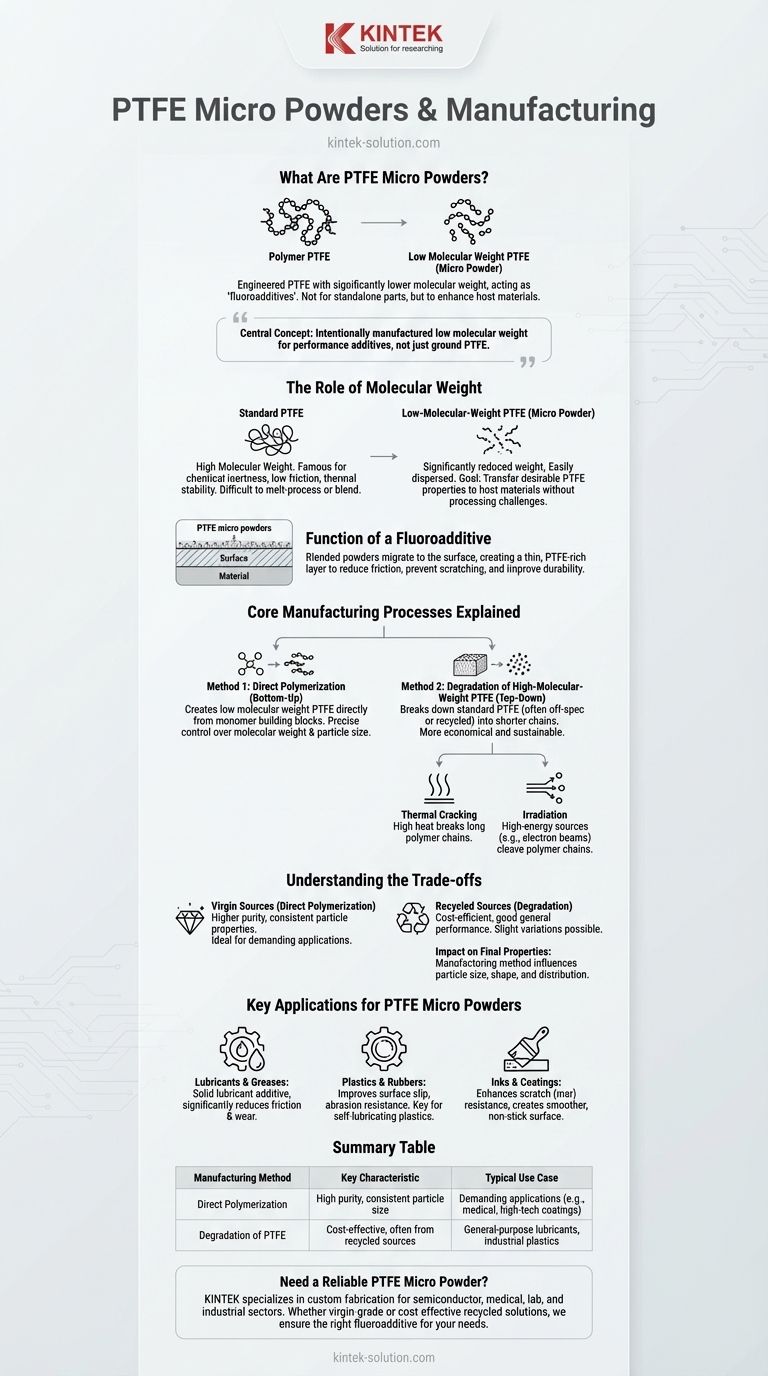

At its core, a PTFE micro powder is a specialized form of Polytetrafluoroethylene (PTFE) engineered with a significantly lower molecular weight than standard PTFE. Also known as fluoroadditives, these fine, white powders are not used to create standalone parts but are instead incorporated into other materials to enhance their properties, such as reducing friction or improving wear resistance.

The central concept to grasp is that PTFE micro powders are not simply ground-up PTFE. They are intentionally manufactured with low molecular weight to function as high-performance additives, transferring PTFE's unique characteristics to host materials like plastics, inks, and lubricants.

The Role of Molecular Weight in PTFE

Understanding Standard PTFE

Standard Polytetrafluoroethylene (PTFE) is a fluoropolymer with an extremely high molecular weight. This structure is responsible for its famous properties: exceptional chemical inertness, a very low coefficient of friction, and high-temperature stability.

However, this high molecular weight also makes it very difficult to melt-process or blend uniformly with other polymers and liquids.

Why Lower the Molecular Weight?

By significantly reducing the molecular weight, PTFE is transformed from a rigid, structural material into a fine powder. This low-molecular-weight PTFE, or micro powder, can be easily dispersed into other materials.

The goal is to lend the desirable properties of PTFE to a host material without the processing challenges of standard PTFE.

The Function of a Fluoroadditive

When blended into a product, these micro powders act as a fluoroadditive. They migrate to the surface of the host material during processing or use, creating a thin, PTFE-rich layer that reduces friction, prevents scratching, and improves overall durability.

Core Manufacturing Processes Explained

There are two primary routes to producing PTFE micro powders, each starting from a different point.

Method 1: Direct Polymerization

This method creates the low molecular weight PTFE directly from its monomer building blocks. It is a "bottom-up" approach that synthesizes the material to the desired specification from the start.

This process, typically controlled suspension or dispersion polymerization, offers precise control over the final molecular weight and particle size distribution.

Method 2: Degradation of High-Molecular-Weight PTFE

This is a "top-down" approach that begins with standard, high-molecular-weight PTFE and breaks it down. This source material is often off-spec resin or recycled PTFE waste, making it a more economical and sustainable option.

Two common degradation techniques are used.

Degradation via Thermal Cracking

In this process, high heat is used to break the long polymer chains of standard PTFE into the shorter chains required for micro powders.

Degradation via Irradiation

This technique uses high-energy sources, such as electron beams or gamma rays, to cleave the polymer chains. The controlled application of radiation effectively reduces the material's molecular weight to the target level.

Understanding the Trade-offs

Virgin vs. Recycled Sources

Micro powders produced via direct polymerization are considered virgin materials. They typically offer higher purity and more consistent particle properties, which is critical for highly demanding applications.

Powders made via degradation often come from recycled or scrap PTFE. While highly effective and more cost-efficient, they may have slight variations in purity or consistency compared to virgin powders.

Impact on Final Properties

The manufacturing method directly influences key characteristics like particle size, shape, and distribution. Direct polymerization allows for greater control over these factors, enabling the creation of powders tailored for specific uses.

Degradation methods can produce a wider range of particle sizes, which may be perfectly suitable for general-purpose applications but less ideal for those requiring extreme uniformity.

Key Applications for PTFE Micro Powders

The unique properties of these additives make them valuable in a wide range of industries.

In Lubricants and Greases

PTFE micro powders act as a solid lubricant additive, significantly reducing friction and wear in moving parts, especially under extreme pressure or temperature.

In Plastics and Rubbers

When compounded into thermoplastics, thermosets, and elastomers, these powders improve surface slip and abrasion resistance. They are a key ingredient in creating self-lubricating plastics for bearings and seals.

In Inks and Coatings

For printing inks and industrial coatings, adding PTFE micro powder enhances scratch resistance (mar resistance) and creates a smoother, non-stick surface. This improves the durability and finish of the final product.

Making the Right Choice for Your Goal

The ideal manufacturing method depends entirely on the performance requirements and cost constraints of the final application.

- If your primary focus is maximum purity and consistent performance: Direct polymerization is the superior choice for high-tech coatings, medical-grade plastics, or other demanding applications.

- If your primary focus is cost-effectiveness for general enhancement: Degradation of recycled PTFE provides an excellent balance of performance and value for industrial lubricants, general-purpose plastics, and many coatings.

Ultimately, PTFE micro powders are a versatile tool for imparting valuable fluoropolymer properties into a vast array of other materials.

Summary Table:

| Manufacturing Method | Key Characteristic | Typical Use Case |

|---|---|---|

| Direct Polymerization | High purity, consistent particle size | Demanding applications (e.g., medical, high-tech coatings) |

| Degradation of PTFE | Cost-effective, often from recycled sources | General-purpose lubricants, industrial plastics |

Need a reliable PTFE micro powder for your application? KINTEK specializes in manufacturing high-precision PTFE components, including custom micro powders tailored for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a virgin-grade powder for maximum performance or a cost-effective solution from recycled sources, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the right fluoroadditive for your needs. Contact us today to discuss how our PTFE solutions can enhance your product's performance and durability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs