For demanding rotary applications, virgin Polytetrafluoroethylene (PTFE) offers a unique combination of performance characteristics that standard elastomeric seals cannot match. It is specified for its exceptionally low friction, unparalleled chemical inertness, and ability to perform reliably across extreme temperature and pressure ranges. This ensures longer service life and reduced maintenance in the most challenging operational environments.

While traditional rubber seals are common, virgin PTFE is the material of choice for applications where high speeds, aggressive chemicals, or extreme temperatures would cause conventional seals to degrade and fail. Its core benefit is reliability under conditions that are simply outside the operating window of other materials.

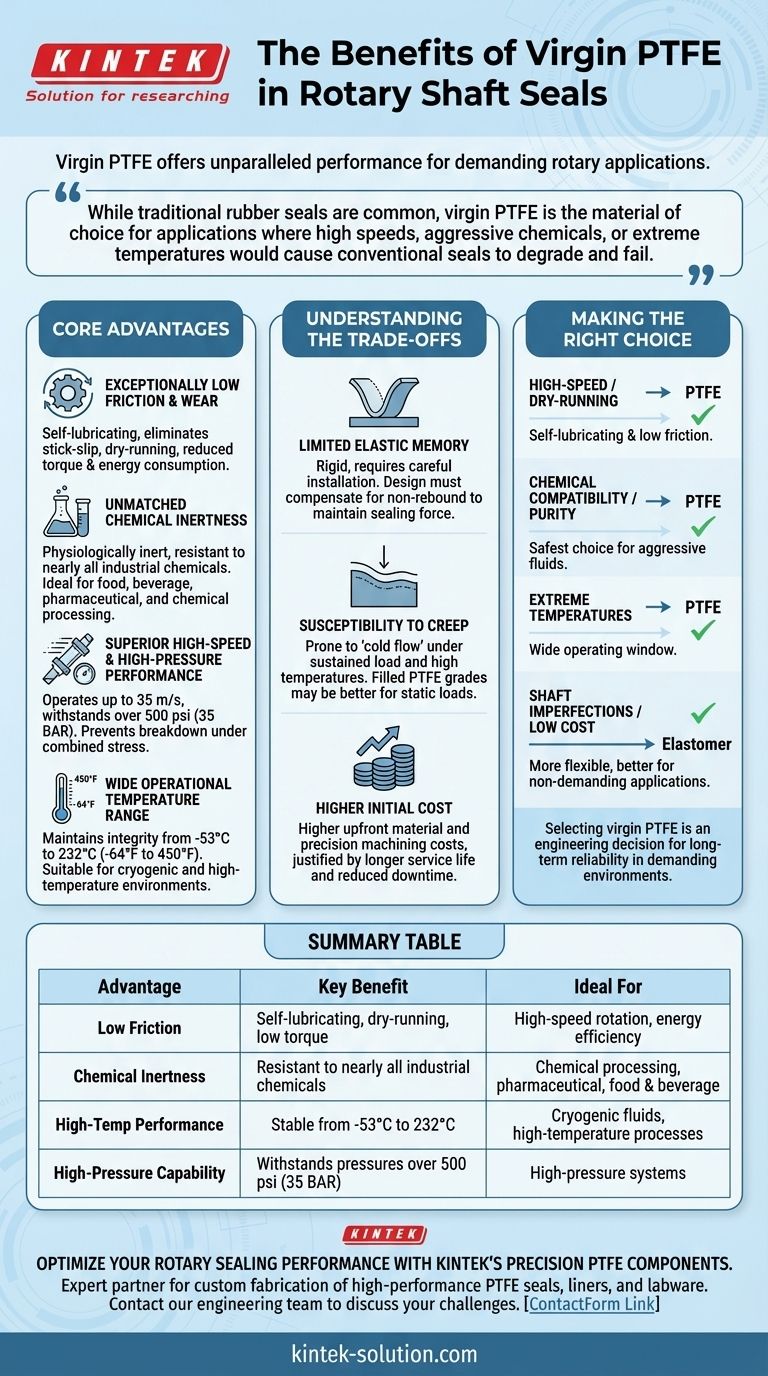

Core Advantages of Virgin PTFE in Sealing

Exceptionally Low Friction and Wear

Virgin PTFE possesses one of the lowest coefficients of friction of any solid material. This self-lubricating property is critical in rotary applications.

It eliminates "stick-slip" behavior, ensuring smooth rotation from a complete stop with very low breakout friction. This quality allows for dry-running capabilities, reduces wear on the mating shaft, and generates significantly less torque, which lowers energy consumption.

Unmatched Chemical Inertness

Often called the "king of plastic," PTFE is physiologically inert and resistant to nearly all industrial chemicals and aggressive fluids.

This makes it the default choice for equipment in chemical processing, pharmaceutical, and food and beverage industries, where seal material must not react with or contaminate the process medium.

Superior High-Speed and High-Pressure Performance

Compared to traditional elastomeric lip seals, PTFE seals can operate at much higher rotational velocities (up to 35 m/s) and withstand significantly higher pressures (over 500 psi / 35 BAR).

The material's stability prevents it from breaking down or extruding under the combined stresses of high speed and pressure, which is a common failure point for rubber-based seals.

Wide Operational Temperature Range

Virgin PTFE maintains its integrity and sealing performance across an exceptionally broad temperature spectrum, typically from -64°F to 450°F (-53°C to 232°C).

This allows it to be used in applications involving cryogenic fluids or high-temperature processing where elastomers would become brittle or degrade rapidly.

Understanding the Trade-offs

Limited Elastic Memory

Virgin PTFE is a rigid plastic and lacks the elastic memory of rubber. This means it will not rebound to its original shape as effectively after being deformed.

Careful installation is required to avoid damaging the seal lip, and its design must compensate for this rigidity to maintain a consistent sealing force against the shaft.

Susceptibility to Creep

Under sustained compressive load and elevated temperatures, virgin PTFE can be prone to "cold flow" or creep, where the material slowly deforms over time.

While high-quality seal design accounts for this, it is a factor that makes filled PTFE grades a better choice for applications with high static loads.

Higher Initial Cost

The raw material and precision machining required for PTFE seals typically result in a higher upfront cost compared to standard molded elastomeric seals.

However, this initial investment is often justified by reduced maintenance, less downtime, and longer service life in demanding applications where other materials would fail prematurely.

Making the Right Choice for Your Application

Choosing the right seal material requires matching its properties to the primary demands of your system.

- If your primary focus is high-speed rotation or dry-running conditions: PTFE's self-lubricating properties and low friction coefficient are its most significant advantages.

- If your primary focus is chemical compatibility or purity: PTFE's inertness makes it the safest choice for sealing aggressive fluids or for food, beverage, and pharmaceutical applications.

- If your primary focus is extreme temperatures: PTFE's wide operating window ensures seal integrity where standard elastomers would become brittle or melt.

- If your primary focus is managing shaft imperfections or a low-cost solution: A more flexible elastomeric seal may be a more suitable choice for non-demanding, general-purpose applications.

Ultimately, selecting virgin PTFE is an engineering decision to prioritize long-term reliability and performance in environments that push beyond the limits of conventional materials.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Low Friction | Self-lubricating, dry-running, low torque | High-speed rotation, energy efficiency |

| Chemical Inertness | Resistant to nearly all industrial chemicals | Chemical processing, pharmaceutical, food & beverage |

| High-Temp Performance | Stable from -53°C to 232°C (-64°F to 450°F) | Cryogenic fluids, high-temperature processes |

| High-Pressure Capability | Withstands pressures over 500 psi (35 BAR) | High-pressure systems |

Optimize your rotary sealing performance with KINTEK's precision PTFE components.

If your application demands the superior reliability, chemical resistance, and extreme temperature performance of virgin PTFE, KINTEK is your expert partner. We specialize in the custom fabrication of high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to ensure your components meet the strictest requirements, offering everything from prototypes to high-volume orders. Let us help you extend service life and reduce maintenance costs.

Contact our engineering team today to discuss your specific sealing challenges and receive a customized solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability