The primary benefit of an antistatic PTFE shovel is its ability to prevent electrostatic discharge (ESD). This critical safety feature mitigates the risk of a static spark, which can be extremely hazardous in laboratory or industrial environments where flammable powders, solvents, or sensitive electronics are present.

Choosing an antistatic tool is not about convenience; it is a fundamental safety decision. The core benefit is the prevention of a static spark that could otherwise ignite flammable materials or damage sensitive components.

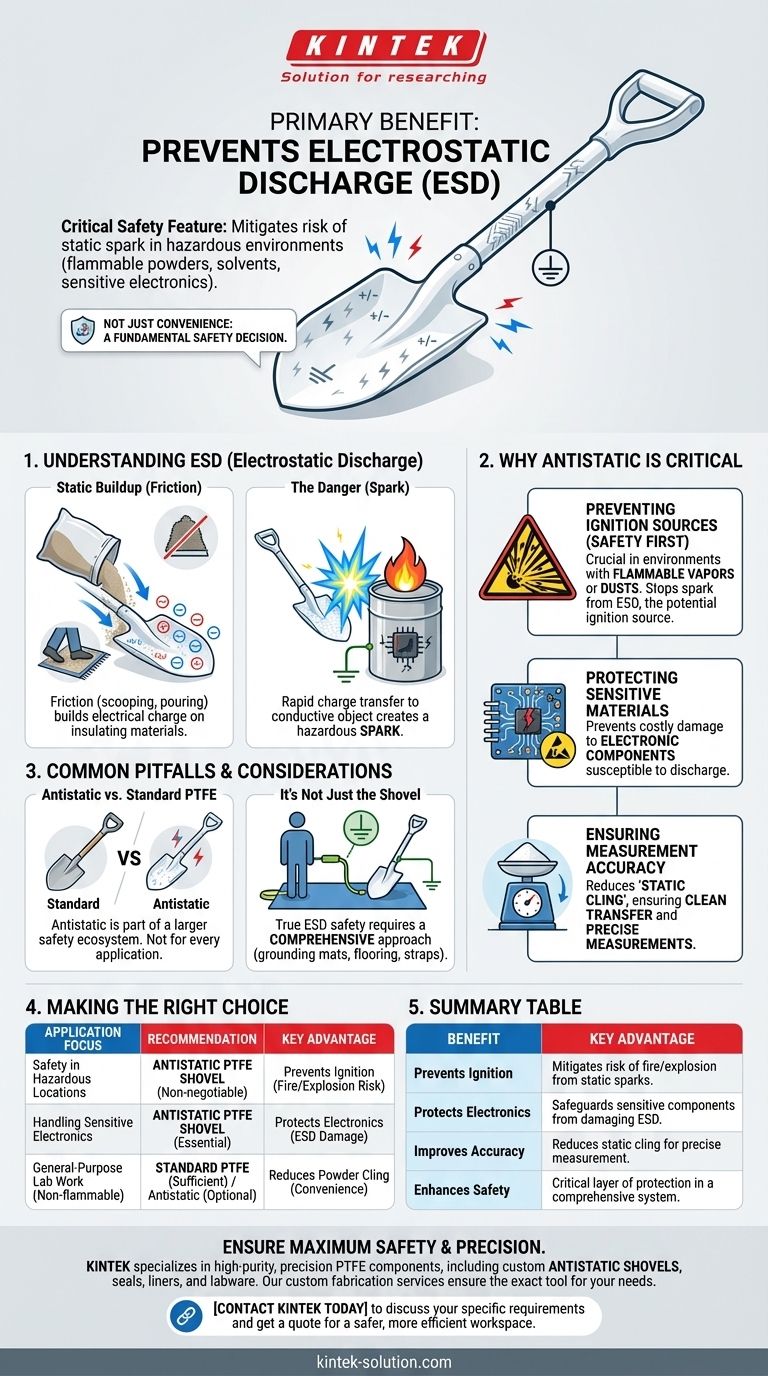

Understanding Electrostatic Discharge (ESD)

To grasp the importance of the antistatic property, we must first understand the risk it neutralizes: electrostatic discharge, or ESD.

The Science of Static Buildup

Almost any movement, such as scooping, pouring, or mixing fine powders, involves friction. This friction can cause an electrical charge to build up on the surface of an insulating material like standard plastic or even regular PTFE.

This is the same principle as shuffling your feet on a carpet and building up a static charge.

The Danger of the Spark

When a charged object gets close to a conductive object at a different potential (like a metal container or a grounded person), the charge will jump across the gap to equalize. This rapid transfer of electricity is the spark you see and feel, known as an ESD event.

Why Antistatic Properties are Critical

In a controlled environment, an uncontrolled spark is more than just a nuisance; it's a significant hazard. The antistatic material in the shovel is designed to safely dissipate static charge before it can accumulate to a dangerous level.

Preventing Ignition Sources

The single most important benefit is safety. In environments containing flammable solvent vapors or fine combustible dusts (like flour, sugar, or certain chemical powders), a tiny spark from ESD can be the ignition source for a fire or explosion.

Antistatic shovels are engineered to prevent that initial spark from ever happening.

Protecting Sensitive Materials

Beyond ignition risks, many electronic components are highly susceptible to damage from even a small electrostatic discharge. Using an antistatic shovel when handling sensitive powders or components for electronics manufacturing prevents costly damage.

Ensuring Measurement Accuracy

A secondary but significant benefit is operational precision. Static charge causes fine powders to cling to the surface of a standard shovel, leading to inaccurate measurements and material waste.

The antistatic property reduces this "static cling," ensuring that more of your material is transferred cleanly and measured accurately.

Common Pitfalls and Considerations

While invaluable, the antistatic feature is part of a larger safety ecosystem. Understanding its context is key to using it effectively.

Antistatic vs. Standard PTFE

For many applications involving non-flammable liquids or coarse granules, a standard PTFE shovel with its excellent chemical resistance and non-stick surface is perfectly adequate. The antistatic feature is specifically for environments with an identified ESD risk.

It's Not Just the Shovel

Relying solely on an antistatic shovel is a common mistake. True ESD safety requires a comprehensive approach, including grounding mats for work surfaces, appropriate flooring, and personal grounding straps for operators. The shovel is one critical component in this system.

Making the Right Choice for Your Application

Select your tool based on a clear-eyed assessment of the risks and requirements of your specific task.

- If your primary focus is safety in hazardous locations: An antistatic PTFE shovel is non-negotiable to prevent the ignition of flammable dusts or vapors.

- If your primary focus is handling sensitive electronics: The antistatic property is essential to protect components from damaging electrostatic discharge.

- If your primary focus is general-purpose lab work with non-flammable materials: Standard PTFE is often sufficient, though an antistatic model can still reduce the annoyance of powder cling.

Ultimately, choosing an antistatic PTFE shovel is a proactive investment in the safety, precision, and integrity of your work.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Prevents Ignition | Mitigates risk of fire/explosion from static sparks in flammable environments. |

| Protects Electronics | Safeguards sensitive components from damaging electrostatic discharge (ESD). |

| Improves Accuracy | Reduces static cling for precise powder measurement and transfer. |

| Enhances Safety | Provides a critical layer of protection in a comprehensive ESD safety system. |

Ensure maximum safety and precision in your operations. The primary benefit of an antistatic PTFE shovel is preventing dangerous electrostatic discharge (ESD) that can ignite flammable materials or damage sensitive electronics. At KINTEK, we specialize in manufacturing high-purity, precision PTFE components—including custom antistatic shovels, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact tool you need to protect your processes and personnel.

Contact KINTEK today to discuss your specific requirements and get a quote for a safer, more efficient workspace.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Scrapers and Shovels for Demanding Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability