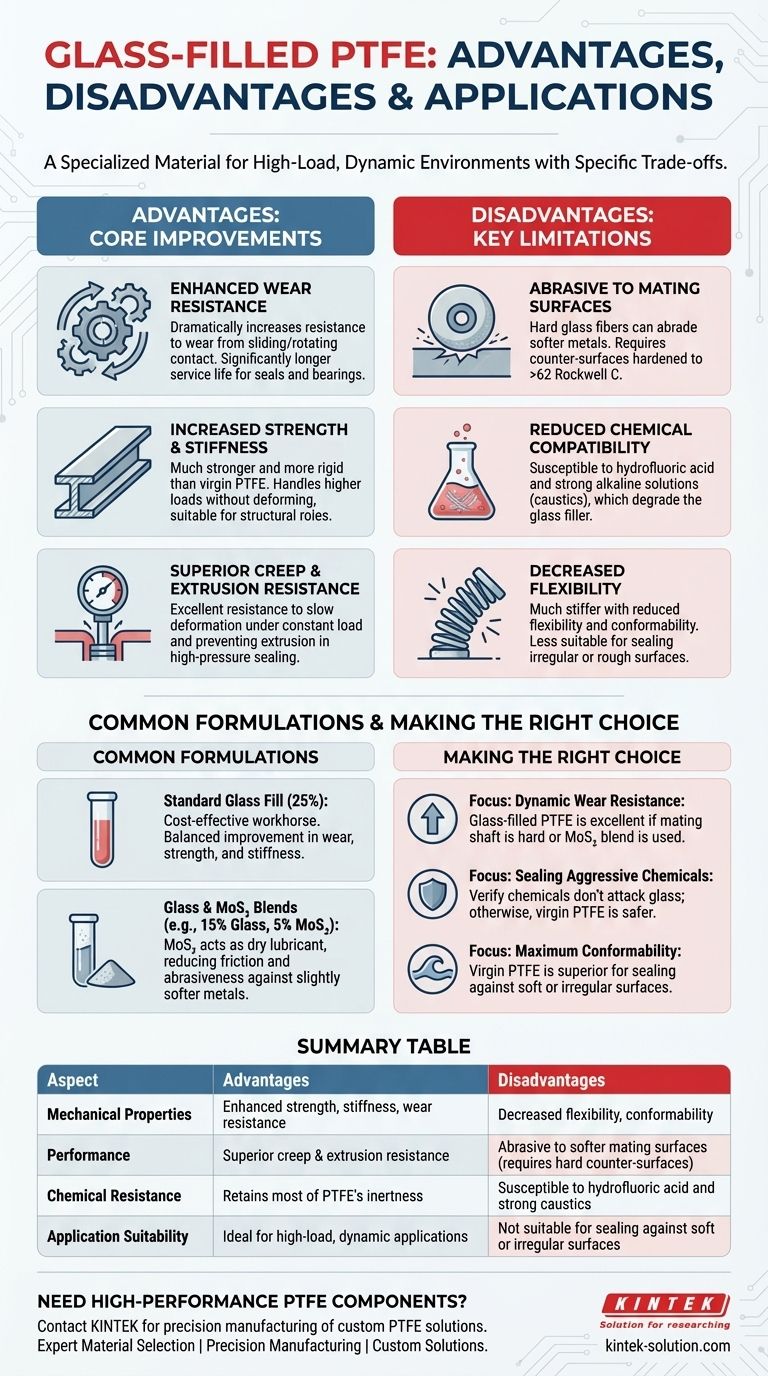

The primary advantage of glass-filled PTFE is its significantly enhanced mechanical strength and wear resistance over virgin PTFE, making it ideal for high-load, dynamic applications. Its key disadvantages are its abrasiveness, which can damage softer mating surfaces, and its susceptibility to specific chemicals that attack glass, such as hydrofluoric acid and strong caustics.

Choosing glass-filled PTFE involves a fundamental trade-off. You gain substantial improvements in strength, stiffness, and wear resistance, but you sacrifice the universal chemical compatibility and non-abrasive nature of virgin PTFE. This makes it a specialized material for demanding applications where its limitations are accounted for.

Why Add Glass to PTFE? The Core Improvements

Adding glass fibers, typically at a concentration of 25%, fundamentally changes the mechanical properties of PTFE. This transforms it from a soft, compliant material into a much more robust engineering plastic.

Enhanced Wear Resistance

Glass fibers distributed within the PTFE matrix dramatically increase its resistance to wear from sliding or rotating contact. This results in a significantly longer service life for components like seals and bearings.

Increased Strength and Stiffness

Compared to unfilled PTFE, the glass-filled variant is much stronger and more rigid. This allows it to handle higher loads without deforming, making it suitable for more demanding structural roles.

Superior Creep and Extrusion Resistance

Creep is a material's tendency to slowly deform under a constant load. Glass-filled PTFE has excellent creep resistance, maintaining its shape over time. This also improves extrusion resistance, preventing the material from being forced out of gaps in high-pressure sealing applications.

Understanding the Trade-offs: Key Limitations

While the mechanical benefits are clear, they come with critical limitations that must be respected in any design. Ignoring these trade-offs is a common cause of premature component failure.

Abrasiveness to Mating Surfaces

This is the most significant disadvantage. The hard glass fibers can abrade and damage softer metals. Glass-filled PTFE should only be used against very hard counter-surfaces, typically those hardened to greater than 62 Rockwell C.

Reduced Chemical Compatibility

While PTFE is famous for being nearly universally inert, the glass filler is not. Glass is attacked by hydrofluoric acid and strong alkaline solutions (caustics). Using glass-filled PTFE in these environments will cause the filler to degrade, leading to material failure.

Decreased Flexibility

The addition of glass fibers makes the material much stiffer, which reduces its flexibility and conformability compared to virgin PTFE. It is less suitable for applications requiring a seal to conform to irregular or rough surfaces.

Common Formulations and Their Purpose

Not all glass-filled PTFE is the same. The specific blend is chosen to optimize performance for a given application.

Standard Glass Fill (25%)

This is the most common formulation, providing a balanced improvement in wear resistance, strength, and stiffness. It serves as a cost-effective workhorse for many industrial uses.

Glass and MoS₂ Blends

To counteract the high abrasiveness of glass, some formulations include molybdenum disulfide (MoS₂) as a secondary filler. A common blend is 15% glass and 5% MoS₂. The MoS₂ acts as a dry lubricant, reducing friction and making the material safer for use against slightly softer metal surfaces.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is dynamic wear resistance: Glass-filled PTFE is an excellent choice, provided the mating shaft is sufficiently hard or you use a MoS₂ blend.

- If your primary focus is sealing aggressive chemicals: You must verify that the chemicals are not among those that attack glass; otherwise, virgin PTFE is the safer option.

- If your primary focus is maximum conformability or sealing against a soft surface: Virgin PTFE is the superior material for these applications.

Ultimately, selecting glass-filled PTFE is a deliberate engineering choice to gain mechanical performance where its specific limitations are understood and accounted for.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Mechanical Properties | Enhanced strength, stiffness, and wear resistance | Decreased flexibility and conformability |

| Performance | Superior creep and extrusion resistance | Abrasive to softer mating surfaces (requires hard counter-surfaces) |

| Chemical Resistance | Retains most of PTFE's inertness | Susceptible to hydrofluoric acid and strong caustics |

| Application Suitability | Ideal for high-load, dynamic applications | Not suitable for sealing against soft or irregular surfaces |

Need High-Performance PTFE Components for Demanding Applications?

At KINTEK, we specialize in precision manufacturing of custom PTFE components, including glass-filled formulations, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get the right material solution that balances performance with durability.

Let us help you optimize your application:

- Expert Material Selection: We'll guide you to the ideal PTFE formulation for your specific needs.

- Precision Manufacturing: From seals and liners to complex labware, we deliver components made to exact specifications.

- Custom Solutions: We offer custom fabrication to meet unique application challenges.

Contact KINTEK today to discuss your project and discover how our specialized PTFE components can enhance your equipment's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications