Based on its unique electrical properties, PTFE is most commonly used for high-frequency coaxial cables, printed circuit boards (PCBs) for radio frequency applications, high-voltage insulators and connectors, and protective radomes for antennae. Its value comes from a combination of excellent insulation capabilities and minimal interference with high-frequency signals, making it a critical material in demanding aerospace, communications, and computing assemblies.

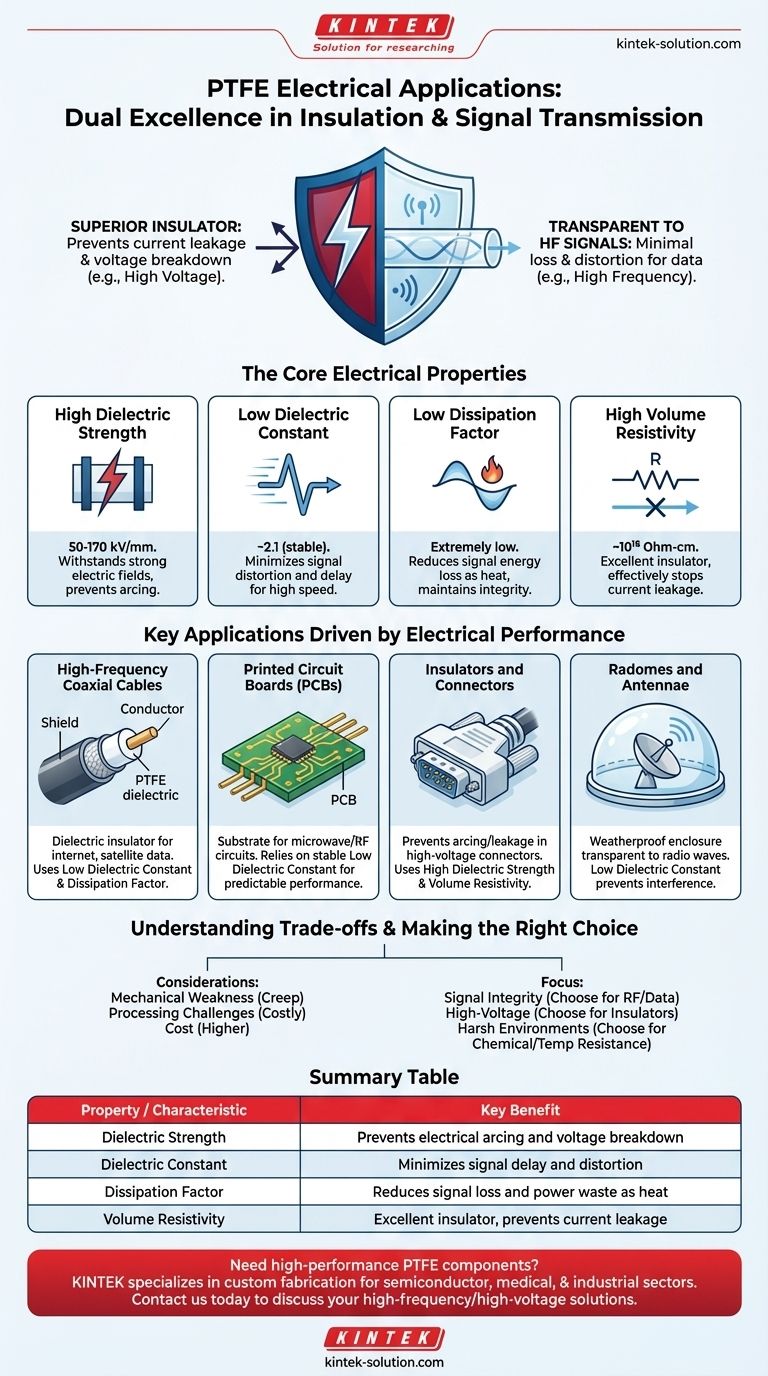

The core reason PTFE is chosen for electrical applications is its dual excellence: it is a superior insulator that prevents current leakage and voltage breakdown, while also being nearly transparent to high-frequency signals, ensuring data and transmissions pass through with minimal loss or distortion.

The Core Electrical Properties of PTFE

To understand why PTFE is so widely used, it's essential to understand the specific electrical characteristics that set it apart. These properties work in concert to deliver high performance where other materials fail.

High Dielectric Strength

Dielectric strength measures a material's ability to act as an insulator under high voltage.

PTFE has a very high dielectric strength, typically between 50-170 kV/mm. This means it can withstand a very strong electric field before it breaks down and allows current to pass, preventing arcing or short circuits.

Low Dielectric Constant

The dielectric constant indicates how much electrical energy a material can store in an electric field.

PTFE's dielectric constant is exceptionally low and stable (around 2.1) across a wide range of frequencies. This is critical because it minimizes signal distortion and delay, allowing for clean, fast transmission of data in high-speed applications.

Low Dissipation Factor

The dissipation factor (or loss tangent) quantifies how much signal energy is lost as heat when it passes through the material.

PTFE has an extremely low dissipation factor. This ensures that very little signal power is wasted, which is vital for maintaining signal integrity and efficiency in high-frequency cables and circuits.

High Volume Resistivity

Resistivity measures how strongly a material opposes the flow of electric current through its bulk.

With a volume resistivity around 10¹⁸ Ohm-cm, PTFE is one of the best electrical insulators available. It effectively stops current leakage, ensuring electricity flows only where it is intended.

Key Applications Driven by Electrical Performance

These four properties make PTFE the material of choice for several critical electronic and communication components.

High-Frequency Coaxial Cables

In high-frequency cables, such as those used for internet, satellite, and communications data, PTFE is used as the dielectric insulator separating the central conductor from the outer shield.

Its low dielectric constant and low dissipation factor are essential here. They ensure that high-frequency signals travel through the cable with minimal loss and distortion, preserving the integrity of the data being transmitted.

Printed Circuit Boards (PCBs)

For circuits operating at microwave or radio frequencies (RF), standard board materials like FR-4 are inadequate.

PTFE is used as the substrate for these specialized PCBs. Its stable low dielectric constant ensures predictable circuit performance, which is crucial for devices like radar systems, amplifiers, and high-speed communication hardware.

Insulators and Connectors

In connectors, sockets, and terminals that handle high voltages, insulation is paramount.

PTFE's high dielectric strength and high volume resistivity prevent electrical arcing and leakage between conductive pins. This guarantees both safety and reliable operation in everything from aerospace wiring to scientific equipment.

Radomes and Antennae

A radome is a structural, weatherproof enclosure that protects a microwave antenna.

The material must be transparent to radio waves. PTFE's very low dielectric constant allows radar and communication signals to pass through with almost no absorption or distortion, protecting sensitive equipment without interfering with its function.

Understanding the Trade-offs

While its electrical properties are exceptional, PTFE is not the solution for every problem. A complete technical assessment requires acknowledging its limitations.

Mechanical Weakness

PTFE is a relatively soft material and is subject to "creep" or "cold flow," meaning it can slowly deform over time when under a constant mechanical load. This makes it unsuitable for high-load structural components without reinforcement.

Processing Challenges

Unlike many thermoplastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques. It must be processed using more complex and costly methods like compression molding and sintering.

Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than common commodity plastics. Its use is typically justified only when its unique combination of electrical, chemical, and thermal properties is a strict requirement.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary performance driver of your application.

- If your primary focus is high-frequency signal integrity: PTFE is the ideal choice for applications like RF circuits and high-speed data cables due to its low dielectric constant and low dissipation factor.

- If your primary focus is high-voltage insulation: PTFE's high dielectric strength and volume resistivity make it a top-tier material for insulators, connectors, and wire jacketing in demanding environments.

- If you need electrical performance in a harsh environment: Choose PTFE when you require excellent electrical properties combined with resistance to extreme temperatures or corrosive chemicals.

Ultimately, PTFE's electrical characteristics enable the function and reliability of much of today's most advanced electronic and communication technology.

Summary Table:

| Property | Value / Characteristic | Key Benefit |

|---|---|---|

| Dielectric Strength | 50-170 kV/mm | Prevents electrical arcing and voltage breakdown |

| Dielectric Constant | ~2.1 (stable across frequencies) | Minimizes signal delay and distortion |

| Dissipation Factor | Extremely low | Reduces signal loss and power waste as heat |

| Volume Resistivity | ~10¹⁸ Ohm-cm | Excellent insulator, prevents current leakage |

Need high-performance PTFE components for your critical electrical applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your high-frequency and high-voltage assemblies meet the highest standards of reliability and performance.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific electrical and environmental requirements.

Contact us today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support