In corrosive environments, PTFE expansion bellows offer distinct, critical advantages over their metal counterparts. The primary benefits stem from PTFE's near-total chemical inertness, which prevents the corrosion and degradation that plague metal bellows when exposed to aggressive media. This inherent material advantage leads to a longer service life, reduced maintenance, and greater system reliability in chemically harsh applications.

While metal bellows are the standard for high-pressure and high-temperature service, their vulnerability to chemical attack makes PTFE the definitive choice for systems where corrosion resistance is the primary concern. The decision ultimately hinges on prioritizing chemical inertness and dynamic flexibility over raw structural strength.

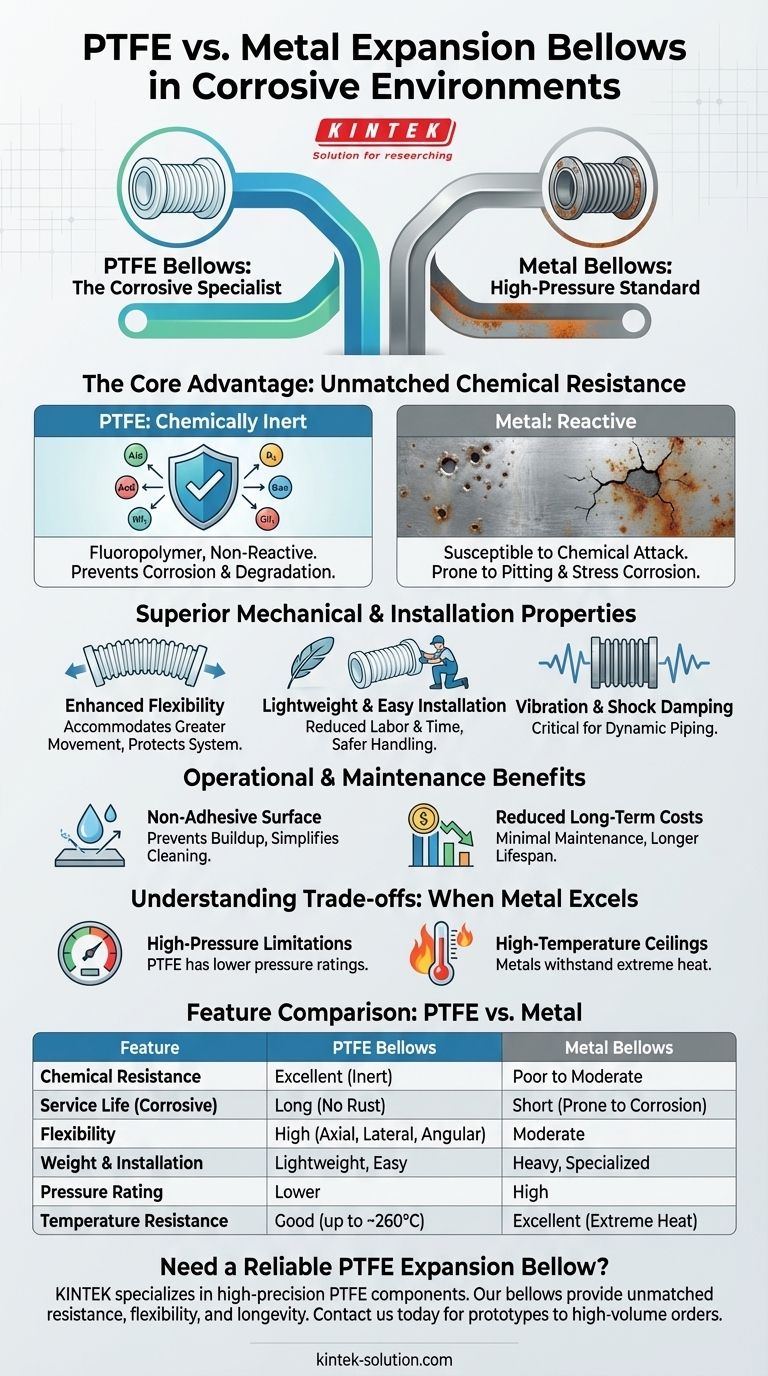

The Core Advantage: Unmatched Chemical Resistance

The fundamental reason to choose PTFE in a corrosive environment is its material composition. Unlike metals, which are reactive, PTFE is a fluoropolymer with exceptionally strong carbon-fluorine bonds.

Superior Material Inertness

PTFE is one of the most non-reactive substances known and is unaffected by the vast majority of industrial chemicals. This includes strong acids, bases, solvents, and saline solutions that would quickly corrode even specialized metal alloys.

Prevention of Corrosion and Degradation

Metal bellows are susceptible to various forms of corrosion, such as pitting, crevice corrosion, and stress corrosion cracking. PTFE simply does not rust, tarnish, or degrade from chemical exposure, ensuring its structural integrity over a much longer lifespan in these conditions.

Ideal for Harsh Service Environments

This chemical stability makes PTFE bellows the first-choice material for demanding industries. They are essential components in petrochemical pipelines, chemical processing plants, semiconductor manufacturing, and saline water treatment facilities.

Superior Mechanical and Installation Properties

Beyond chemical resistance, PTFE offers significant mechanical and handling benefits that simplify system design and reduce costs.

Enhanced Flexibility and Movement Absorption

PTFE is inherently more flexible than metal. This allows PTFE bellows to accommodate greater amounts of axial, lateral, and angular pipe movement without placing undue stress on the piping system, protecting pumps, vessels, and other critical equipment.

Lightweight and Simplified Installation

PTFE bellows are significantly lighter than their metal equivalents. This makes them easier and safer to handle, drastically reducing installation time and labor costs. Often, no specialized lifting equipment or tools are required.

Excellent Vibration and Shock Damping

The flexible nature of PTFE provides superior shock absorption and vibration damping. This is critical for protecting sensitive equipment from the operational stresses of a dynamic piping system.

Operational and Maintenance Benefits

The long-term value of PTFE bellows becomes clear when considering their entire operational lifecycle.

Non-Adhesive Surface Properties

PTFE has a non-stick, low-friction surface. This property prevents process media from adhering to the bellow walls, which is crucial for preventing material buildup, blockages, and contamination. This also simplifies system cleaning and ensures efficient fluid flow.

Reduced Long-Term Maintenance Costs

The combination of exceptional durability in corrosive environments and non-stick properties means PTFE bellows require minimal maintenance. Their long, reliable service life directly translates to lower replacement costs and less system downtime over time.

Understanding the Trade-offs: When Metal Excels

To make an informed decision, it is critical to recognize the applications where metal bellows remain the superior choice. Objectivity requires acknowledging limitations.

High-Pressure Limitations

Metal bellows possess far greater tensile strength, making them the default standard for high-pressure applications. Most PTFE bellows have lower pressure ratings and are not suitable for systems where high internal pressure is the primary design constraint.

High-Temperature Ceilings

Similarly, while PTFE has good thermal stability, metal alloys can withstand much higher temperatures. For extreme heat environments, such as steam lines or exhaust systems, metal bellows are the only viable option.

Making the Right Choice for Your System

Selecting the correct expansion bellow requires a clear understanding of your system's primary operational stressor.

- If your primary focus is maximizing lifespan in a corrosive chemical environment: PTFE is the clear and definitive choice due to its chemical inertness.

- If your primary focus is accommodating complex pipe movement or vibration: The superior flexibility of PTFE makes it the better option for protecting system components.

- If your primary focus is managing extreme pressure or temperature: Metal bellows are required for their raw strength and thermal resistance.

By correctly identifying your system's most critical challenge, you can select the expansion joint that ensures the long-term integrity, safety, and efficiency of your operations.

Summary Table:

| Feature | PTFE Bellows | Metal Bellows |

|---|---|---|

| Chemical Resistance | Excellent (inert to most acids, bases, solvents) | Poor to moderate (susceptible to corrosion) |

| Service Life in Corrosive Environments | Long (no rust or degradation) | Short (prone to pitting, cracking) |

| Flexibility & Movement Absorption | High (accommodates axial, lateral, angular movement) | Moderate |

| Weight & Installation Ease | Lightweight, easy to install | Heavy, requires specialized equipment |

| Pressure Rating | Lower | High |

| Temperature Resistance | Good (up to ~260°C / 500°F) | Excellent (withstands extreme heat) |

Need a reliable PTFE expansion bellow for your corrosive application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom expansion bellows, seals, and liners tailored for the semiconductor, medical, laboratory, and industrial sectors. Our bellows are engineered to provide unmatched chemical resistance, flexibility, and longevity in the harshest environments, reducing your maintenance costs and downtime.

Let us help you enhance your system's reliability. Contact our experts today to discuss your specific requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems