At its core, the primary advantages of a PTFE coating for thrust washers are its exceptionally low coefficient of friction, high wear resistance, and superior resistance to chemicals and temperature. This combination creates a highly durable and versatile surface that ensures smooth, efficient operation in a wide variety of demanding environments.

The decision to use PTFE over other coatings isn't about finding a universally "best" material, but about prioritizing needs. PTFE is the definitive choice when the primary goals are minimizing friction and ensuring stability in chemically aggressive or high-temperature environments.

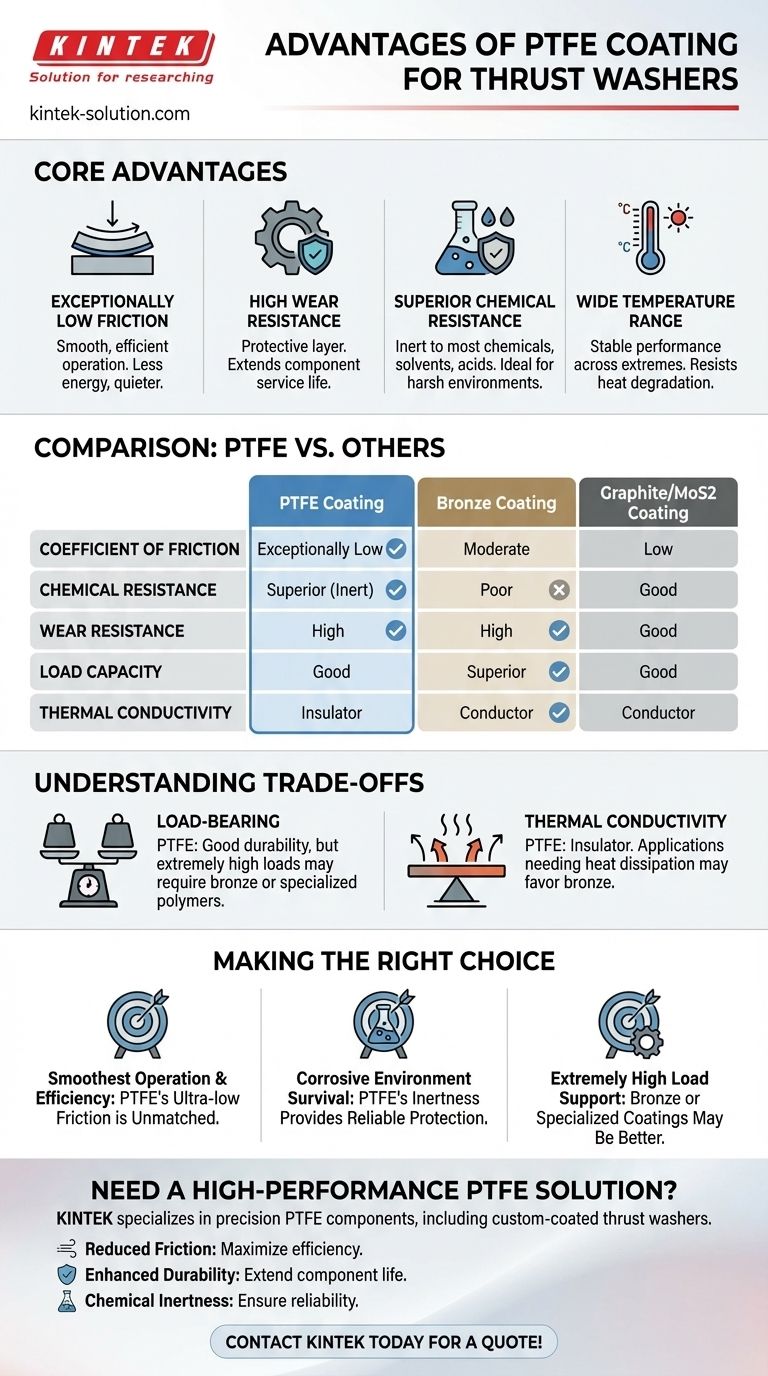

The Core Advantages of PTFE Coatings

Polytetrafluoroethylene (PTFE) is a synthetic polymer engineered for high-performance applications. When applied to a thrust washer, it imparts several key operational benefits.

Exceptionally Low Friction

PTFE is one of the most slippery materials known. This property, known as a low coefficient of friction, is its most significant advantage.

This allows moving parts, like a gear rotating against the washer, to glide with minimal resistance. The result is smoother, quieter, and more energy-efficient operation.

High Durability and Wear Resistance

The PTFE coating acts as a resilient, protective layer on the base metal of the thrust washer.

This sacrificial layer reduces direct metal-on-metal contact, significantly extending the service life of both the washer and the components it interfaces with.

Superior Chemical and Corrosion Resistance

PTFE is almost completely chemically inert. It is highly insoluble and does not react with the vast majority of chemicals, solvents, or acids.

This makes PTFE-coated washers ideal for applications exposed to harsh conditions, such as industrial chemical processing or saltwater fishing, where corrosion is a primary cause of failure.

Wide Operating Temperature Range

PTFE coatings remain stable and effective across a broad range of temperatures. They can withstand high heat without degrading, which is crucial in machinery where friction generates thermal stress.

How PTFE Compares to Other Common Coatings

While PTFE is a versatile choice, other materials are selected for specific properties. Understanding these differences clarifies where PTFE truly excels.

PTFE vs. Bronze

Bronze is often used in thrust washers for its high load-carrying capacity and good thermal conductivity.

However, it cannot match PTFE's extremely low friction or its comprehensive chemical resistance. In environments where smooth operation and corrosion protection are critical, PTFE is the superior choice.

PTFE vs. Graphite or Molybdenum Disulfide (MoS2)

Graphite and MoS2 are dry-film lubricants that also reduce friction. They can offer excellent lubrication and good load-bearing capabilities.

PTFE, however, generally provides a more consistent low-friction surface and is far more resistant to chemical attack, making it more reliable in corrosive or contaminated environments.

Understanding the Trade-offs

No material is perfect for every scenario. To make an informed decision, you must recognize the potential limitations of a PTFE coating.

Load-Bearing Capacity

While PTFE is durable, coatings like bronze or specialized polymers may offer superior performance under extremely high mechanical loads. For applications with immense pressure, the structural integrity of the base material becomes more critical.

Thermal Conductivity

PTFE is an insulator, not a conductor of heat. In applications where dissipating heat away from the contact point is a primary design requirement, a material like bronze might be a more suitable choice.

Application Process

The effectiveness of a PTFE coating is highly dependent on the quality of its application. Factors like coating thickness, surface preparation, and the curing process must be precisely controlled to achieve the desired performance.

Making the Right Choice for Your Goal

Your specific objective will determine the best coating for your thrust washer.

- If your primary focus is the smoothest possible operation and efficiency: PTFE's ultra-low coefficient of friction is unmatched.

- If your primary focus is surviving a corrosive or chemical environment: PTFE's inertness provides the most reliable protection.

- If your primary focus is supporting extremely high mechanical loads: A solid bronze washer or a coating engineered specifically for high pressure may be a better fit.

Ultimately, selecting the right coating empowers you to build a more reliable, efficient, and long-lasting mechanical system.

Summary Table:

| Advantage | PTFE Coating | Bronze Coating | Graphite/MoS2 Coating |

|---|---|---|---|

| Coefficient of Friction | Exceptionally Low | Moderate | Low |

| Chemical Resistance | Superior (Inert) | Poor | Good |

| Wear Resistance | High | High | Good |

| Load Capacity | Good | Superior | Good |

| Thermal Conductivity | Insulator | Conductor | Conductor |

Need a High-Performance PTFE Coating Solution?

KINTEK specializes in manufacturing precision PTFE components, including custom-coated thrust washers, seals, and liners. We help engineers in the semiconductor, medical, laboratory, and industrial sectors achieve superior performance with:

- Reduced Friction: Maximize efficiency and smooth operation.

- Enhanced Durability: Extend component life in harsh environments.

- Chemical Inertness: Ensure reliability with exposure to aggressive chemicals.

From prototypes to high-volume orders, our custom fabrication prioritizes precision to meet your exact specifications.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers