In short, PTFE lip seals are used in critical industrial equipment where conventional elastomer seals fail due to extreme conditions. Common applications include centrifugal compressors, high-speed gearboxes, pumps, wind turbines, and oil & gas equipment like API 6A wellheads, as well as specialized machinery in chemical processing, food, and pharmaceutical manufacturing.

The core reason for their widespread use is straightforward: PTFE seals provide unparalleled reliability in environments with high speeds, aggressive chemicals, or extreme temperatures—from cryogenic to high heat—that would quickly destroy standard rubber seals.

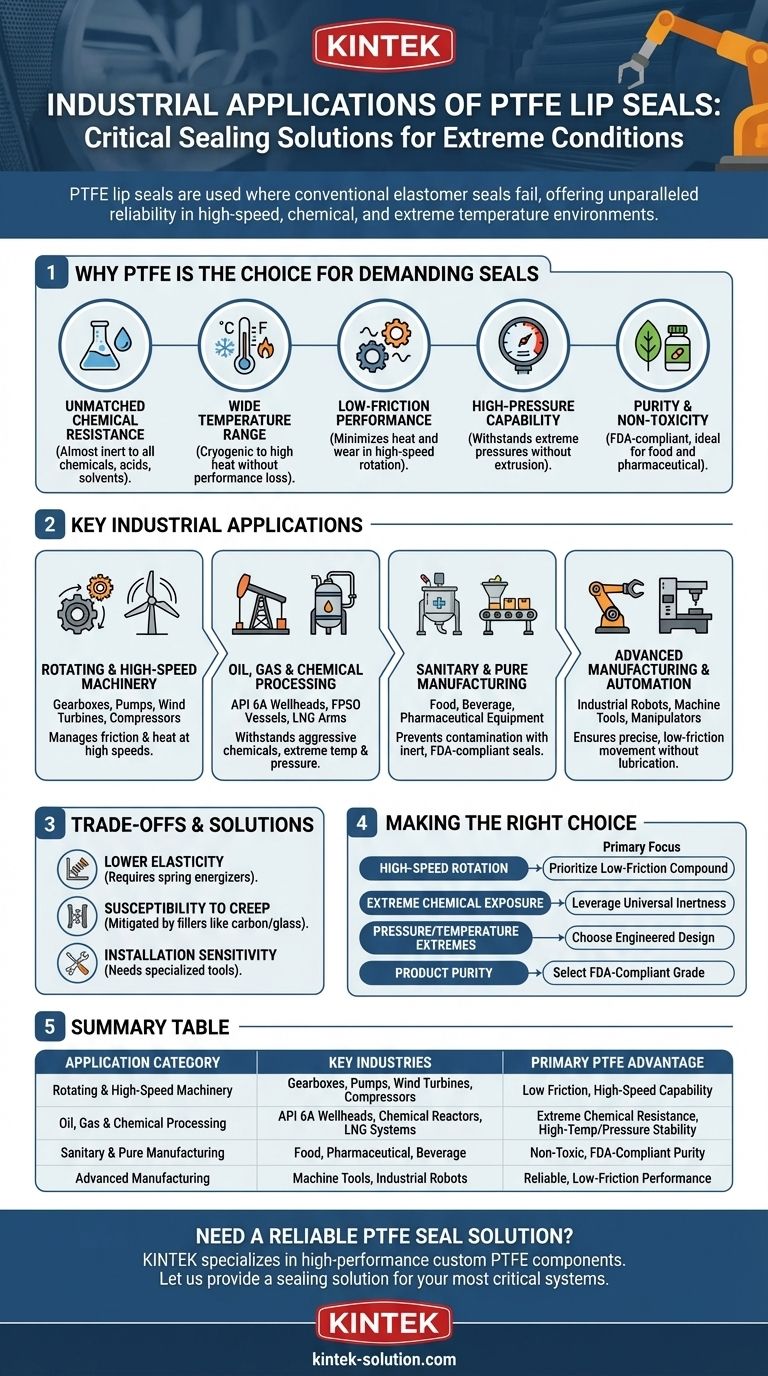

Why PTFE is the Material of Choice for Demanding Seals

The decision to use a PTFE lip seal is driven by the operational environment. Standard elastomeric (rubber) seals have limitations in temperature, chemical compatibility, and rotational speed. PTFE, or Polytetrafluoroethylene, overcomes these limitations through a unique combination of material properties.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it the default choice for seals in chemical processing plants, pharmaceutical mixers, and oil and gas equipment where exposure to corrosive media is constant.

Wide Operating Temperature Range

PTFE seals maintain their integrity and performance across an exceptionally broad temperature spectrum. They are used in cryogenic applications like LNG loading arms and nozzles, as well as in high-temperature equipment like compressors and gearboxes where heat buildup is significant.

Low-Friction Performance

Known for its extremely low coefficient of friction (similar to wet ice on wet ice), PTFE is ideal for high-speed rotating shafts. This property minimizes frictional heat generation, reduces energy consumption, and prevents the "stick-slip" phenomenon that can cause vibration and wear in dynamic systems.

High-Pressure Capability

Specially designed PTFE lip seals can handle extreme pressures found in applications like API 6A wellhead equipment and high-pressure compressors. The material's strength prevents extrusion and ensures a reliable seal where elastomers would fail.

Purity and Non-Toxicity

Many grades of PTFE are compliant with FDA and other regulations for food and pharmaceutical contact. Its inert nature means it will not contaminate the processed media, making it essential for agitators, pumps, and valves in these sanitary industries.

A Closer Look at Key Industrial Applications

Understanding the "why" behind material selection helps clarify where these seals are most effective. We can group the primary applications by the core problem they solve.

Rotating and High-Speed Machinery

In equipment like gearboxes, centrifugal compressors, pumps, and wind turbines, the primary challenge is managing friction and heat on a rapidly rotating shaft. PTFE's low-friction nature allows for higher surface speeds without overheating or premature wear, ensuring longer service life and greater reliability.

Oil, Gas, and Chemical Processing

For API 6A wellheads, FPSO vessels, LNG arms, and chemical agitators, the seal must withstand aggressive chemicals and extreme temperatures or pressures. PTFE's chemical inertness and thermal stability make it one of the only viable materials for ensuring safe and leak-free operation in these hazardous environments.

Advanced Manufacturing and Automation

Equipment like machine tools, industrial robots, and manipulators requires precise, reliable movement without contamination from lubricants. PTFE seals provide smooth, low-friction operation that contributes to the accuracy and longevity of these automated systems.

Understanding the Trade-offs of PTFE Seals

While highly effective, PTFE seals are not a universal solution. Understanding their limitations is key to proper application and design.

Lower Elasticity

Unlike rubber, PTFE is a relatively rigid plastic with poor elastic memory. This means it doesn't "spring back" into shape as effectively. To compensate, most PTFE lip seals incorporate a metallic spring or energizer to maintain constant sealing force against the shaft.

Susceptibility to Creep

Under sustained pressure and elevated temperatures, PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time. Seal designs mitigate this by using fillers (like carbon, glass, or bronze) in the PTFE compound to improve dimensional stability and creep resistance.

Installation Sensitivity

Due to its rigidity, installing a PTFE seal requires more care than a flexible elastomeric seal. Specialized tools are often needed to avoid scratching or deforming the seal lip, which could compromise its performance.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the demands of your operating environment.

- If your primary focus is high-speed rotation: Prioritize a low-friction PTFE compound to minimize heat generation and wear in equipment like gearboxes and pumps.

- If your primary focus is extreme chemical exposure: Leverage PTFE's near-universal inertness for applications in chemical reactors, mixers, and processing lines.

- If your primary focus is pressure or temperature extremes: Choose a seal design engineered specifically for the pressure and temperature range, such as those used in compressors or LNG systems.

- If your primary focus is product purity: Ensure you select an FDA-compliant or certified grade of PTFE for food, beverage, and pharmaceutical applications.

Ultimately, choosing a PTFE lip seal is an investment in reliability for your most critical and demanding industrial systems.

Summary Table:

| Application Category | Key Industries | Primary PTFE Advantage |

|---|---|---|

| Rotating & High-Speed Machinery | Gearboxes, Pumps, Wind Turbines, Compressors | Low Friction, High-Speed Capability |

| Oil, Gas & Chemical Processing | API 6A Wellheads, Chemical Reactors, LNG Systems | Extreme Chemical Resistance, High-Temp/Pressure Stability |

| Sanitary & Pure Manufacturing | Food, Pharmaceutical, Beverage | Non-Toxic, FDA-Compliant Purity |

| Advanced Manufacturing | Machine Tools, Industrial Robots | Reliable, Low-Friction Performance |

Need a Reliable PTFE Seal Solution for Your Demanding Application?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Let us provide a sealing solution that ensures reliability in your most critical systems.

Contact us today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability