The primary advantages of expanded PTFE (ePTFE) stem from its unique microporous structure, which imparts superior conformability, strength, and controlled porosity while retaining the exceptional chemical and thermal resistance of standard PTFE. This expansion process transforms solid PTFE into a soft, fibrous material, unlocking a new range of high-performance applications.

While standard PTFE is known for its rigidity and low-friction surface, ePTFE is engineered for flexibility and sealing. Its core advantage is the introduction of a soft, porous, and fibrous physical structure, making it uniquely capable of conforming to irregular surfaces and acting as a breathable barrier.

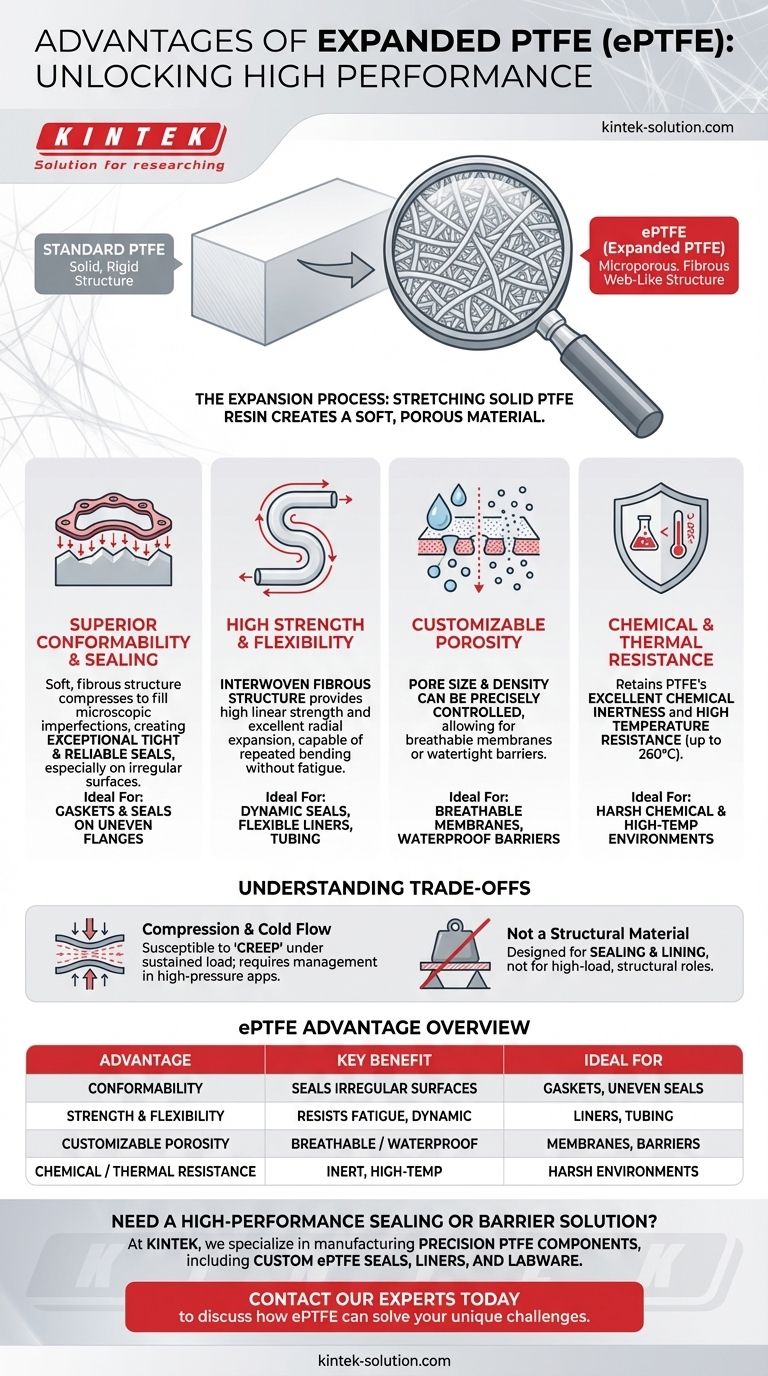

From Solid Block to Fibrous Web: What "Expanded" Means

To understand the benefits of ePTFE, we must first understand its physical transformation. The expansion process takes solid polytetrafluoroethylene resin and stretches it, creating a fundamentally different material at the microscopic level.

The Microporous Structure

The result of this expansion is a material composed of millions of interconnected microfibers, creating a web-like structure with countless tiny pores. This gives it a soft, flexible, and almost spongy texture, sometimes compared to a dense marshmallow.

Retaining PTFE's Core Strengths

Crucially, this new physical form does not sacrifice the inherent qualities of PTFE. ePTFE retains its parent material's remarkable properties, including high temperature resistance (up to 260°C), near-universal chemical inertness, UV resistance, and a low dielectric constant.

The Key Advantages of ePTFE's Structure

The fibrous, porous nature of ePTFE is not a flaw; it is the source of its most significant advantages over traditional PTFE and other materials.

Superior Conformability and Sealing

Standard, rigid PTFE is a poor choice for sealing uneven surfaces. In contrast, the soft and conformable nature of ePTFE allows it to compress and fill microscopic imperfections, creating an exceptionally tight and reliable seal, especially in gasket applications.

High Strength with Flexibility

The interwoven fibrous structure gives ePTFE a high linear strength and excellent radial expansion capability. It is both strong and highly flexible, able to withstand repeated bending and movement without fatigue or cracking, which would be impossible for solid PTFE.

Customizable Porosity

The size and density of the pores in ePTFE can be precisely controlled during manufacturing. This allows for tailored performance, creating materials that can be watertight at low pressure or engineered to be breathable membranes for medical or apparel applications.

Understanding the Trade-offs

No material is perfect for every application. Recognizing the limitations of ePTFE is essential for correct specification.

Compression and Cold Flow

Like all PTFE materials, ePTFE is susceptible to "creep" or "cold flow" under sustained load and temperature. Its softer structure means this must be carefully managed in high-pressure sealing applications to prevent the material from extruding from the joint.

Not a Structural Material

While strong for its weight, ePTFE is not designed for high-load, structural roles. It is a material for sealing, lining, and insulation, where its softness and flexibility are assets, not liabilities. Rigid forms of PTFE or filled-PTFE are better suited for components like bearings or rings.

Making the Right Choice for Your Goal

Selecting ePTFE is a decision to use a material that has been structurally engineered for specific tasks that standard polymers cannot handle.

- If your primary focus is creating a perfect seal on irregular or damaged surfaces: ePTFE's soft, conformable nature makes it the superior choice over rigid gaskets.

- If your primary focus is a breathable yet waterproof barrier: The customizable microporous structure of ePTFE is specifically designed for this function.

- If your primary focus is a flexible, chemically inert tubing or liner: ePTFE provides the durability and dynamic performance that solid PTFE lacks.

Ultimately, choosing ePTFE means leveraging an advanced material whose physical structure is precisely tailored for performance beyond the limits of its solid counterpart.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Superior Conformability | Soft, fibrous structure seals irregular surfaces | Gaskets, seals on uneven flanges |

| High Strength & Flexibility | Strong, flexible, resists fatigue | Dynamic seals, flexible liners, tubing |

| Customizable Porosity | Engineered microporous structure | Breathable membranes, waterproof barriers |

| Chemical & Thermal Resistance | Retains PTFE's inertness, handles temperatures up to 260°C | Harsh chemical and high-temperature environments |

Need a high-performance sealing or barrier solution?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom ePTFE seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution perfectly tailored to your application's demands in the semiconductor, medical, laboratory, or industrial sectors.

Contact our experts today to discuss how ePTFE can solve your unique challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs