At their core, the advantages of hydrophobic Polytetrafluoroethylene (PTFE) membrane filters stem from a unique combination of extreme chemical resistance, inherent water repellency, and high thermal stability. These properties make PTFE the material of choice for filtering aggressive solvents, venting applications, and ensuring sample purity where other filter materials would degrade or contaminate the results.

The fundamental value of a hydrophobic PTFE filter is its reliability in harsh conditions. Its ability to resist virtually all chemicals while repelling water makes it an essential tool for protecting sensitive equipment and preserving the integrity of non-aqueous samples.

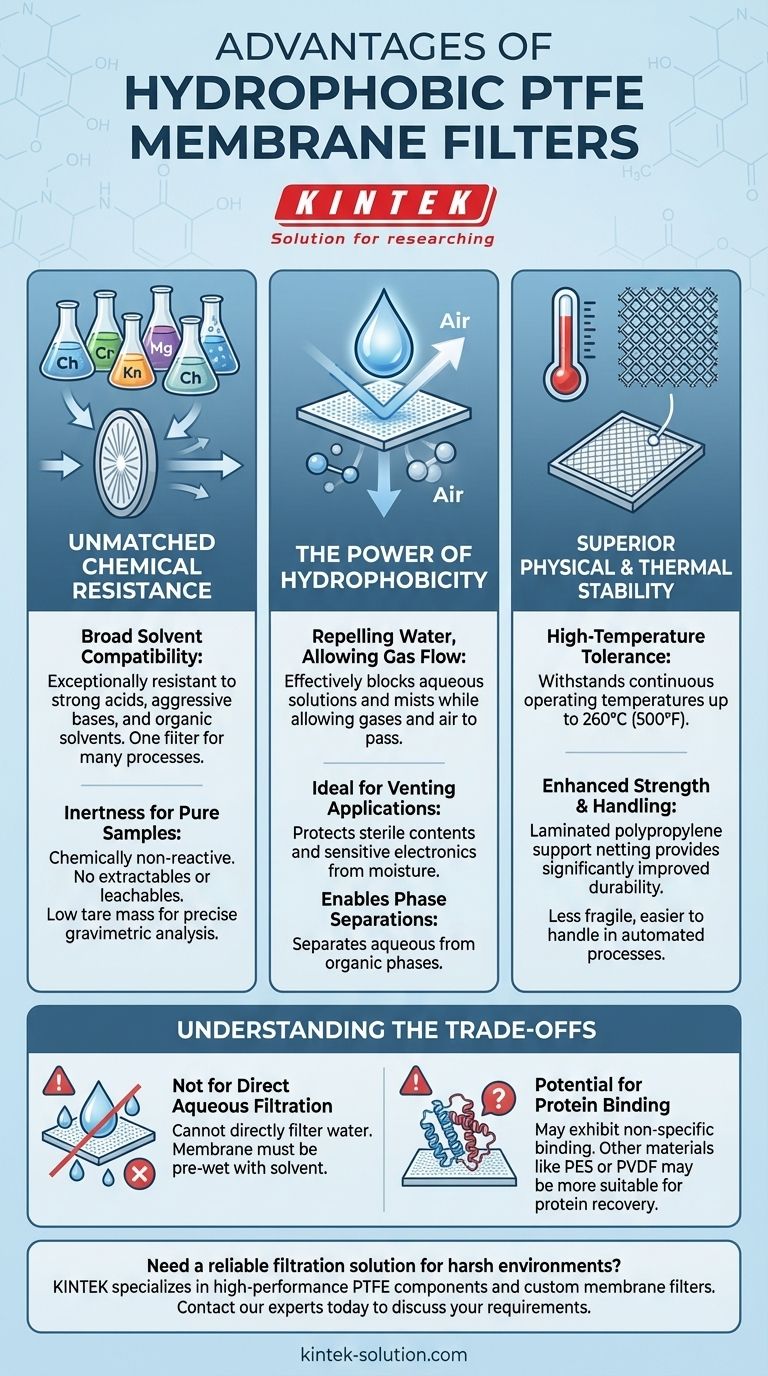

Unmatched Chemical Resistance

The most defining characteristic of PTFE is its chemical inertness. This property provides a level of security and sample purity that is difficult to achieve with other materials.

Broad Solvent Compatibility

PTFE membranes are exceptionally resistant to a wide range of chemicals, including strong acids, aggressive bases, and organic solvents.

This near-universal compatibility means you can use a single type of filter for many different processes, simplifying inventory and reducing the risk of filter failure due to chemical attack.

Inertness for Pure Samples

Because PTFE is chemically non-reactive, it will not interfere with your analytical determinations. The filter itself does not add extractables or leachables into the filtrate.

Furthermore, these filters have a low tare mass (a low starting weight), which is critical for gravimetric analysis where even minuscule changes in mass are significant.

The Power of Hydrophobicity

The term "hydrophobic" means the membrane actively repels water. This behavior is not just a minor feature; it is the foundation for several key applications.

Repelling Water, Allowing Gas Flow

A hydrophobic PTFE membrane effectively blocks aqueous solutions and mists while allowing gases and air to pass through freely.

This makes it the ideal material for venting applications, such as protecting sterile contents in a vessel or safeguarding sensitive electronics and vacuum pumps from moisture damage.

Enabling Phase Separations

This water-repellent property can be used to separate aqueous solutions from immiscible organic solvents. The PTFE membrane allows the organic solvent to pass while retaining the water-based phase.

Superior Physical and Thermal Stability

Beyond its chemical properties, PTFE is a physically robust material that performs reliably under demanding physical conditions.

High-Temperature Tolerance

PTFE membranes can withstand continuous operating temperatures up to 260°C (500°F). This makes them suitable for high-temperature air sampling and filtration processes where other polymer membranes would melt or degrade.

Enhanced Strength and Handling

Many PTFE membranes are laminated onto a polypropylene support netting. This backing provides significantly improved strength and handleability.

The lamination makes the filter less fragile and easier to handle without causing cracks or tears, which is especially important in automated processes or when handled with forceps.

Understanding the Trade-offs

While powerful, hydrophobic PTFE is not the universal solution for every filtration task. Understanding its limitations is key to using it correctly.

Not for Direct Aqueous Filtration

The most significant limitation is its hydrophobicity itself. You cannot directly filter water or aqueous solutions with a hydrophobic PTFE membrane, as the water will not pass through.

To filter aqueous solutions, the membrane must first be pre-wet with a low-surface-tension solvent like methanol or isopropanol, which adds an extra step to the workflow.

Potential for Protein Binding

PTFE can exhibit non-specific binding with certain proteins. For biological applications involving protein solutions, other materials like Polyethersulfone (PES) or Polyvinylidene Fluoride (PVDF) may be more suitable to maximize recovery.

Making the Right Choice for Your Application

To determine if a hydrophobic PTFE filter is right for you, consider your primary objective.

- If your primary focus is filtering aggressive solvents: PTFE's unmatched chemical resistance makes it the safest and most reliable choice.

- If your primary focus is venting or gas filtration: PTFE's hydrophobicity is essential for protecting your process from aqueous aerosols while allowing air to pass.

- If your primary focus is high-purity analytical sampling: PTFE's chemical inertness and low tare mass ensure your results are not compromised by the filter itself.

Ultimately, choosing a hydrophobic PTFE membrane is a decision for reliability and purity in chemically demanding environments.

Summary Table:

| Key Advantage | Core Benefit |

|---|---|

| Chemical Resistance | Resists strong acids, bases, and solvents; ensures sample purity. |

| Hydrophobicity | Repels water; ideal for venting and gas filtration. |

| Thermal Stability | Withstands temperatures up to 260°C (500°F). |

| Physical Strength | Laminated support provides durability for easy handling. |

Need a reliable filtration solution for harsh chemical environments?

KINTEK specializes in manufacturing high-performance PTFE components, including custom membrane filters, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a filter that guarantees purity and protects your critical processes.

Contact our experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability