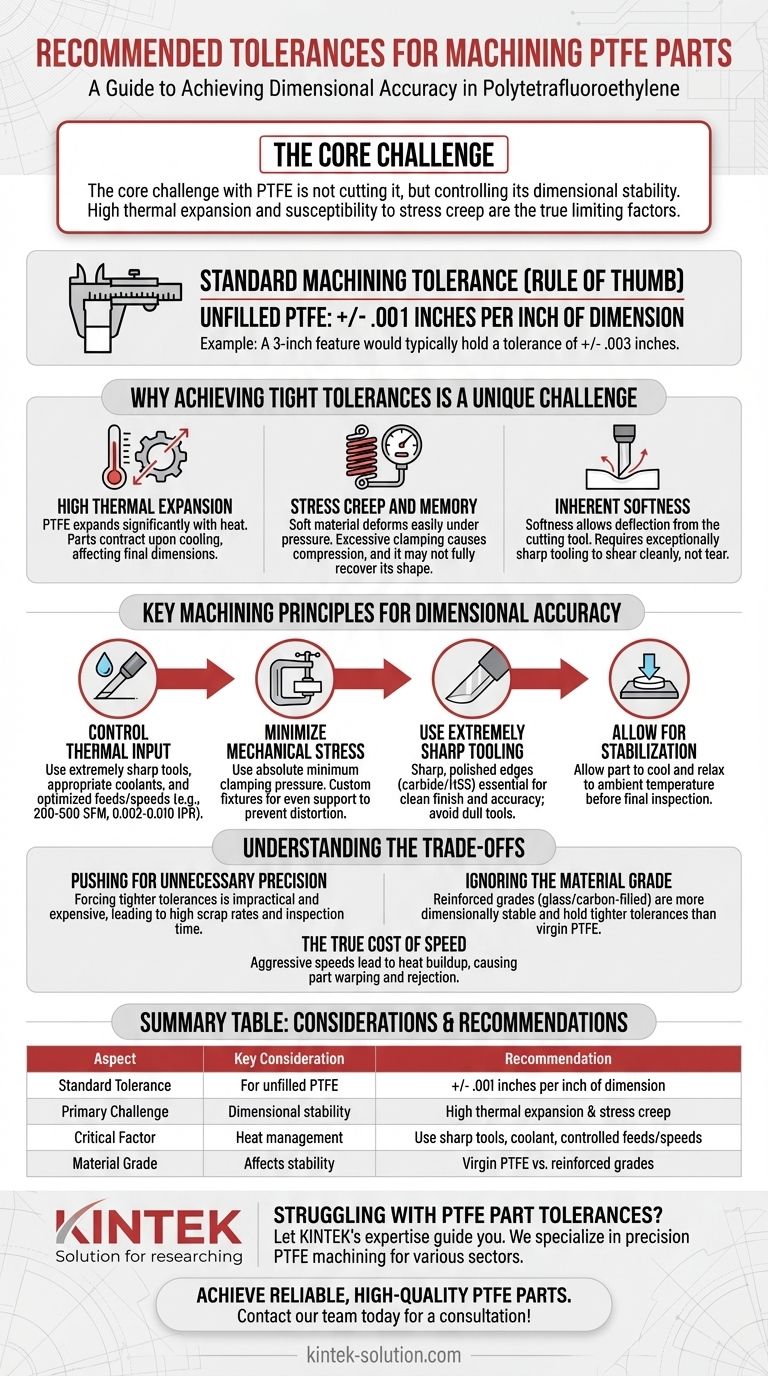

As a reliable rule of thumb, the standard machining tolerance for unfilled PTFE (Polytetrafluoroethylene) is +/- .001 inches per inch of dimension. For example, a 3-inch feature would typically hold a tolerance of +/- .003 inches. While tighter tolerances are possible, achieving them requires a deep understanding of the material's unique behavior and specialized machining techniques.

The core challenge with PTFE is not cutting it, but controlling its dimensional stability. While its softness makes it easy to machine, its high thermal expansion and susceptibility to stress creep are the true limiting factors in achieving tight tolerances.

Why Achieving Tight Tolerances in PTFE is a Unique Challenge

Successfully machining PTFE involves working with its properties, not against them. Several inherent characteristics make it fundamentally different from metals or more rigid plastics.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion. The heat generated during the cutting process, even if minor, will cause the material to expand significantly. As the part cools to ambient temperature, it will contract, meaning the final dimension may not be what was measured on the machine.

Stress Creep and Memory

This material is soft and deforms easily under pressure. Excessive clamping force during machining will compress the part. When released, it may not fully return to its original shape, a phenomenon known as stress creep. This makes workholding a critical variable.

Inherent Softness

While softness makes PTFE easy to cut, it also means the material can deflect away from the cutting tool if not properly supported. It also requires exceptionally sharp tooling to shear cleanly rather than push or tear the material.

Key Machining Principles for Dimensional Accuracy

Controlling the unique properties of PTFE hinges on a disciplined approach to the machining process. Success is less about aggressive material removal and more about finesse.

Control Thermal Input

Managing heat is the single most important factor. This is achieved by using extremely sharp tools (carbide-tipped are preferred), appropriate coolants, and optimized feeds and speeds. Recommended cutting speeds are often in the range of 200-500 surface feet per minute with a feed rate of 0.002" to 0.010" per revolution.

Minimize Mechanical Stress

Use the absolute minimum clamping pressure required to hold the part securely. Custom fixtures that support the workpiece evenly are often necessary to prevent distortion. Avoid overtightening vises or chucks.

Use Extremely Sharp Tooling

Dull tools generate excess friction and heat, and they tend to push the material rather than cutting it cleanly. Sharp, polished cutting edges, preferably on carbide or high-speed steel (HSS) tools, are essential for a clean surface finish and dimensional accuracy.

Allow for Stabilization

After machining, the part must be allowed to cool and relax to a stable ambient temperature before performing final inspection and measurement. Measuring a part while it is still warm from cutting will produce inaccurate results.

Understanding the Trade-offs

Designing for PTFE without considering its limitations leads to unnecessary cost and high scrap rates.

Pushing for Unnecessary Precision

Forcing tolerances tighter than the standard +/- .001" per inch on virgin PTFE is often impractical and expensive. This dramatically increases inspection time and the likelihood of part rejection.

Ignoring the Material Grade

The standard tolerance rule applies primarily to unfilled, virgin PTFE. Reinforced grades, such as glass-filled or carbon-filled PTFE, are far more dimensionally stable and can hold significantly tighter tolerances due to their reduced thermal expansion and creep.

The True Cost of Speed

Attempting to machine PTFE with the same aggressive speeds and feeds used for other materials is a common mistake. The time saved in cutting is quickly lost to rejected parts that have warped or moved out of tolerance due to heat buildup.

Making the Right Choice for Your Design

Your application's specific requirements should dictate your approach to PTFE tolerance.

- If your primary focus is standard components: Design your part with the +/- .001" per inch rule in mind from the start to ensure cost-effective manufacturability.

- If your application requires tighter tolerances: Specify a stable, reinforced PTFE grade and consult with an experienced machinist about the feasibility and cost implications.

- If you are machining the part yourself: Prioritize heat and pressure control above all else by using sharp tools, coolant, and minimal, evenly distributed clamping force.

Ultimately, successful PTFE machining comes from respecting the material's inherent properties rather than fighting against them.

Summary Table:

| Aspect | Key Consideration | Recommendation |

|---|---|---|

| Standard Tolerance | For unfilled PTFE | +/- .001 inches per inch of dimension |

| Primary Challenge | Dimensional stability | High thermal expansion & stress creep |

| Critical Factor | Heat management | Use sharp tools, coolant, and controlled feeds/speeds |

| Material Grade | Affects stability | Virgin PTFE vs. reinforced grades (glass/carbon-filled) |

Struggling with PTFE part tolerances? Let KINTEK's expertise guide you.

We specialize in machining precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. Our deep understanding of PTFE's unique behavior allows us to deliver the dimensional stability your application requires, from prototypes to high-volume production.

We help you:

- Apply the right tolerances for cost-effective manufacturability.

- Select the optimal PTFE grade (virgin or reinforced) for your needs.

- Leverage specialized techniques to control thermal expansion and stress creep.

Achieve reliable, high-quality PTFE parts. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications