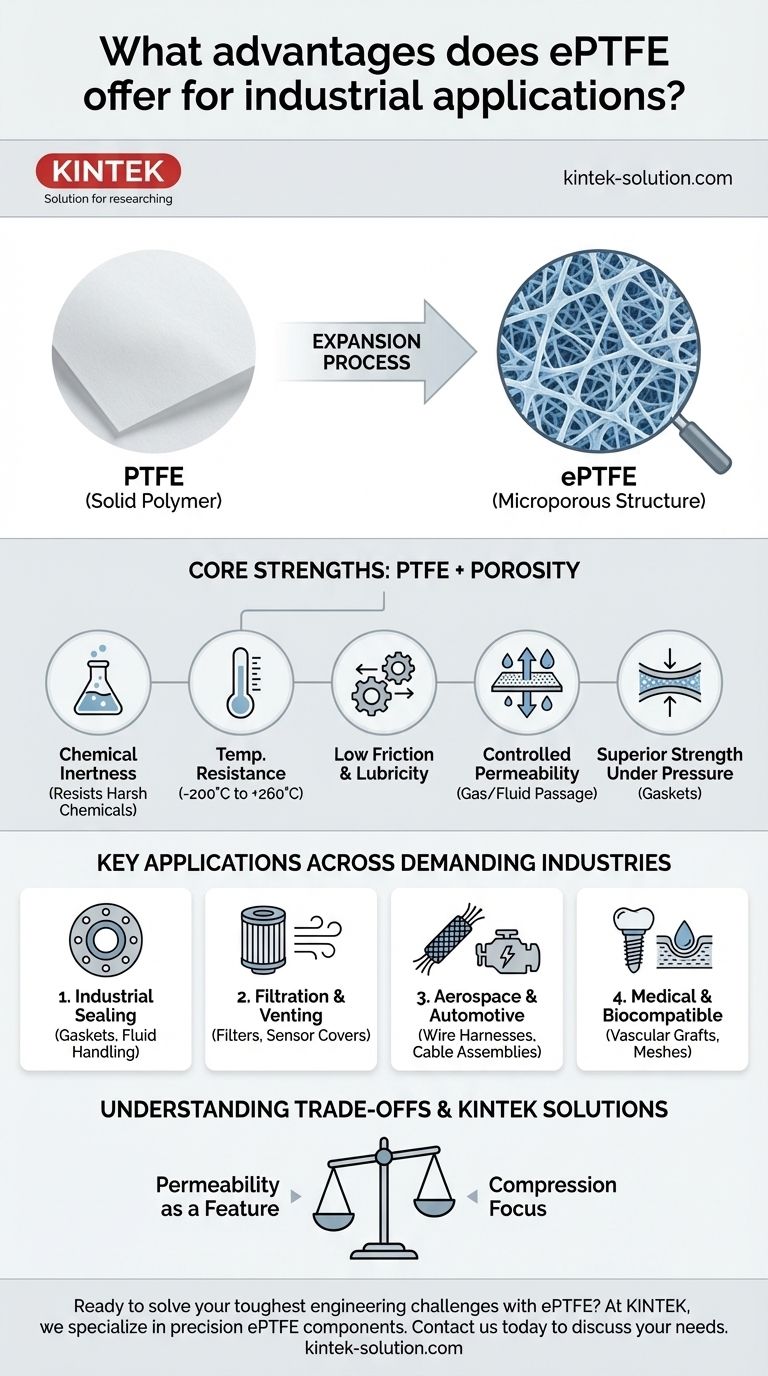

At its core, expanded Polytetrafluoroethylene (ePTFE) offers the exceptional chemical inertness, temperature resistance, and low-friction properties of standard PTFE, but enhances them with a unique microporous structure. This engineered porosity adds critical new capabilities, such as controlled permeability and superior strength under pressure, making it one of the most versatile high-performance materials available.

The key advantage of ePTFE is not just its individual properties, but the combination of them. It simultaneously acts as a robust barrier against harsh chemicals and extreme temperatures while allowing for the controlled passage of gases or fluids through its microscopic pores.

Beyond Standard PTFE: The Power of Expansion

The true value of ePTFE is understood by comparing it to its parent material, Polytetrafluoroethylene (PTFE). The manufacturing process that creates ePTFE fundamentally changes its physical structure and unlocks a wider range of applications.

From Solid to Microporous

Standard PTFE is a solid polymer. The "e" in ePTFE stands for expanded, a process that stretches the material, creating a web-like internal structure of nodes interconnected by fine fibers.

This process introduces a network of microscopic pores, transforming the solid material into a highly tunable, porous membrane.

Inheriting Core Strengths

ePTFE retains all the hallmark benefits of PTFE. This includes an extremely high resistance to chemical attack, thermal stability in temperatures from -200°C to +260°C, and one of the lowest coefficients of friction of any solid material (lubricity).

These base properties make it an automatic choice for applications in harsh or demanding environments.

Adding New Capabilities: Permeability and Strength

The fibrous, multi-directional structure is where ePTFE truly distinguishes itself. This network gives the material excellent mechanical integrity, especially under high surface pressure, making it ideal for high-performance gaskets.

Simultaneously, the microporosity allows for controlled permeability. This means it can be engineered to block liquids like water (hydrophobicity) while allowing air or other gases to pass through, a critical feature for venting and filtration.

Key Applications Across Demanding Industries

The unique combination of barrier properties and engineered porosity has made ePTFE indispensable in sectors where failure is not an option.

Industrial Sealing and Fluid Handling

ePTFE's ability to conform to surfaces under pressure makes it a superior material for gaskets and seals, especially for flange sealing in chemical or oxygen-carrying pipes.

It is also used for chemical barriers and low-pressure fluid passages where chemical inertness is paramount.

Filtration and Environmental Venting

The microporous structure is leveraged heavily in high-performance filters. Applications range from industrial fluid purification and aeration systems to environmental filtration technologies.

Its hydrophobic nature also makes it ideal for protective vents and sensor covers, which must shield sensitive electronics from liquids while allowing air to equalize pressure.

Aerospace and Automotive

In aerospace, ePTFE is used for durable wire harness sleeves and wicks that must withstand extreme temperature fluctuations and resist degradation.

Similarly, the automotive industry employs it in cable assemblies that require long-term durability and resistance to heat and chemicals.

Medical and Biocompatible Devices

ePTFE is highly biocompatible, meaning it can be safely used inside the human body without causing an adverse reaction.

Its porous structure is crucial for medical devices like vascular grafts and surgical meshes, as it allows for natural tissue integration, promoting healing while providing structural support.

Understanding the Trade-offs

While incredibly versatile, ePTFE is a specialized material, and selecting it requires acknowledging its specific characteristics.

Permeability is a Feature, Not a Flaw

The porosity that makes ePTFE excellent for filters and vents makes it unsuitable for applications requiring a truly absolute, non-porous seal against gases. The material must be specified with the correct density and pore size for the intended function.

Mechanical Considerations

While ePTFE performs exceptionally well under compression (like in a gasket), its tensile or abrasive strength may be lower than solid metals or certain engineering plastics. It is designed for specific mechanical loads.

Cost and Customization

As a high-performance, specialized polymer, ePTFE is more costly than commodity materials. Its high degree of customizability in density, thickness, and dimension is a key advantage but also contributes to its position as a premium material.

Making the Right Choice for Your Application

Selecting ePTFE is about matching its unique structural advantages to a specific engineering challenge.

- If your primary focus is gasketing and sealing: Leverage ePTFE's ability to conform under high pressure while providing a chemically inert barrier.

- If your primary focus is filtration or venting: Choose ePTFE for its controlled microporosity combined with its hydrophobic and high-temperature properties.

- If your primary focus is component protection in harsh environments: Rely on its extreme thermal stability and durability for applications like cable assemblies and sensor covers.

- If your primary focus is medical implantation: Utilize its proven biocompatibility and porous structure that encourages tissue integration.

By understanding its unique structural advantages, you can leverage ePTFE to solve challenges that conventional materials simply cannot address.

Summary Table:

| Key Advantage | Description | Common Applications |

|---|---|---|

| Chemical Inertness | Resists harsh chemicals and solvents. | Seals, gaskets, fluid handling components. |

| Controlled Permeability | Microporous structure allows gas/fluid passage while blocking liquids. | Filtration, protective vents, sensor covers. |

| High-Temperature Resistance | Stable from -200°C to +260°C. | Aerospace, automotive, industrial seals. |

| Biocompatibility | Safe for medical implantation and tissue integration. | Vascular grafts, surgical meshes. |

Ready to solve your toughest engineering challenges with ePTFE?

At KINTEK, we specialize in manufacturing precision ePTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures a solution tailored to your exact requirements.

Contact us today to discuss how our ePTFE components can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry