To be clear, a PTFE-coated gasket is a standard rubber or metal gasket with a thin layer of Polytetrafluoroethylene (PTFE) applied to its surface. While this coating provides excellent non-stick properties and some chemical resistance at the surface, its primary limitations are significant: the coating can easily wear or flake off, it does not protect the underlying material from chemical attack, and it poses a contamination risk in high-purity systems.

The core issue is that a PTFE coating is a surface treatment, not a fundamental change to the gasket's properties. It attempts to lend the benefits of PTFE—like low friction and chemical inertness—to a more flexible core material, but the fragility of this coating makes it unsuitable for demanding or long-term applications.

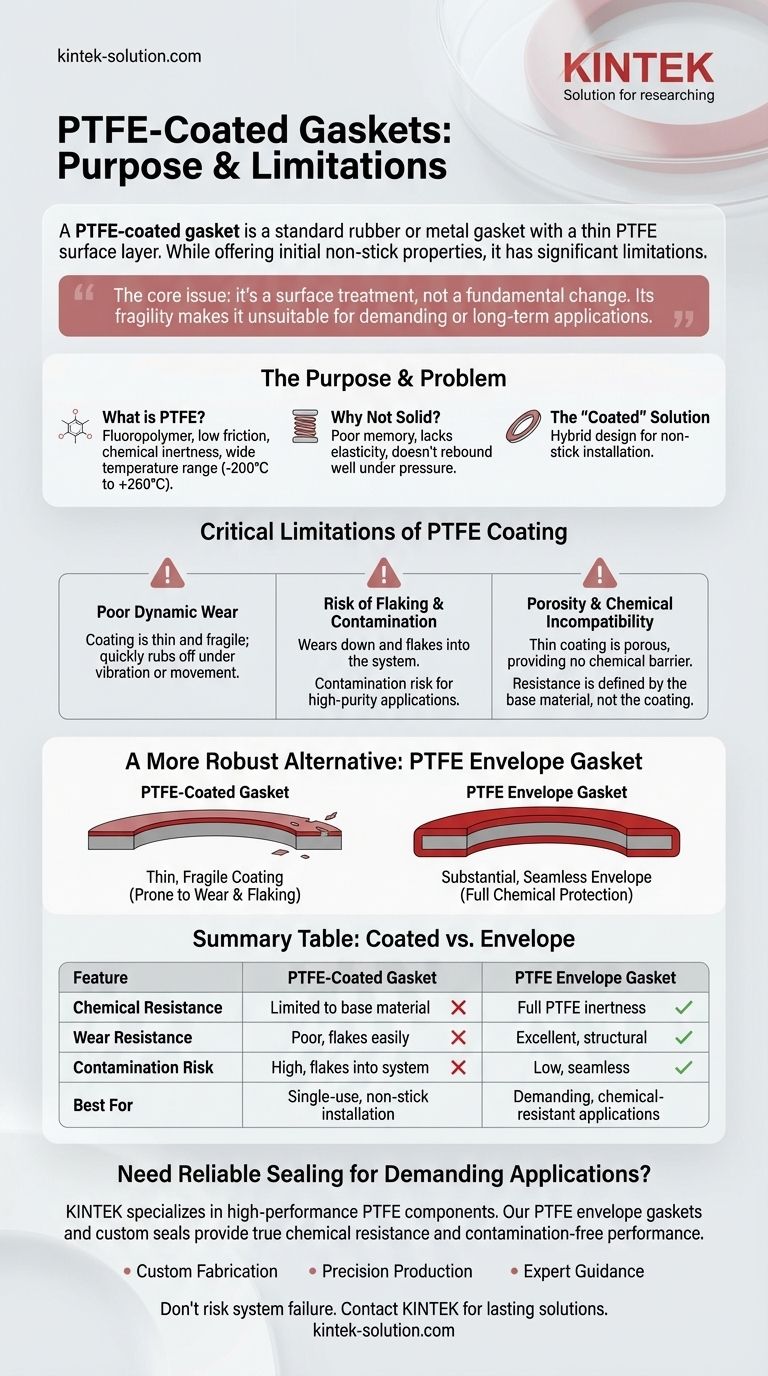

The Purpose and Problem of PTFE Gaskets

To understand the limitations of a coated gasket, we must first understand why PTFE is used at all and the inherent compromises involved.

What is PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer, a type of high-performance plastic. Its molecular structure gives it a unique combination of highly desirable properties.

These include an extremely low coefficient of friction (making it one of the most non-stick substances known), virtual immunity to chemical attack, and a very wide operating temperature range, from –200°C to +260°C (–328°F to +500°F).

Why Not Use Solid PTFE?

While its properties seem ideal, solid PTFE has one major drawback for sealing: it has poor "memory." It lacks the elasticity of rubber.

When compressed, a solid PTFE gasket does not rebound to its original shape effectively. This makes it less capable of maintaining a tight, resilient seal in applications with pressure or temperature fluctuations.

The "Coated" Solution

PTFE-coated gaskets were developed to create a hybrid solution. The goal is to combine the superior flexibility and sealing capability of a rubber or metal core with the non-stick, low-friction surface of PTFE.

This makes them useful as a one-time aid for installation, preventing the gasket from sticking to flange surfaces.

The Critical Limitations of a PTFE Coating

The compromise of using a thin coating introduces several points of failure that are critical to understand before specifying these gaskets for an application.

Poor Dynamic Wear Resistance

The PTFE coating is extremely thin and fragile. In any application involving vibration, torsion, or dynamic movement, the coating will quickly rub off.

This means it cannot be relied upon for continuous low-friction performance. It primarily functions as a one-time-use lubricant during initial assembly.

The Risk of Flaking and Contamination

When the coating inevitably wears down, it doesn't just disappear. It flakes off into the system.

These microscopic pieces of PTFE become contaminants in the process fluid. This makes PTFE-coated gaskets entirely unsuitable for high-purity applications found in the pharmaceutical, food and beverage, or semiconductor industries.

Porosity and Chemical Incompatibility

A thin coating does not create an impermeable chemical barrier. It is porous and cannot protect the core gasket material from the process media.

Therefore, the chemical resistance of the entire gasket is defined by its base material, not the PTFE coating. If the underlying rubber is not compatible with the chemical being sealed, the gasket will fail regardless of the coating.

A More Robust Alternative: The PTFE Envelope Gasket

For applications requiring both flexibility and true chemical resistance, a different design is necessary.

What is an Envelope Gasket?

A PTFE envelope gasket is a composite design. It consists of a core insert material (chosen for its mechanical properties) that is fully enclosed within a much thicker, seamless "envelope" of PTFE.

How It Solves the Coating Problem

Unlike a fragile coating, the PTFE envelope is a substantial structural component of the gasket. The process media only ever touches this thick PTFE layer, providing the full chemical inertness and temperature resistance of solid PTFE.

At the same time, the inner core provides the mechanical strength and resilience that solid PTFE lacks, allowing the gasket to maintain a reliable seal under pressure.

Making the Right Choice for Your Goal

Selecting the correct type of gasket requires matching the design to the demands of the application.

- If your primary focus is a non-stick surface for a single, static installation: A PTFE-coated gasket can be a cost-effective choice to prevent the gasket from sticking to flanges.

- If your application involves vibration, re-use, or dynamic movement: Avoid PTFE-coated gaskets entirely, as the coating will quickly fail and flake off.

- If your primary focus is aggressive chemical resistance: A PTFE envelope gasket or a solid PTFE gasket is the correct choice, as the coating provides no meaningful chemical protection to the core material.

- If your system requires high purity: Never use PTFE-coated gaskets. The high risk of flaking and process contamination is unacceptable.

Understanding the fundamental difference between a thin surface coating and a structural PTFE envelope is the key to ensuring long-term system integrity and performance.

Summary Table:

| Feature | PTFE-Coated Gasket | PTFE Envelope Gasket |

|---|---|---|

| Chemical Resistance | Limited to base material | Full PTFE chemical inertness |

| Wear Resistance | Poor, flakes easily | Excellent, structural envelope |

| Contamination Risk | High, flakes into system | Low, seamless construction |

| Best For | Single-use, non-stick installation | Demanding, chemical-resistant applications |

Need a reliable sealing solution for demanding applications?

At KINTEK, we specialize in high-performance PTFE components for semiconductor, medical, laboratory, and industrial applications. Unlike fragile coated gaskets, our PTFE envelope gaskets and custom seals provide true chemical resistance and contamination-free performance.

We offer:

- Custom fabrication from prototypes to high-volume orders

- Precision production ensuring reliable, long-term performance

- Expert guidance to select the right sealing solution for your specific needs

Don't risk system failure with inadequate gaskets. Contact our experts today to discuss your application requirements and get a solution that delivers lasting performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support