In short, the most common Expanded PTFE products are sheets, joint sealants, and tapes. These forms are overwhelmingly used to create high-performance gaskets and seals for demanding industrial applications. Unlike standard, solid PTFE, Expanded PTFE (ePTFE) is a soft, microporous material composed of tiny fibers, which gives it unique sealing capabilities.

The core takeaway is that Expanded PTFE is not a general-purpose plastic but a specialized sealing material. Its value comes from combining the extreme chemical and thermal resistance of PTFE with a unique fibrous structure that allows it to compress and conform to imperfect surfaces, creating an exceptionally tight seal.

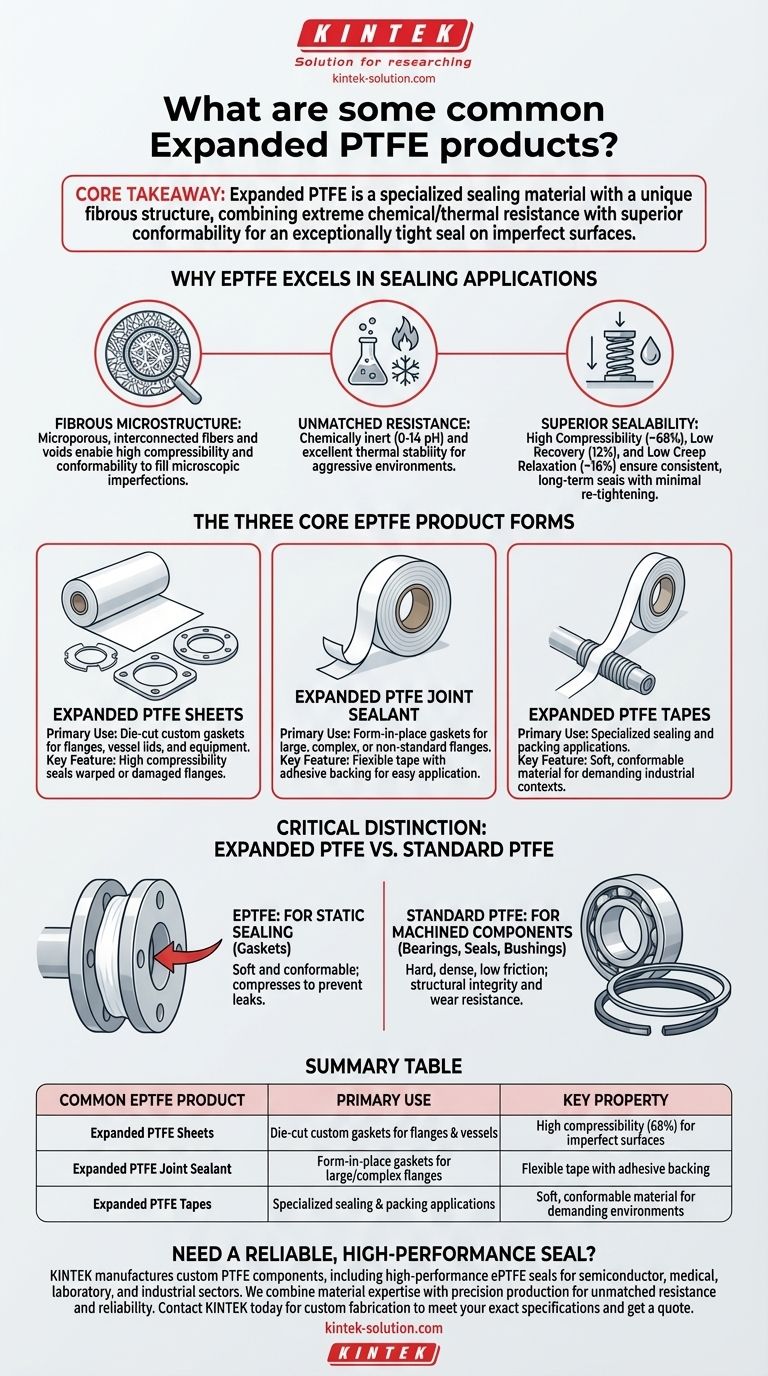

Why ePTFE Excels in Sealing Applications

The utility of ePTFE products stems directly from the material's unique physical structure, which is created during the expansion process. This process transforms solid PTFE into a web of fibers and voids.

The Source of Its Properties: A Fibrous Microstructure

ePTFE is not a solid block of plastic. It is a microporous material made of nodes interconnected by very fine fibers.

This structure is what makes it soft and highly compressible, allowing it to fill in the microscopic imperfections found on virtually all industrial sealing surfaces.

Unmatched Chemical and Thermal Resistance

Like all PTFE materials, ePTFE is nearly chemically inert across the entire 0-14 pH range. It withstands attack from the most aggressive chemicals.

It also boasts excellent thermal resistance, making it suitable for a wide range of operating temperatures.

Superior Conformability and Sealability

ePTFE is known for its high compressibility (around 68%) and relatively low recovery (12%). This means it crushes down easily under pressure to create a seal and does not spring back significantly.

This property, combined with low creep relaxation (16% at 73°F), ensures the material maintains a strong, consistent seal over time without needing constant re-tightening of bolts. The result is exceptional sealability, with leakage rates as low as 0.0 ml/hr for some fluids.

The Three Core ePTFE Product Forms

While the base material is the same, ePTFE is commercialized in a few key formats to solve different sealing challenges.

Expanded PTFE Sheets

This is arguably the most common form. Large sheets of ePTFE are used to die-cut custom gaskets for flanges, vessel lids, and other equipment.

Its softness allows it to seal warped or damaged flanges that would cause leaks with harder, more traditional gasket materials.

Expanded PTFE Joint Sealant

This product is essentially ePTFE in the form of a thin, flexible tape with an adhesive backing strip.

It is often called a "form-in-place" gasket. You apply the tape directly to the flange surface, overlap the ends, and bolt the connection together. This is ideal for very large, complex, or non-standard flanges where cutting a single-piece gasket would be impossible or wasteful.

Expanded PTFE Tapes

Beyond joint sealant, ePTFE is also formed into various tapes for specialized sealing and packing applications. While different from standard thread-seal tape, it serves a similar purpose in more demanding industrial contexts.

Critical Distinction: Expanded PTFE vs. Standard PTFE

It is vital not to confuse the products made from soft, fibrous ePTFE with those made from hard, solid PTFE. The references list many parts that are exclusively made from standard PTFE.

ePTFE is for Static Sealing

The softness and conformability of ePTFE make it the perfect choice for static sealing applications—primarily gaskets. Its job is to be compressed between two stationary surfaces to prevent leaks.

Standard PTFE is for Machined Components

Standard, non-expanded PTFE is a hard, dense plastic prized for its low friction and wear resistance.

It is machined into dynamic components like bearings, piston rings, V-rings, seals, and bushings. These parts require structural integrity and a slick surface, not the compressibility of ePTFE.

Making the Right Choice for Your Goal

Understanding the fundamental difference between these two forms of PTFE is key to selecting the correct material.

- If your primary focus is sealing aggressive chemicals or extreme temperatures on irregular surfaces: Expanded PTFE sheets or joint sealants are the definitive choice.

- If your primary focus is creating a custom, form-in-place gasket for large or non-standard equipment: Expanded PTFE joint sealant tape offers the most practical and reliable solution.

- If you need a hard, low-friction, or structural component like a bearing, bushing, or insulator: You must use standard (non-expanded) PTFE, as ePTFE lacks the necessary rigidity.

Ultimately, choosing the right material begins with understanding that for PTFE, its physical form dictates its industrial function.

Summary Table:

| Common ePTFE Product | Primary Use | Key Property |

|---|---|---|

| Expanded PTFE Sheets | Die-cut custom gaskets for flanges and vessels | High compressibility (68%) for sealing imperfect surfaces |

| Expanded PTFE Joint Sealant | Form-in-place gaskets for large or complex flanges | Flexible tape with adhesive backing for easy application |

| Expanded PTFE Tapes | Specialized sealing and packing applications | Soft, conformable material for demanding environments |

Need a Reliable, High-Performance Seal?

Understanding the difference between ePTFE and standard PTFE is the first step. The next is partnering with a manufacturer who can deliver the precision and quality your application demands.

KINTEK manufactures custom PTFE components, including high-performance ePTFE seals, for the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with precision production to ensure your seals provide unmatched chemical resistance, thermal stability, and long-term reliability.

Whether you need a prototype or a high-volume order, we provide custom fabrication to meet your exact specifications.

Contact KINTEK today to discuss your sealing challenge and get a quote for your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability