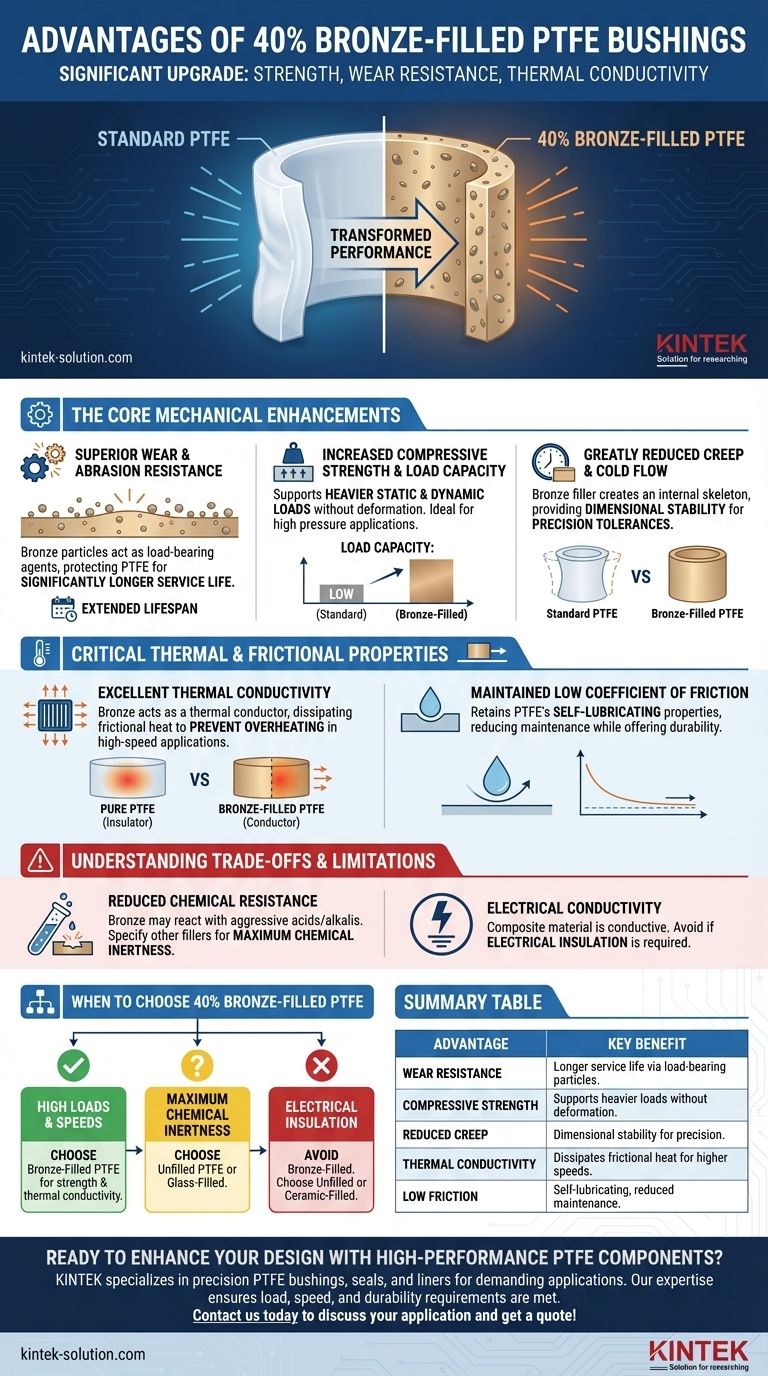

In short, 40% bronze-filled PTFE bushings offer a significant upgrade over standard PTFE by dramatically improving mechanical strength, wear resistance, and thermal conductivity. This transforms the naturally soft PTFE into a robust material capable of handling high loads and speeds while retaining its signature low-friction properties.

The core problem with pure PTFE is its tendency to deform or "creep" under pressure. Adding 40% bronze filler creates a composite material that resists this deformation, dissipates frictional heat, and withstands heavy wear, making it ideal for demanding mechanical applications.

The Core Mechanical Enhancements

Adding bronze particles into the PTFE matrix fundamentally changes its physical behavior, providing a rigid structure that overcomes the inherent softness of the base polymer.

Superior Wear and Abrasion Resistance

Bronze is a much harder material than PTFE. The bronze particles distributed throughout the bushing act as the primary load-bearing and wear-resistant agent, protecting the softer PTFE matrix from being rapidly worn away in high-contact applications.

This results in a significantly longer service life, especially in parts that experience continuous sliding or rotating motion.

Increased Compressive Strength and Load Capacity

Unfilled PTFE can be easily crushed or deformed under a heavy load. The bronze filler provides a substantial increase in compressive strength, allowing the bushing to support much heavier static and dynamic loads without being misshapen.

This makes it suitable for heavy-duty industrial machinery and automotive components where high pressure is common.

Greatly Reduced Creep and Cold Flow

Creep, or "cold flow," is the tendency of pure PTFE to slowly deform over time when under a sustained load, even at room temperature. The bronze filler creates an internal skeleton within the material, providing excellent dimensional stability and drastically reducing this effect.

Your components will maintain their critical tolerances for much longer, which is essential for precision applications.

Critical Thermal and Frictional Properties

While the mechanical upgrades are primary, the changes in thermal and electrical properties are equally important for performance in dynamic systems.

Excellent Thermal Conductivity

Pure PTFE is a thermal insulator, meaning it traps heat. In high-speed applications, frictional heat can build up and cause the bushing to fail. Bronze is an excellent thermal conductor.

The bronze filler provides a pathway for this heat to dissipate away from the sliding surface, preventing overheating and allowing the bushing to operate at higher speeds and loads.

Maintained Low Coefficient of Friction

Crucially, the addition of bronze does not eliminate the defining benefit of PTFE: its slipperiness. The material remains self-lubricating.

This means you get the durability of a much harder material combined with the low-friction performance of PTFE, eliminating the need for external lubrication and reducing maintenance.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Objectively understanding the downsides of bronze-filled PTFE is critical for proper material selection.

Reduced Chemical Resistance

While still good, the chemical resistance of bronze-filled PTFE is lower than that of pure PTFE. Bronze can react with certain corrosive chemicals that would not affect the base polymer.

Therefore, for applications involving aggressive acids or alkalis, a different filler (like glass) or unfilled PTFE may be a better choice.

Electrical Conductivity: A Key Consideration

Pure PTFE is an excellent electrical insulator. Bronze, being a metal, is electrically conductive. Adding it to PTFE makes the composite material conductive as well.

This is a critical disadvantage if your application requires electrical insulation. However, it can be an advantage in applications where you need to prevent the buildup of static electricity.

When to Choose 40% Bronze-Filled PTFE

Use this simple guide to determine if this material aligns with your primary design goal.

- If your primary focus is high loads and high speeds: Bronze-filled PTFE is an excellent choice due to its high compressive strength and superior thermal conductivity.

- If your primary focus is maximum chemical inertness: You should specify unfilled PTFE or a version with a more inert filler, such as glass fiber.

- If your primary focus is electrical insulation: You must avoid bronze-filled PTFE and select an unfilled or ceramic-filled grade instead.

Choosing the right material from the start is the foundation of a reliable and long-lasting mechanical design.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Wear Resistance | Bronze particles act as a hard, load-bearing filler for longer service life. |

| Compressive Strength | Supports much heavier static and dynamic loads without deformation. |

| Reduced Creep/Cold Flow | Bronze filler provides dimensional stability for precision applications. |

| Thermal Conductivity | Dissipates frictional heat, allowing for higher operating speeds and loads. |

| Low Friction | Maintains PTFE's self-lubricating properties, reducing maintenance. |

Ready to enhance your design with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE components, including custom bronze-filled bushings, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions from prototypes to high-volume orders.

Our expertise ensures your components meet the demanding requirements for load, speed, and durability. Contact us today to discuss your specific application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments