Combining Teflon with fiberglass creates a high-performance composite material that marries the structural strength of glass fibers with the extreme resilience of a fluoropolymer coating. This process results in a material that is not only strong but also exceptionally resistant to moisture, chemicals, UV radiation, and degradation over time.

The fundamental benefit is synergy: fiberglass provides a robust, high-strength structural core, while the Teflon (PTFE) coating acts as an impenetrable shield against environmental and chemical attacks, creating a material far more durable than its individual components.

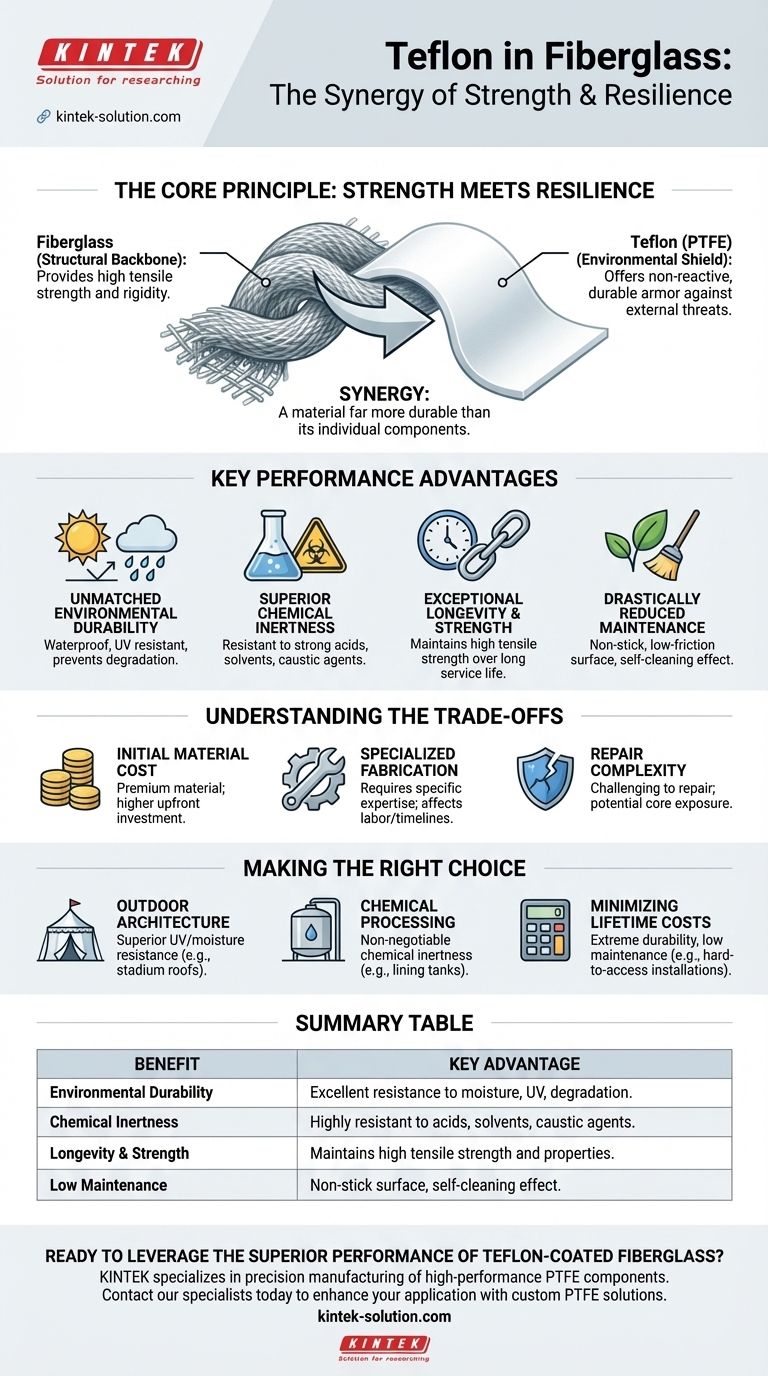

The Core Principle: Strength Meets Resilience

To understand the benefits, it's essential to see this not as a simple mixture, but as a strategic combination of two distinct materials, each compensating for the other's weaknesses.

The Role of Fiberglass

Fiberglass serves as the structural backbone of the composite. It provides the material with its rigidity and, most importantly, its high tensile strength, which is the ability to withstand being pulled apart without breaking.

The Role of Teflon (PTFE)

Teflon, the brand name for Polytetrafluoroethylene (PTFE), provides an environmental shield. On its own, PTFE is not particularly strong, but it is one of the most non-reactive and durable substances known. It armors the fiberglass core against external threats.

Key Performance Advantages Explained

The synergy between these two materials delivers a unique set of advantages that make it suitable for demanding industrial and architectural applications.

Unmatched Environmental Durability

The Teflon coating makes the material virtually waterproof, preventing moisture from degrading the underlying glass fibers. It is also exceptionally resistant to UV radiation, which means it won't yellow, weaken, or become brittle even after years of direct sun exposure.

Superior Chemical Inertness

This composite is a preferred material in chemical processing environments. The PTFE shield is highly resistant to a wide range of aggressive chemicals, including strong acids, solvents, and caustic agents, protecting equipment like tanks and pipes from corrosion and failure.

Exceptional Longevity and Strength

The combination of a strong core and a protective shield results in a material with a very long service life. It maintains its high tensile strength and physical properties over time, even in harsh conditions, preventing costly replacement and downtime.

Drastically Reduced Maintenance

The surface of Teflon is famously non-stick and low-friction. This property means that dirt, pollutants, and other contaminants do not easily adhere to it. In many applications, this translates to a self-cleaning effect from rainfall, eliminating the need for regular maintenance.

Understanding the Trade-offs

While the benefits are significant, it's critical to understand the associated considerations for any project.

Initial Material Cost

Teflon-coated fiberglass is a premium, high-performance material. Its initial cost is higher than standard fiberglass or other conventional building materials. The investment is justified by its extended lifespan and low maintenance requirements.

Specialized Fabrication

Working with this composite requires specific expertise. The material cannot be handled or fabricated in the same way as traditional textiles or plastics. This can impact project timelines and labor costs if specialized contractors are needed.

Repair Complexity

While incredibly durable, damage to the Teflon coating can be challenging to repair in the field. A breach in the protective layer could potentially expose the fiberglass core, compromising the material's long-term integrity if not addressed properly.

Making the Right Choice for Your Application

Selecting this material depends entirely on whether its unique advantages align with your project's primary goals.

- If your primary focus is longevity in outdoor architecture: The superior UV and moisture resistance makes it the definitive choice for tensile fabric structures like stadium roofs or canopies.

- If your primary focus is reliability in chemical processing: Its chemical inertness is non-negotiable for lining tanks, pipes, and gaskets where corrosion prevention is critical.

- If your primary focus is minimizing lifetime operational costs: The extreme durability and low-to-no maintenance requirements can deliver a lower total cost of ownership in critical, hard-to-access installations.

Ultimately, choosing Teflon-coated fiberglass is an investment in unparalleled durability for applications where failure is not an option.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Environmental Durability | Excellent resistance to moisture, UV radiation, and degradation. |

| Chemical Inertness | Highly resistant to strong acids, solvents, and caustic agents. |

| Longevity & Strength | Maintains high tensile strength and properties over a long service life. |

| Low Maintenance | Non-stick, low-friction surface offers a self-cleaning effect. |

Ready to leverage the superior performance of Teflon-coated fiberglass in your project?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom fabrications for composite materials. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get a solution built for durability and reliability.

Contact our specialists today to discuss how we can enhance your application with our custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials