PTFE O-rings are specified for the most demanding sealing applications, particularly where chemical inertness and extreme temperature tolerance are critical. You will commonly find them providing static seals in industrial components like valve stems, flanges, pumps, and pipe joints across the chemical processing, aerospace, and pharmaceutical industries.

The core reason for choosing a PTFE O-ring is its material properties, not its physical flexibility. It is selected for its unparalleled ability to survive aggressive chemicals and extreme temperatures in static applications where traditional rubber seals would fail.

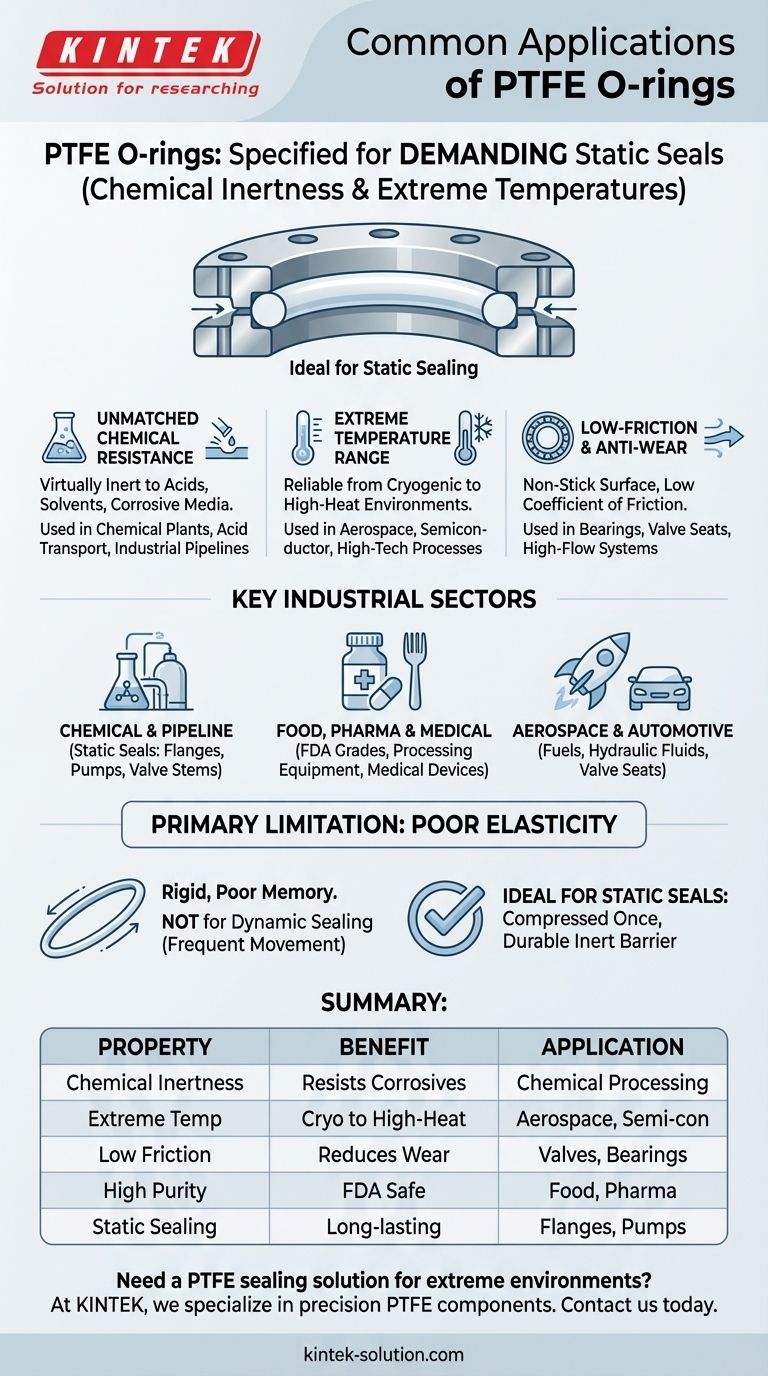

Why PTFE Excels in Extreme Environments

Understanding the unique properties of Polytetrafluoroethylene (PTFE) is key to understanding its applications. Unlike a typical rubber O-ring, PTFE is a fluoroplastic with a distinct set of advantages.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential material in environments where corrosion is a primary concern.

It is the default choice for equipment used in chemical manufacturing plants, acid transport systems, and industrial pipelines handling aggressive media.

Wide Temperature Operating Range

This material maintains its integrity across an exceptionally broad temperature spectrum. It performs reliably in cryogenic applications as well as in high-heat industrial processes.

This thermal stability is a key reason for its use in aerospace, semiconductor manufacturing, and other high-tech processes where temperature fluctuations are common.

Low-Friction and Anti-Wear Properties

Famously known by the brand name Teflon, PTFE has an extremely low coefficient of friction. This "non-stick" quality is highly valuable in certain mechanical applications.

In systems with high fluid flow rates, its low-friction surface resists wear. It is also used for components like bearings, valve seats, and piston rings where minimizing friction is a design goal.

Key Industrial Applications by Sector

The properties of PTFE directly translate to its use in specific, high-stakes industries where performance and reliability are non-negotiable.

Chemical and Pipeline Industries

This is the primary domain for PTFE seals. They are used extensively for static seals in flanges, covers, pumps, and valve stems.

Because PTFE can be machined into precise shapes and is chemically inert, it provides a reliable, long-lasting seal for pipes and containers that hold or transport reactive materials.

Food, Pharma, and Medical

PTFE is available in FDA-compliant grades, making it safe for contact with food and pharmaceuticals. Its non-reactive nature ensures it will not contaminate the product.

It withstands aggressive cleaning and sterilization processes, so it's frequently used in processing equipment, container lids, catheters, surgical instruments, and other medical devices.

Aerospace and Automotive

In aerospace, PTFE's ability to handle extreme temperatures and resist corrosive fuels and hydraulic fluids is critical.

In the automotive sector, it is used for valve seats, bearings, and seals where its chemical resistance and low-friction properties improve efficiency and component lifespan.

Understanding the Primary Limitation: Static Sealing

While its material properties are exceptional, PTFE has a critical mechanical limitation that defines its primary use case.

The Challenge of Elasticity

PTFE is a relatively rigid plastic, not a flexible elastomer like nitrile or viton rubber. It has poor "memory," meaning it does not spring back to its original shape effectively after being compressed.

This lack of elasticity makes it generally unsuitable for dynamic sealing applications, where the seal must constantly adjust to movement.

Why Static Seals are the Ideal Use Case

A static seal is one where there is no movement between the sealing surfaces, such as between two fixed pipe flanges.

In these applications, the PTFE O-ring is compressed once upon installation and remains in that state. Its job is to act as a durable, inert barrier, a role it performs perfectly without needing to be elastic.

Making the Right Choice for Your Application

Use the material's core strengths to guide your decision.

- If your primary focus is aggressive chemical exposure or wide temperature ranges: PTFE is the default choice for static seals in pumps, valves, and flanges.

- If your primary focus is high purity for food or medical use: Specify an FDA-compliant grade of PTFE for seals and components in processing equipment and medical devices.

- If your primary focus is a dynamic seal with frequent movement: A standard PTFE O-ring is likely the wrong choice; consider an energized PTFE seal or a different elastomeric material entirely.

Ultimately, specifying a PTFE O-ring is a deliberate engineering choice for when survival in a harsh environment outweighs the need for mechanical flexibility.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists acids, solvents, and corrosive media | Chemical processing, pipelines |

| Extreme Temperature Range | Performs from cryogenic to high-heat environments | Aerospace, semiconductor manufacturing |

| Low Friction / Non-Stick | Reduces wear in high-flow systems | Valves, bearings, piston rings |

| High Purity (FDA Grades) | Safe for food, pharma, and medical use | Processing equipment, medical devices |

| Static Sealing Reliability | Long-lasting barrier in fixed assemblies | Flanges, pump housings, valve stems |

Need a PTFE sealing solution for extreme environments?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in custom fabrication ensures a perfect fit for your most demanding applications.

Contact us today to discuss how our PTFE O-rings and components can enhance the reliability and longevity of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs