The primary benefits of Polytetrafluoroethylene (PTFE) with a carbon-graphite fill are its excellent wear resistance, low friction, and high chemical compatibility, especially in demanding, fluid-based applications. This composite material is engineered to overcome the mechanical weaknesses of virgin PTFE, offering a robust solution for dynamic seals and bearings that operate in wet or humid conditions while remaining gentle on mating metal surfaces.

The crucial takeaway is that carbon-graphite filled PTFE is not just a general-purpose wear material; it is a specialized compound optimized for dynamic applications in fluid media. It provides a unique balance of durability and low friction without damaging the expensive hardware it interacts with.

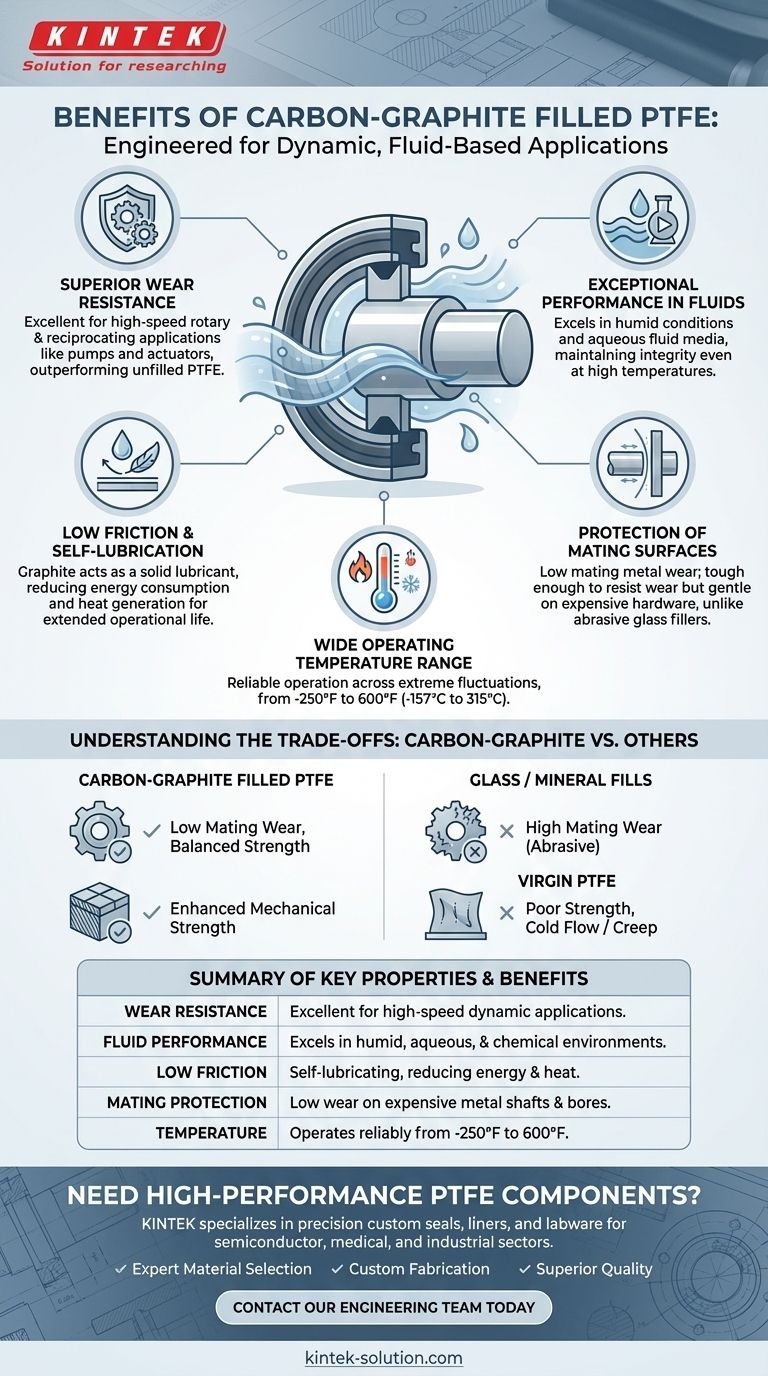

The Core Advantages of Carbon-Graphite Filler

To understand why this material is selected for critical components, we must break down the distinct advantages provided by the carbon and graphite blend.

Superior Wear Resistance in Dynamic Applications

The addition of carbon and graphite significantly improves the mechanical durability of PTFE. Carbon provides hardness and compressive strength, while graphite acts as a solid lubricant.

This synergy makes the material one of the best choices for high-speed rotary and reciprocating applications, such as in pumps and actuators, where unfilled PTFE would quickly fail.

Exceptional Performance in Fluids

This is the standout characteristic of carbon-graphite filled PTFE. It excels in humid conditions and aqueous fluid media, even at high temperatures.

Unlike some fillers that can be abrasive or degrade in certain fluids, this composite maintains its integrity and low-friction properties, making it a choice material for water pumps, chemical processing, and hydraulic systems.

Low Friction and Self-Lubrication

Graphite is a well-known dry lubricant. Its inclusion in the PTFE matrix creates a self-lubricating surface that reduces the coefficient of friction.

This results in smoother operation, lower energy consumption, and less heat generation in bearings and seals, extending the operational life of the entire assembly.

Protection of Mating Surfaces

A critical, and often overlooked, benefit is its low mating metal wear. The material is tough enough to resist wear on itself but not so abrasive that it damages the shafts or bores it runs against.

This is a significant advantage over harder fillers like glass or minerals, which can aggressively wear down expensive metal components over time.

Wide Operating Temperature Range

Carbon-graphite filled PTFE operates reliably across an exceptionally broad temperature range, typically cited between -250°F and 600°F (-157°C to 315°C).

This thermal stability allows it to be used in applications that experience extreme temperature fluctuations without significant degradation in performance.

Understanding the Trade-offs: Carbon-Graphite vs. Other Fillers

Choosing the right filler is about matching the material to the specific demands of the application. The strengths of carbon-graphite become clearest when compared to other common PTFE fillers.

Against Glass or Mineral Fills

Glass and mineral fillers often provide superior wear and extrusion resistance in high-pressure applications. However, this comes at a significant cost: high mating metal wear.

These fillers are abrasive and can score or erode metal shafts. Carbon-graphite is the preferred option when the integrity of the mating hardware is a primary concern.

Against Graphite-Only Fills

While graphite-only fill improves lubricity and wear resistance over virgin PTFE, the addition of carbon creates a mechanically superior composite.

The carbon component adds hardness and load-bearing capability, resulting in a higher overall wear resistance rating than a material filled only with graphite.

Against Virgin (Unfilled) PTFE

There is almost no scenario where virgin PTFE is preferable in a dynamic wear application. Unfilled PTFE suffers from poor wear resistance and "cold flow," or creep, where it deforms under sustained load.

The addition of a carbon-graphite filler is essential for providing the structural and mechanical integrity required for any demanding seal or bearing application.

Making the Right Choice for Your Application

Selecting the correct material is a matter of prioritizing your application's most critical needs.

- If your primary focus is... high-speed dynamic seals in wet or humid environments: Carbon-graphite filled PTFE is an ideal choice due to its excellent wear resistance and low friction in fluid media.

- If your primary focus is... protecting a critical or expensive mating surface: The low mating metal wear of carbon-graphite makes it a much safer option than abrasive glass or mineral fillers.

- If your primary focus is... maximum hardness and extrusion resistance at any cost: Consider a glass or mineral-filled PTFE, but be prepared for higher wear on your mating hardware.

Ultimately, selecting carbon-graphite filled PTFE is a strategic decision for applications where balanced performance and long-term system integrity are paramount.

Summary Table:

| Key Property | Benefit |

|---|---|

| Wear Resistance | Excellent for high-speed dynamic applications like seals and bearings. |

| Performance in Fluids | Excels in humid, aqueous, and chemical environments. |

| Low Friction | Self-lubricating, reducing energy consumption and heat. |

| Mating Surface Protection | Low wear on expensive metal shafts and bores. |

| Temperature Range | Operates reliably from -250°F to 600°F (-157°C to 315°C). |

Need high-performance PTFE components for your application?

KINTEK specializes in precision-manufactured PTFE components, including custom carbon-graphite filled seals, liners, and labware. Our expertise ensures you get the perfect material solution for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Material Selection: Ensure optimal performance and longevity for your specific fluid-based or dynamic application.

- Custom Fabrication: From prototypes to high-volume production, we tailor components to your exact specifications.

- Superior Quality: Precision production that protects your critical hardware and enhances system integrity.

Let's discuss your project requirements. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application