In industrial machinery, Teflon (PTFE) lip seals are specifically used in high-performance rotating equipment like pumps, compressors, and gearboxes. They are chosen for demanding environments where standard elastomer seals would quickly fail, particularly in the chemical processing, pharmaceutical, aerospace, and food and beverage industries.

The core reason for using Teflon lip seals is not versatility, but specialization. They are the engineered solution for extreme operating conditions—high speeds, high pressures, aggressive chemicals, or wide temperature ranges—that exceed the physical limits of traditional rubber seals.

The Unique Properties Driving Adoption

The decision to use a Teflon lip seal is driven by a need for performance under stress. Their material composition offers a unique combination of advantages that justify their use in critical applications.

Superior Chemical Resistance

Teflon's inert nature makes it resistant to nearly all industrial chemicals and solvents. This is critical in chemical processing pumps and pharmaceutical equipment where the seal must maintain its integrity when exposed to corrosive or reactive fluids.

High-Temperature Stability

These seals operate reliably across an exceptionally wide temperature range, typically from -40°C to 220°C. This makes them essential for high-heat environments like automotive engines and aerospace systems, as well as cryogenic applications where other materials become brittle.

Low Friction and High Speeds

PTFE has an extremely low coefficient of friction. This property allows for sealing on shafts rotating at very high speeds—often up to 40 m/s—without generating excessive heat, which would otherwise lead to premature wear and seal failure in gearboxes and compressors.

High-Pressure Capability

Engineered Teflon lip seals are designed to withstand significant pressures, in some cases up to 250 Bar (3600 PSI). This makes them indispensable in hydraulic systems and high-pressure compressors where standard seals would be extruded or destroyed.

Excellent Wear Resistance

The durable, self-lubricating properties of Teflon significantly reduce wear on both the seal and the rotating shaft. This leads to longer service intervals and minimal maintenance, which is a major advantage in continuously operating machinery like industrial pumps and conveyor systems.

Where These Properties Matter Most: Core Applications

The theoretical advantages of Teflon seals translate directly into their use in specific, high-stakes industrial machinery.

Pumps and Compressors

In this equipment, seals are constantly exposed to process fluids, high pressures, and continuous rotation. Teflon seals are used to handle corrosive chemicals, prevent leaks under high compression, and ensure long-term reliability without frequent replacement.

Industrial Gearboxes

High rotational speeds in gearboxes generate significant heat and stress. Teflon lip seals' low-friction and high-temperature properties prevent overheating and wear, maintaining the integrity of the lubricant and protecting the internal components.

Aerospace and Automotive Engines

These applications involve extreme temperature fluctuations, from cold starts to high operating heat, alongside high-speed rotating shafts. Teflon seals maintain their flexibility and sealing capability across this entire range, ensuring critical systems like engines and actuators function safely.

Pharmaceutical and Food & Beverage Equipment

Sterility and purity are paramount in these industries. Teflon's chemical inertness prevents it from contaminating the product. Furthermore, its ability to withstand high-temperature sterilization processes makes it an ideal choice for mixers, pumps, and filling machines.

Understanding the Trade-offs

While powerful, Teflon lip seals are not a universal solution. Their specialized nature comes with specific considerations.

Less Forgiving Installation

Compared to flexible rubber seals, PTFE is a more rigid material. This requires greater care and precision during installation to avoid damaging the sealing lip, which could compromise its performance.

Higher Initial Cost

The advanced materials and manufacturing processes required for high-performance Teflon seals result in a higher upfront cost than standard elastomer seals. This cost is justified by their longer lifespan and reliability in extreme conditions.

Not a Universal Replacement

Using a Teflon seal in a simple, low-stress application is often unnecessary and not cost-effective. They are specifically engineered for problems that commodity seals cannot solve.

Making the Right Choice for Your Application

The key is to match the seal's capabilities to the specific demands of your machinery.

- If your primary focus is handling aggressive chemicals or extreme temperatures: Teflon seals are the default choice due to their unmatched material stability.

- If your primary focus is managing high shaft speeds or high pressures: The low-friction and robust design of a Teflon seal are essential for preventing failure and ensuring longevity.

- If your primary focus is a general-purpose, low-stress application: A standard elastomer (rubber) seal is often the more practical and cost-effective solution.

Ultimately, choosing the correct seal is about matching the material's engineering to the precise demands of its operating environment.

Summary Table:

| Key Property | Key Application | Performance Benefit |

|---|---|---|

| Superior Chemical Resistance | Chemical Processing Pumps | Seals against corrosive fluids without degradation |

| High-Temperature Stability (-40°C to 220°C) | Aerospace & Automotive Engines | Maintains performance from cold starts to extreme heat |

| Low Friction & High Speeds (up to 40 m/s) | Industrial Gearboxes | Prevents overheating and wear at high RPMs |

| High-Pressure Capability (up to 250 Bar) | Hydraulic Systems & Compressors | Prevents extrusion and failure under extreme pressure |

| Excellent Wear Resistance | Continuously Operating Pumps | Enables longer service life and reduced maintenance |

Need a High-Performance Sealing Solution?

When your industrial machinery operates under extreme conditions—be it high speeds, aggressive chemicals, wide temperature swings, or intense pressure—standard seals simply aren't enough. That's where KINTEK's specialized PTFE components make the difference.

We help manufacturers in the semiconductor, medical, laboratory, and industrial sectors solve their most demanding sealing challenges.

Why Partner with KINTEK?

- Precision Production: We manufacture PTFE seals, liners, and labware to exacting specifications for reliable performance.

- Custom Fabrication: From initial prototypes to high-volume production runs, we tailor the solution to your specific application.

- Expertise in Extreme Conditions: We understand the engineering required for seals that must perform in the most challenging environments.

Let's engineer a solution for your critical application. Contact our experts today for a consultation.

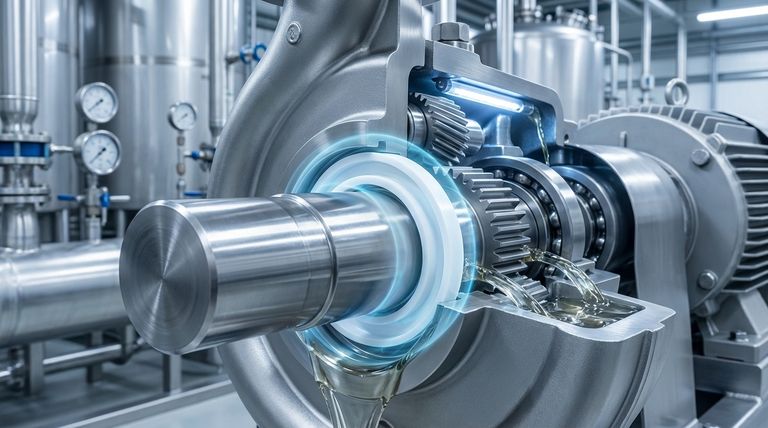

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability