |

Leverage the unique properties of virgin PTFE for your application

Virgin PTFE bushings are the ideal solution for semiconductor, medical, and laboratory applications where chemical purity, non-stick performance, and thermal stability are non-negotiable.

KINTEK excels in manufacturing precision PTFE components. We specialize in custom fabrication—from prototypes to high-volume orders—ensuring your bushings, seals, and labware meet exact specifications for performance and purity.

Ready to solve your unique engineering challenge? Contact our experts today to discuss your project and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability