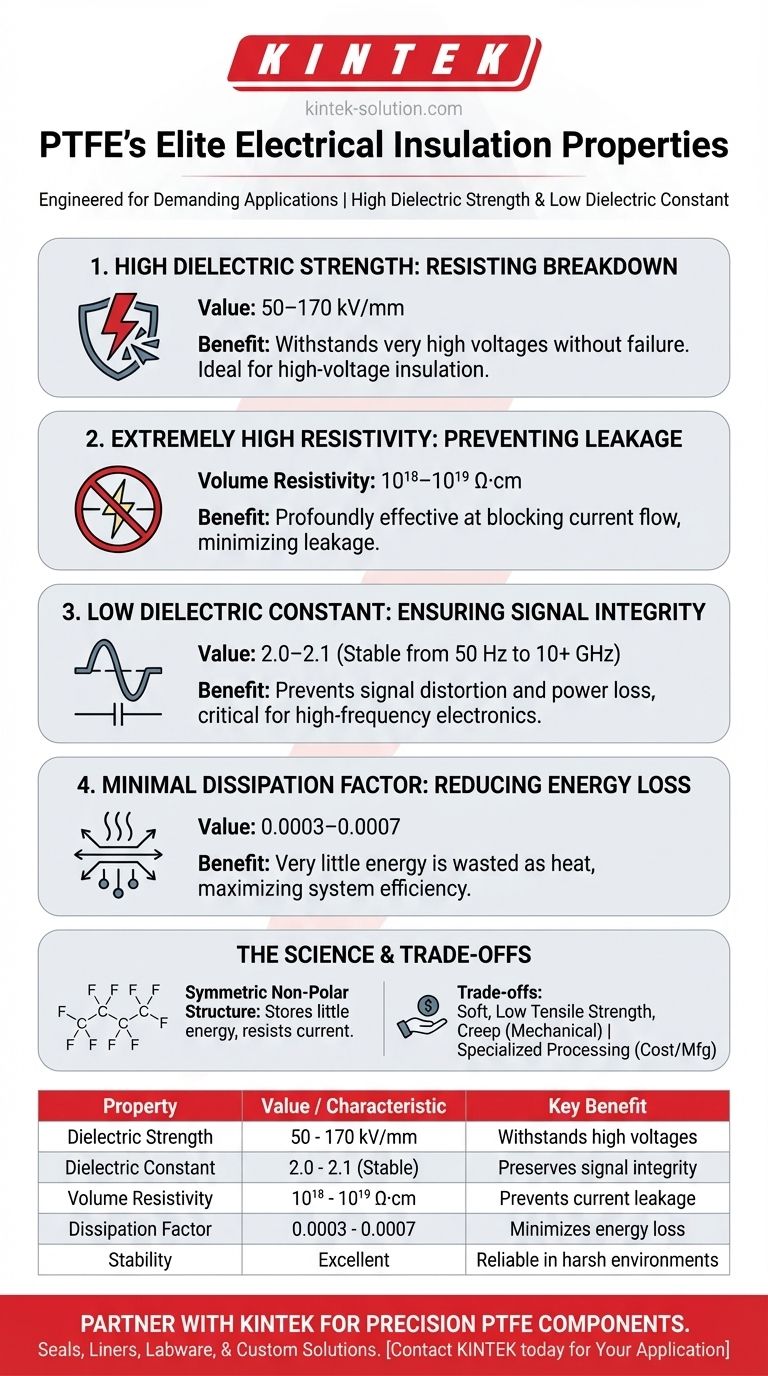

Polytetrafluoroethylene (PTFE) is one of the most effective electrical insulators available for demanding applications. Its performance is defined by a combination of high dielectric strength, meaning it can withstand very high voltages, and an extremely low dielectric constant, which preserves signal integrity in high-frequency electronics. These properties remain remarkably stable across a wide range of temperatures and frequencies.

The core reason for selecting PTFE is not just its excellent insulation numbers, but its unique consistency. Its electrical properties change very little under thermal stress or across the frequency spectrum, making it a highly reliable and predictable choice for critical components.

Deconstructing PTFE's Electrical Performance

To understand why PTFE is a superior insulator, we must look at its key performance metrics individually. Each one addresses a different aspect of electrical stress.

High Dielectric Strength: Resisting Electrical Breakdown

Dielectric strength measures a material's ability to withstand high voltage before it fails and allows current to pass through.

PTFE's dielectric strength is exceptionally high, typically ranging from 50 to 170 kV/mm. This means a 1 mm thick sheet of PTFE could theoretically withstand up to 170,000 volts, making it ideal for high-voltage wire insulation and transformer components.

Extremely High Resistivity: Preventing Current Leakage

Resistivity measures how strongly a material opposes the flow of electric current. Higher values mean better insulation.

PTFE exhibits incredibly high volume resistivity (10¹⁸-10¹⁹ Ω·cm) and surface resistivity (10¹⁷ Ω/sq). These figures indicate that it is profoundly effective at preventing current leakage, both through the bulk of the material and across its surface.

Low Dielectric Constant: Ensuring Signal Integrity

The dielectric constant indicates how much electrical energy a material can store in an electric field. For insulation in high-frequency applications, a lower number is better.

PTFE has a very low dielectric constant of 2.0 to 2.1. Crucially, this value remains stable across a vast frequency range (from 50 Hz to over 10 GHz). This prevents signal distortion and power loss, making it the material of choice for coaxial cables, microwave circuits, and high-speed PCBs.

Minimal Dissipation Factor: Reducing Energy Loss

The dissipation factor, or loss tangent, quantifies how much electrical energy is lost as heat within the insulating material.

PTFE's dissipation factor is extremely low, around 0.0003 to 0.0007. This means very little signal energy is wasted as heat, ensuring maximum efficiency in high-frequency electronic systems where every bit of power counts.

The Science Behind the Performance

PTFE's elite electrical properties are not accidental; they are a direct result of its unique molecular structure and chemical composition.

The Role of Molecular Structure

PTFE's macromolecules have a highly symmetric structure. The carbon backbone is tightly shielded by electronegative fluorine atoms.

This symmetrical arrangement and the strength of the carbon-fluorine bonds create a non-polar molecule. It does not easily align with an electric field, which is why it stores very little energy (low dielectric constant) and resists the flow of current (high resistivity).

Stability Across Environments

A key engineering advantage of PTFE is the consistency of its properties. Its electrical performance is largely unaffected by changes in temperature and frequency.

This reliability makes it suitable for applications in harsh environments where other insulators might see their performance degrade.

Understanding the Trade-offs

While its electrical properties are exceptional, PTFE is not the right choice for every situation. Its mechanical and manufacturing characteristics present important trade-offs.

Mechanical Limitations

PTFE is a relatively soft material with low tensile strength compared to other engineering plastics. It is also susceptible to "creep," or deformation under sustained load. This must be accounted for in any structural design.

Processing and Cost

PTFE has a very high melt viscosity, making it challenging to process using conventional melt-extrusion or injection molding techniques. This often requires specialized manufacturing processes, which can increase the final component cost compared to more common insulators like PVC or Polyethylene.

Making the Right Choice for Your Application

Selecting PTFE depends entirely on whether its premium electrical properties are necessary to meet your design goals.

- If your primary focus is high-frequency signal integrity (e.g., RF cables, microwave circuits): PTFE's extremely low and stable dielectric constant is its most valuable asset, preventing signal loss and distortion.

- If your primary focus is high-voltage insulation (e.g., wire wrapping, transformers): Its high dielectric strength and excellent thermal stability provide a robust and reliable barrier against electrical breakdown.

- If your primary focus is harsh environment reliability: PTFE's chemical inertness and consistent performance across a wide temperature range ensure dependability where other materials would fail.

Ultimately, PTFE's unique molecular structure gives it a combination of elite electrical properties that few other polymers can match.

Summary Table:

| Property | Value / Characteristic | Key Benefit |

|---|---|---|

| Dielectric Strength | 50 - 170 kV/mm | Withstands extremely high voltages |

| Dielectric Constant | 2.0 - 2.1 (stable from 50 Hz to 10+ GHz) | Preserves signal integrity in high-frequency circuits |

| Volume Resistivity | 10¹⁸ - 10¹⁹ Ω·cm | Prevents current leakage through the material |

| Dissipation Factor | 0.0003 - 0.0007 | Minimizes energy loss as heat |

| Temperature & Frequency Stability | Excellent | Reliable performance in harsh environments |

Need high-performance PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components leverage PTFE's superior electrical insulation properties to their fullest potential, guaranteeing reliability and performance in even the most demanding environments.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support