The primary benefits of 15% graphite-filled PTFE bushings are a significant improvement in wear resistance and thermal conductivity over standard PTFE. By adding graphite, the material gains durability and the ability to dissipate heat, drastically expanding its use in demanding applications while retaining its excellent self-lubricating properties.

The core challenge with virgin PTFE is its poor wear resistance under load. Adding 15% graphite is a strategic enhancement that solves this problem, creating a composite material ideal for high-speed, dry-running applications where longevity and heat management are critical.

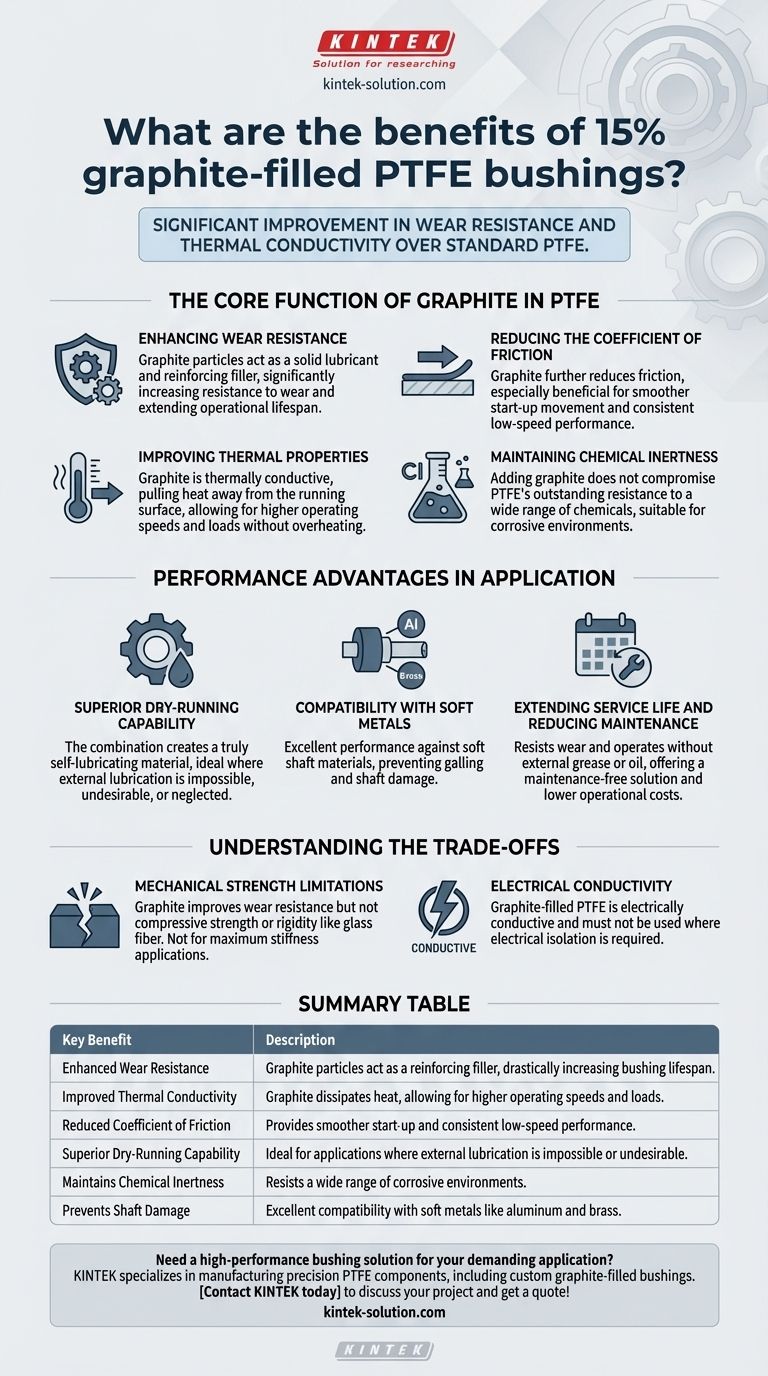

The Core Function of Graphite in PTFE

Adding graphite is not merely an enhancement; it fundamentally changes the performance characteristics of the base PTFE material, turning a soft, low-friction polymer into a robust engineering component.

Enhancing Wear Resistance

Virgin PTFE, while having an extremely low coefficient of friction, is mechanically soft and prone to "cold flow" or deformation under pressure.

The graphite particles act as a solid lubricant and a reinforcing filler, significantly increasing the bushing's resistance to wear and extending its operational lifespan.

Reducing the Coefficient of Friction

While PTFE is already one of the slickest materials known, graphite further reduces the coefficient of friction.

This is especially beneficial in reducing initial static friction, leading to smoother start-up movement and more consistent performance at low speeds.

Improving Thermal Properties

Friction generates heat. In virgin PTFE, this heat can become trapped at the contact surface, causing the material to expand and fail prematurely.

Graphite is thermally conductive. It effectively pulls heat away from the running surface and dissipates it through the bushing, allowing for higher operating speeds and loads without overheating.

Maintaining Chemical Inertness

A key advantage is that graphite is also highly inert. Adding it to PTFE does not compromise the material's outstanding resistance to a wide range of chemicals, making it suitable for corrosive environments.

Performance Advantages in Application

These material improvements translate directly into tangible benefits for mechanical systems, leading to more efficient and reliable operation.

Superior Dry-Running Capability

The combination of PTFE and graphite creates a truly self-lubricating material.

This makes these bushings ideal for applications where external lubrication is impossible, undesirable (e.g., food processing), or likely to be neglected.

Compatibility with Soft Metals

A standout feature is the material's excellent performance against softer shaft materials, such as aluminum or brass.

The graphite filler helps to prevent galling and shaft damage, which can be a risk with more abrasive fillers like glass fiber.

Extending Service Life and Reducing Maintenance

By resisting wear and operating without external grease or oil, these bushings offer a maintenance-free solution.

This directly results in lower operational costs, reduced downtime, and a longer overall service life for the application.

Understanding the Trade-offs

No material is perfect for every situation. Objectively assessing the limitations of graphite-filled PTFE is crucial for proper material selection.

Mechanical Strength Limitations

While graphite improves wear resistance, it does not add the same degree of compressive strength or rigidity as other fillers like glass fiber or carbon.

For extremely high static loads or applications requiring maximum stiffness, another type of filled PTFE may be a better choice.

Electrical Conductivity

Virgin PTFE is an excellent electrical insulator. The addition of graphite, a conductive material, fundamentally changes this property.

Graphite-filled PTFE is electrically conductive and must not be used in applications that require electrical isolation between the shaft and the housing.

Making the Right Choice for Your Goal

Selecting the correct bushing material depends entirely on the primary demands of your application. Use these guidelines to make an informed decision.

- If your primary focus is dry running at high speeds: 15% graphite-filled PTFE is an excellent choice due to its superior heat dissipation and low friction.

- If your primary focus is compatibility with soft metal shafts: The lubricating properties of graphite make this material ideal for preventing shaft damage.

- If your primary focus is maximum load capacity or rigidity: Consider a PTFE composite with a different filler, such as glass or carbon fiber, for greater mechanical strength.

- If your primary focus is electrical insulation: You must use virgin PTFE or a non-conductive filler, as the graphite content makes this bushing electrically conductive.

By understanding these key characteristics, you can confidently specify the right material to ensure optimal performance and longevity.

Summary Table:

| Key Benefit | Description |

|---|---|

| Enhanced Wear Resistance | Graphite particles act as a reinforcing filler, drastically increasing bushing lifespan. |

| Improved Thermal Conductivity | Graphite dissipates heat, allowing for higher operating speeds and loads. |

| Reduced Coefficient of Friction | Provides smoother start-up and consistent low-speed performance. |

| Superior Dry-Running Capability | Ideal for applications where external lubrication is impossible or undesirable. |

| Maintains Chemical Inertness | Resists a wide range of corrosive environments. |

| Prevents Shaft Damage | Excellent compatibility with soft metals like aluminum and brass. |

Need a high-performance bushing solution for your demanding application?

KINTEK specializes in manufacturing precision PTFE components, including custom graphite-filled bushings, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component that delivers superior wear resistance, thermal management, and maintenance-free operation.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments